Method and device for detecting failure of urea injection system

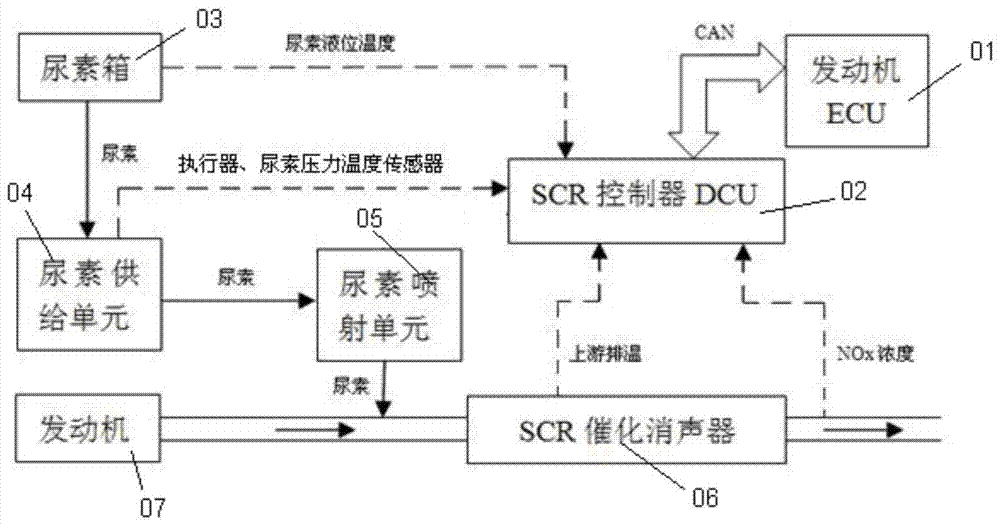

A urea injection system and urea injection technology are applied in the direction of electric control of exhaust treatment devices, diagnostic devices of exhaust treatment Plug-in installation is not firm and other problems, to achieve a good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

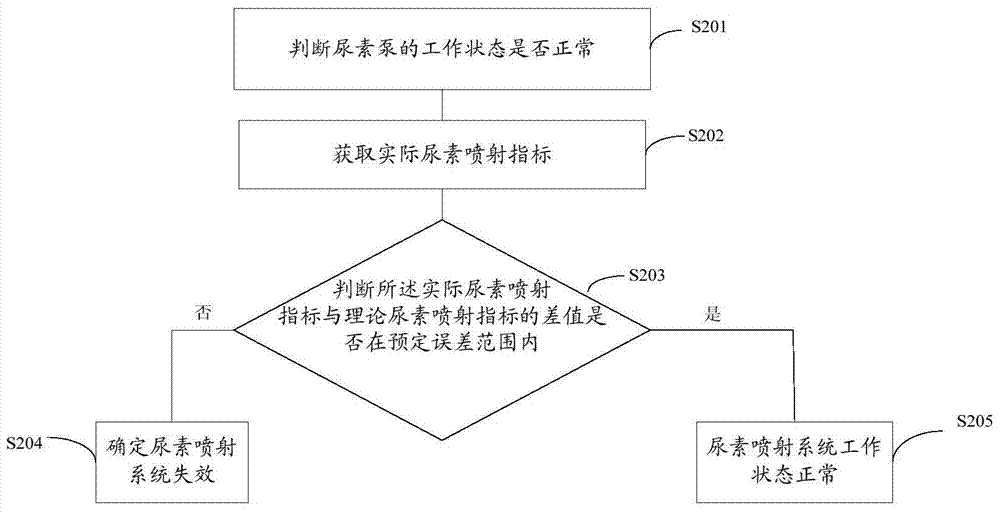

[0036] figure 2 It is a schematic flowchart of the detection method for failure of the urea injection system in Embodiment 1 of the present invention.

[0037] S201, judging whether the working state of the urea pump is normal:

[0038] Specifically, by checking whether the CAN bus communication of the urea injection system is normal, whether the auxiliary air pressure is normal, etc., it is judged whether the working state of the urea pump is in good condition. If it is determined that the working state of the urea pump is normal, step S202 is executed.

[0039] S202. Obtain the actual urea injection index:

[0040] It should be noted that the urea injection index described in this embodiment is a representation of the amount of urea injected by the urea injection system. Specifically, the urea injection index can be the urea injection amount under predetermined working conditions, or the urea injection pressure of the urea pump at a predetermined operating frequency, or ...

Embodiment 2

[0078] see Figure 4 , Figure 4 It is the detection device for the failure of the urea injection system in the second embodiment. The detection device includes,

[0079] The first determination unit 41 is configured to determine that the urea pump is in a normal injection state;

[0080] An acquisition unit 42, configured to acquire an actual urea injection index;

[0081] A judging unit 43, configured to judge whether the difference between the actual urea injection index and the theoretical urea injection index is within a predetermined error range;

[0082] The second determining unit 44 is configured to determine that the urea injection system fails when the difference between the actual urea injection index and the theoretical urea injection index is not within a predetermined error range.

[0083] Further, the urea injection index includes the urea injection amount at the outlet of the urea pump.

[0084] Further, the urea injection index includes, under predetermi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com