Low-flash-point liquid nitrogen protection system

A liquid nitrogen and protection system technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of volatile and high requirements, and achieve the effects of protecting safety, improving production safety, and improving disposal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

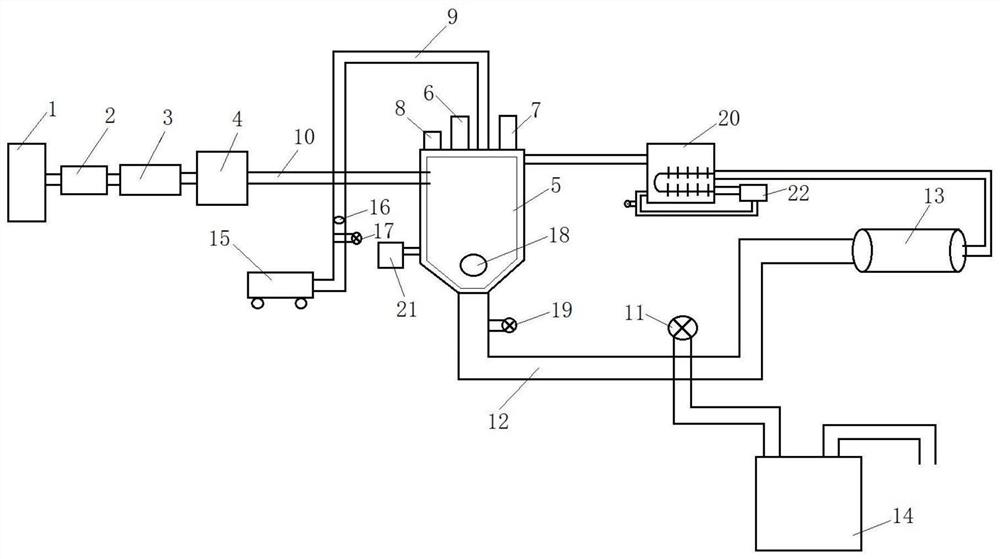

[0025] Specific implementation mode one: see figure 1 This embodiment will be described. The low flash point liquid nitrogen protection system described in this embodiment includes a cryogenic liquid storage tank 1, a cryogenic liquid vaporizer 2, a tube-type water bath heater 3, a nitrogen storage tank 4, a hazardous waste storage tank 5, auxiliary fuel and volatile lightning Ground liquid waste switching gate 11, brick kiln 13, auxiliary fuel storage tank 14 and waste heat boiler 20,

[0026] The low-temperature liquid storage tank 1, the low-temperature liquid vaporizer 2, the tube-type water bath heater 3, the nitrogen storage tank 4 and the hazardous waste storage tank 5 are connected in sequence, and the hazardous waste storage tank 5 and the auxiliary fuel storage tank 14 are respectively connected to the brick kiln. 13, the hazardous waste storage tank 5 and the auxiliary fuel storage tank 14 are provided with auxiliary fuel and volatile lightning liquid waste switchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com