Triaxial rheological experimental device for tailings materials

A triaxial rheological, experimental device technology, applied in the direction of testing the strength of materials using a stable tension/compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

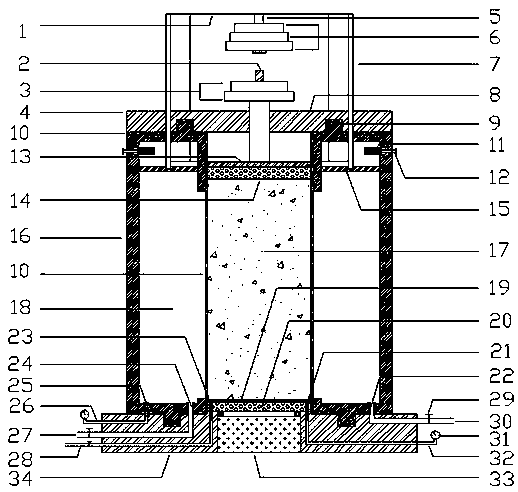

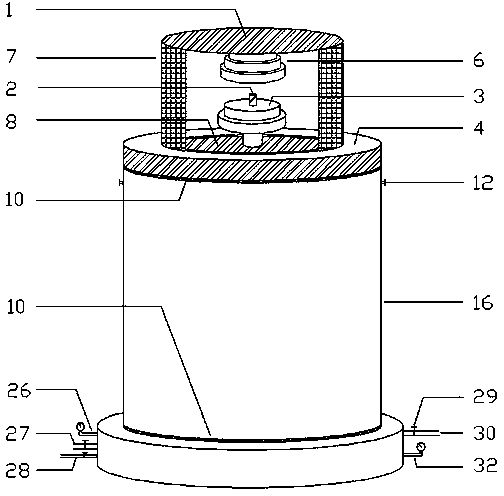

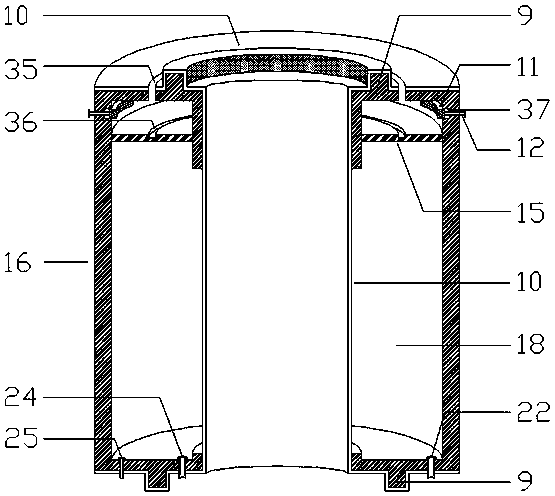

[0052] Implementation mode one: if Figure 1-6As shown, a triaxial rheological experimental device for tailings materials, including pressurized top plate 1, pressurized shaft 2, weight I3, outer cover 4, hook 5, weight II6, pressure transmission ring 7, inner cover 8. Convex groove 9, rubber film 10, snap ring 11, push-pull rod 12, pressure plate 13, upper baffle plate 14, pressure plate 15, pressure steel cylinder 16, pressure chamber 18, encrypted barbed wire 19, lower Diaphragm 20, pore water pressure measurement connection pipe 21, water injection pipe nail 22, pore water drainage connection pipe 23, drainage pipe nail 24, pressure measurement pipe nail 25, confining pressure pressure measurement pipe 26, drainage pipe 27, pore water drainage Pipe 28, water injection pipe 30, pore water pressure measuring pipe 32, vibrator 33, container bottom plate 34, pressure transmission ring reserved groove 35, pressure transmission ring connection groove 36, snap ring groove 37, vib...

Embodiment approach 2

[0068] Implementation mode two: if Figure 1-6 As shown, a triaxial rheological experimental device for tailings materials, including pressurized top plate 1, pressurized shaft 2, weight I3, outer cover 4, hook 5, weight II6, pressure transmission ring 7, inner cover 8. Convex groove 9, rubber film 10, snap ring 11, push-pull rod 12, pressure plate 13, upper baffle plate 14, pressure plate 15, pressure steel cylinder 16, pressure chamber 18, encrypted barbed wire 19, lower Diaphragm 20, pore water pressure measurement connection pipe 21, water injection pipe nail 22, pore water drainage connection pipe 23, drainage pipe nail 24, pressure measurement pipe nail 25, confining pressure pressure measurement pipe 26, drainage pipe 27, pore water drainage Pipe 28, water injection pipe 30, pore water pressure measuring pipe 32, vibrator 33, container bottom plate 34, pressure transmission ring reserved groove 35, pressure transmission ring connection groove 36, snap ring groove 37, vi...

Embodiment approach 3

[0076] Implementation mode three: if Figure 1-6 As shown, a triaxial rheological experimental device for tailings materials, including pressurized top plate 1, pressurized shaft 2, weight I3, outer cover 4, hook 5, weight II6, pressure transmission ring 7, inner cover 8. Convex groove 9, rubber film 10, snap ring 11, push-pull rod 12, pressure plate 13, upper baffle plate 14, pressure plate 15, pressure steel cylinder 16, pressure chamber 18, encrypted barbed wire 19, lower Diaphragm 20, pore water pressure measurement connection pipe 21, water injection pipe nail 22, pore water drainage connection pipe 23, drainage pipe nail 24, pressure measurement pipe nail 25, confining pressure pressure measurement pipe 26, drainage pipe 27, pore water drainage Pipe 28, water injection pipe 30, pore water pressure measuring pipe 32, vibrator 33, container bottom plate 34, pressure transmission ring reserved groove 35, pressure transmission ring connection groove 36, snap ring groove 37, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com