Measuring method for displacement efficiency of simulated well cementation cementing

A technology of displacement efficiency and measurement method, which is applied in the direction of measurement, measurement device, fluid velocity measurement, etc., can solve the problems of displacement efficiency error, measurement method limitation, lack of replacement liquid and the replacement process of the displaced liquid, etc., to achieve investment Low cost, good versatility, and the effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

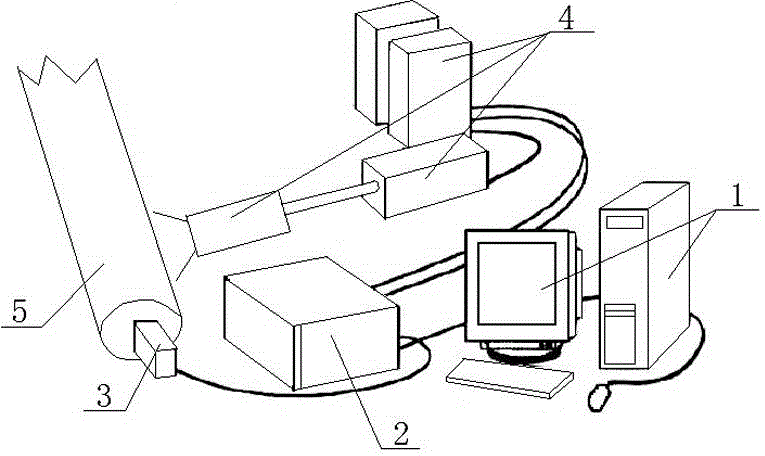

[0017] See figure 1 , The present invention includes the following steps:

[0018] 1). Taking the PIV system including the computer 1, the signal processor 2, the CCD camera 3 and the laser 4 as the measuring equipment, the CCD camera 3 of the PIV system is required to be arranged on the top of the simulated wellbore 5, and the laser 4 of the PIV system is arranged on the simulated wellbore The measurement section of 5 makes the CCD camera 3 and the laser 4 perpendicular to each other when measuring the flow field;

[0019] 2). Inject the displaced fluid (mud-similar fluid) and displacement fluid (cement-slurry-similar fluid) into the annulus formed by the casing and wellbore of the simulated wellbore 5. The displaced fluid and the displacement fluid are required to be transparent, and Disperse tracer particles in the flow field of the displacement fluid;

[0020] 3). The laser 4 of the PIV system emits a piece of light that illuminates the flow field measurement area, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com