Marine wind driven generator mounting and transporting spud leg mud discharging, air injecting and washing device and method

A technology of wind power generators and jet devices, which is applied to sheet pile walls, buildings, and foundation structure engineering. It can solve problems such as difficulty in determining the position of the water inlet, increasing the power of the ship's main engine, and increasing the displacement of the ship. It achieves simple structure and low weight. Light and drag-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

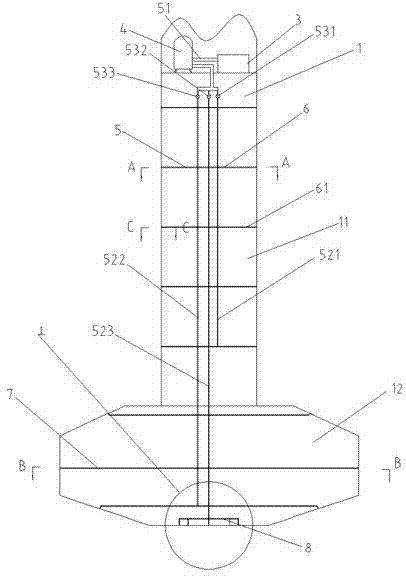

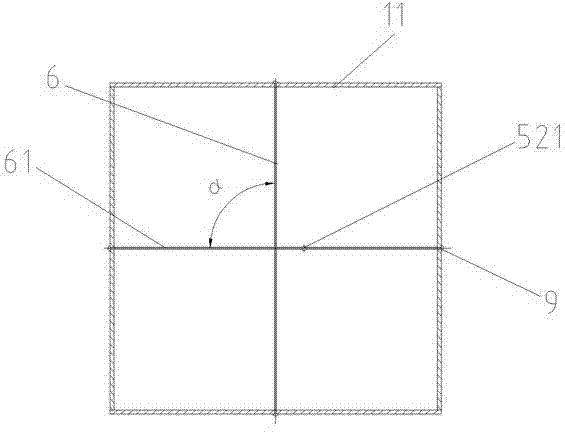

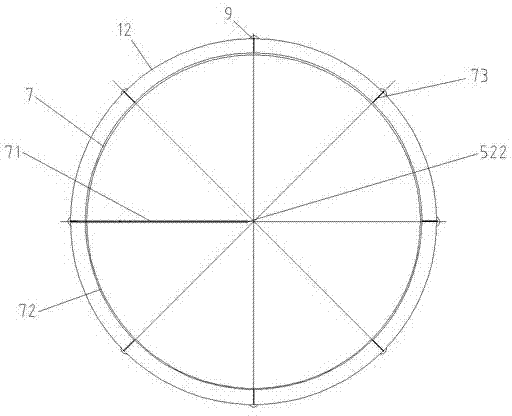

[0024] Such as figure 1 As shown, the leg 1 is assembled and welded by a vertically extending leg body 11 at the top and a spud can 12 extending laterally at the bottom to form an inverted T-shaped hollow steel structural member. The present invention includes a high-pressure air pump 3 arranged in the leg body 11, an air storage tank 4, a high-pressure gas connection piping system 5, several layers of leg body horizontal air injection devices 6, several layers of spud shoe horizontal air injection devices 7, and the bottom layer of the spud shoe. The jet device 8 and the high-pressure gas connection piping system 5 include a high-pressure gas main pipe 51, several vertical high-pressure gas branch pipes, and several electromagnetic shut-off valves. The high-pressure air pump 3 and the air storage tank 4 are arranged in the upper end of the leg body 11, and the air st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com