A hydraulic constant-speed power generation system for a multi-layer split-flow vertical axis fan

A vertical axis, hydraulic technology, applied in the field of multi-layer shunt type vertical axis fan hydraulic constant speed power generation system, can solve the problems of low wind energy utilization rate, insufficient flow, energy loss, etc., and achieve high wind energy utilization rate, high utilization efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

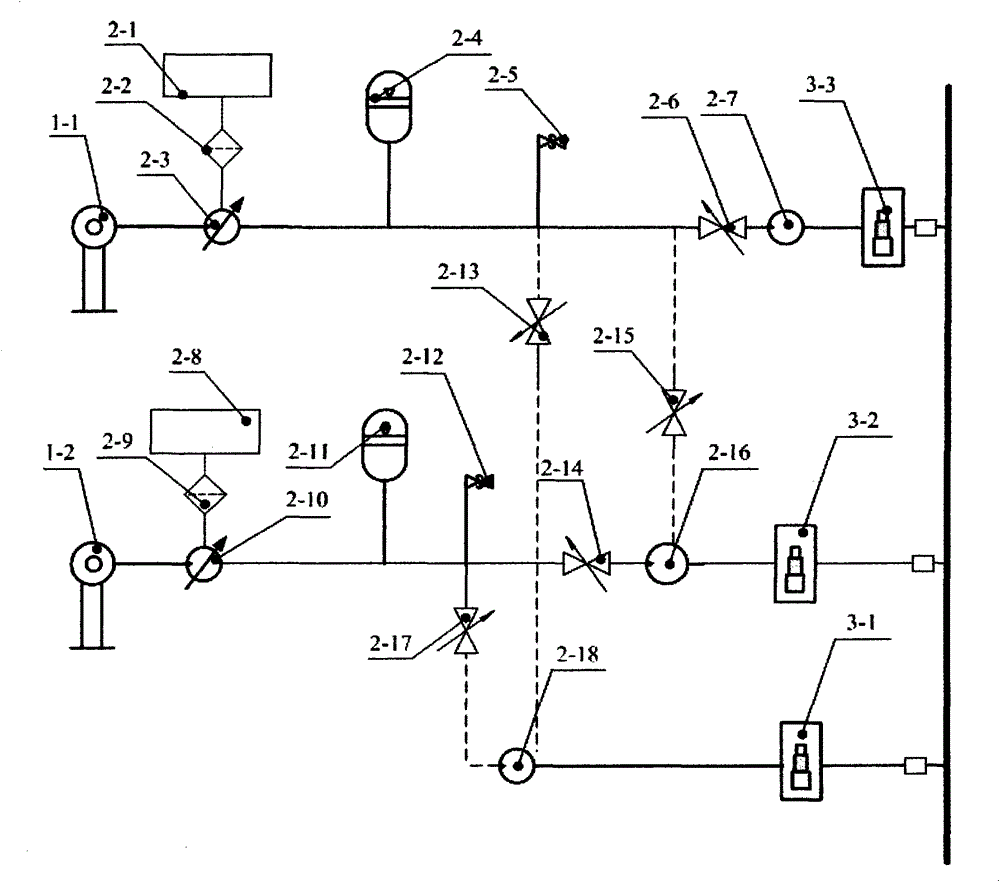

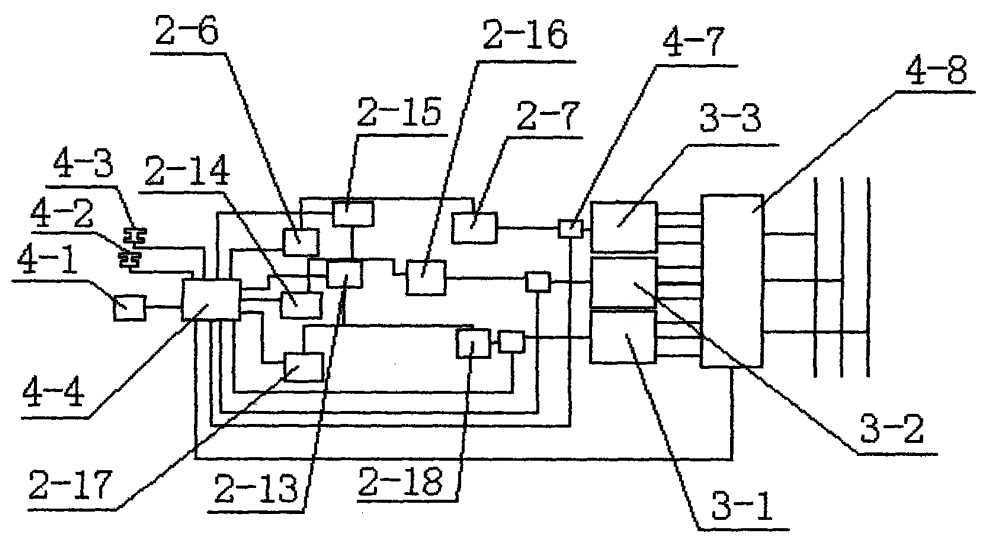

[0017] refer to figure 1 , figure 2 with image 3 A hydraulic constant-speed power generation system of a multi-layer shunt type vertical axis fan is shown, including a fan part, a hydraulic part, a power generation part and a control part, the fan part is connected to the hydraulic part, the hydraulic part is connected to the power generation part, and the The above-mentioned control part is respectively connected with the fan part, the hydraulic part and the power generation part.

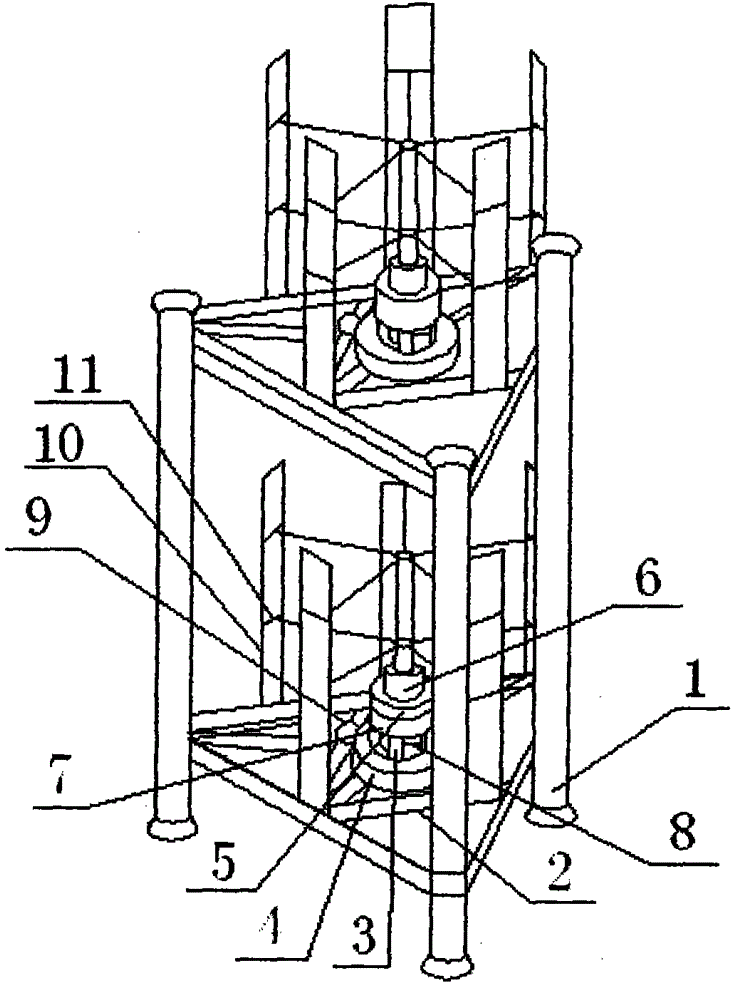

[0018] As a preferred technical solution, the fan part consists of a vertical axis wind wheel (10), a wind wheel flange (9), a wind wheel bearing seat (8), a wind wheel bearing cover (7), a bearing (6), a coupling device (11), coupling flange (5), hydraulic pump flange (3), hydraulic pump mounting plate (4), mounting base plate (2) and multi-layer tower (1), the coupling (11) Installed on the shaft of the vertical axis wind wheel (10), the wind wheel bearing seat (8), the wind wheel bearing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com