Electric spark yarn singeing machine

A technology of electric spark and singeing machine, used in textiles and papermaking, etc., can solve the problems of product quality decline, high heat loss, affecting the quality of yarn singeing, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

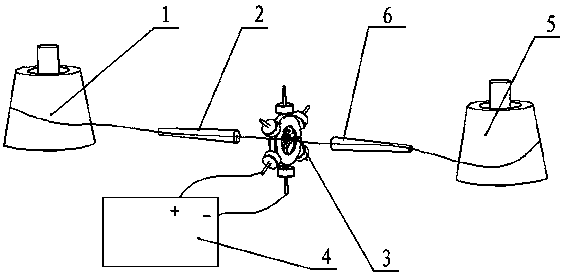

[0011] Such as figure 1 and figure 2 As shown, an EDM yarn singeing machine includes a yarn loading and unwinding device 1, a first yarn guiding device 2, an EDM discharger 3, an EDM generator 4, a second yarn guiding device 6, Yarn return device 5.

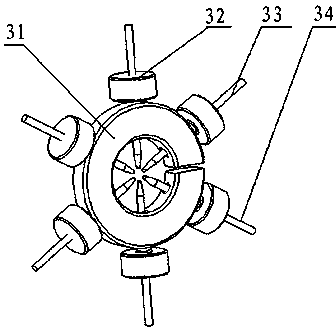

[0012] The spark arrester 3 comprises an annular body 31, and three positive poles 33 and three negative poles 34 are arranged on the periphery of the annular body 31, and all positive poles 33 and negative poles 34 are alternately arranged; a positive pole 33 and adjacent to the positive pole 33 A negative pole 34 forms a pair of electrodes, and the spark generator 4 is connected with the positive pole 33 and the negative pole 34 on the spark arrester 3 .

[0013] The yarn to be processed is drawn out from the yarn retracting device 1, guided through the first yarn guiding device 2 and the second yarn guiding device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com