An Array Type Microhole Cathode Gas Discharge Plasma Jet Device

A technology of discharging plasma and cathode gas, which is applied in the directions of plasma and electrical components, can solve the problem of small jet area, and achieve the effect of increasing the area, ensuring the consistency of plasma characteristics and ensuring the consistency of characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

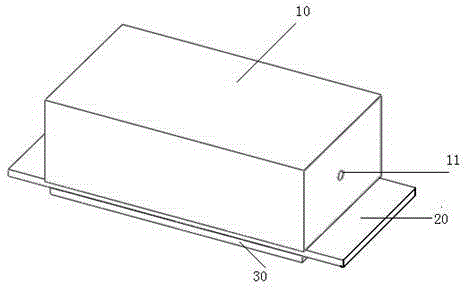

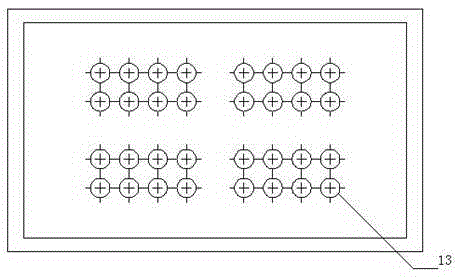

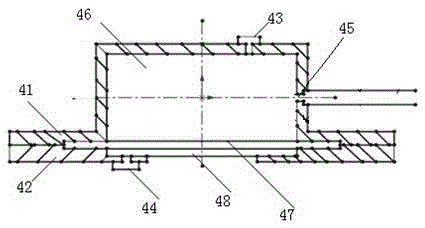

[0024] Examples: See figure 1 , figure 2 with image 3 , An array type microcavity cathode gas discharge plasma jet device, comprising a high-voltage electrode 10, an insulating dielectric layer 20, and a ground electrode 30 arranged from top to bottom. The high-voltage electrode 10 and the ground electrode 30 are made of conductive materials, The insulating medium layer 20 is made of insulating material; the high-voltage electrode 10 is a hollow box structure, the hollow part of the box structure is a high-voltage electrode gas storage cavity, and the box structure has gas storage for the high-voltage electrode The air inlet 11 in the cavity; the bottom of the box structure has multiple first through holes, the insulating dielectric layer 20 has multiple second through holes, and the ground electrode 30 has multiple third through holes, so The plurality of first through holes, the plurality of second through holes and the plurality of third through holes correspond one-to-on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com