Device and method for manufacturing multi-segment filter rods for the tobacco processing industry

A processing industry, multi-segment technology, applied in tobacco, e-liquid filter elements, applications, etc., can solve problems such as increased scrap rate, machine obstruction, production interruption, etc., and achieve the effect of reliable truncation process and high operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

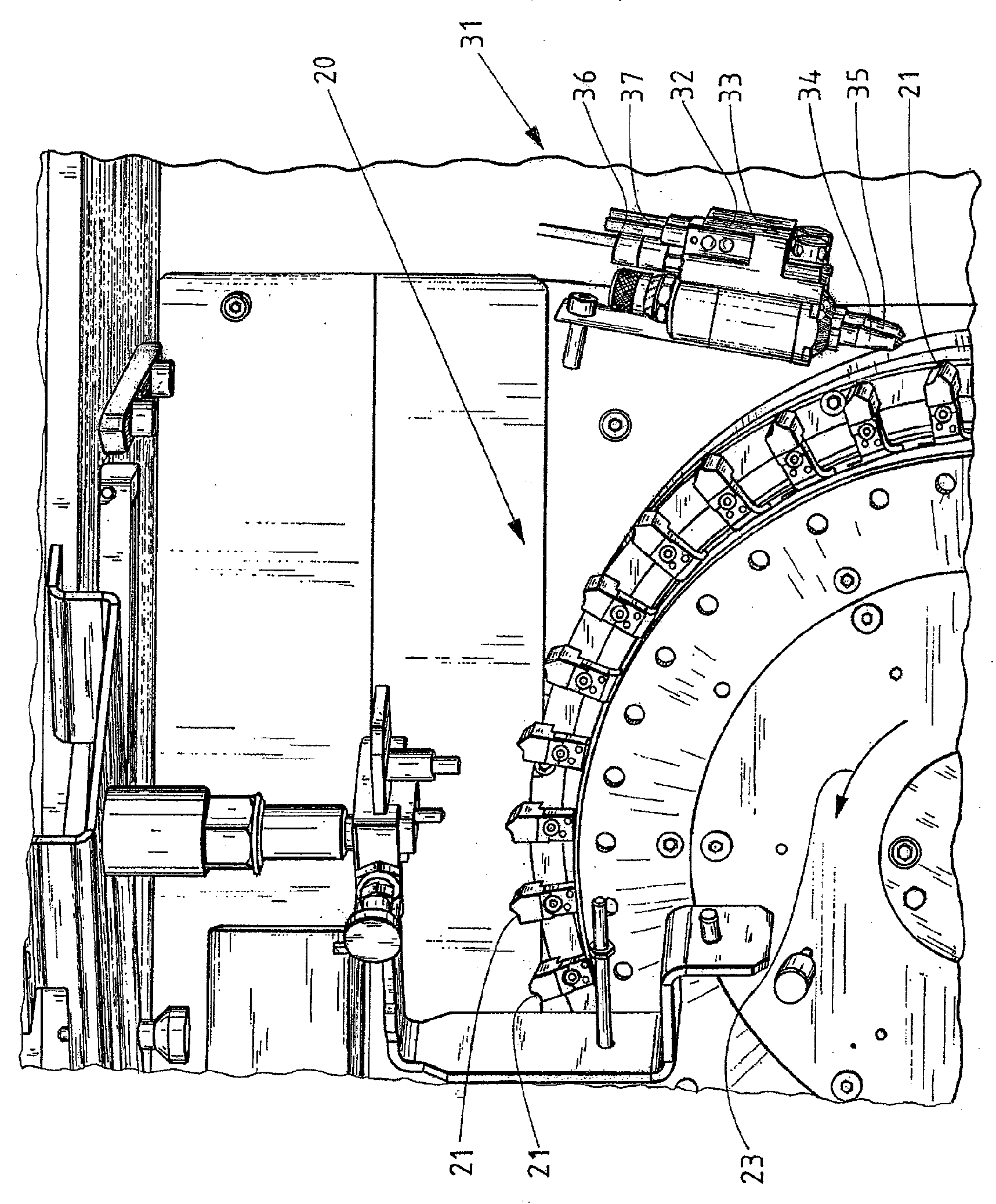

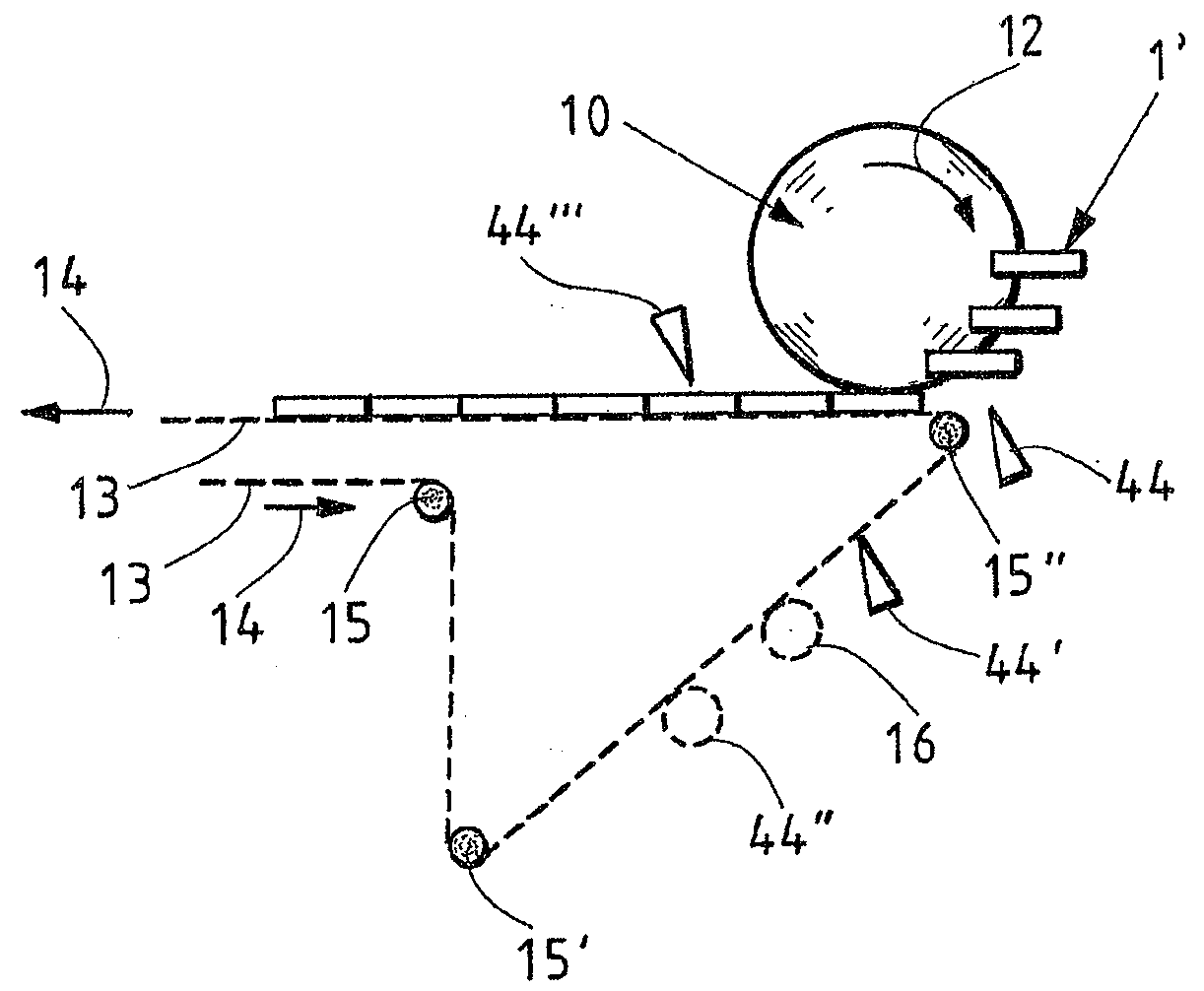

Embodiment Construction

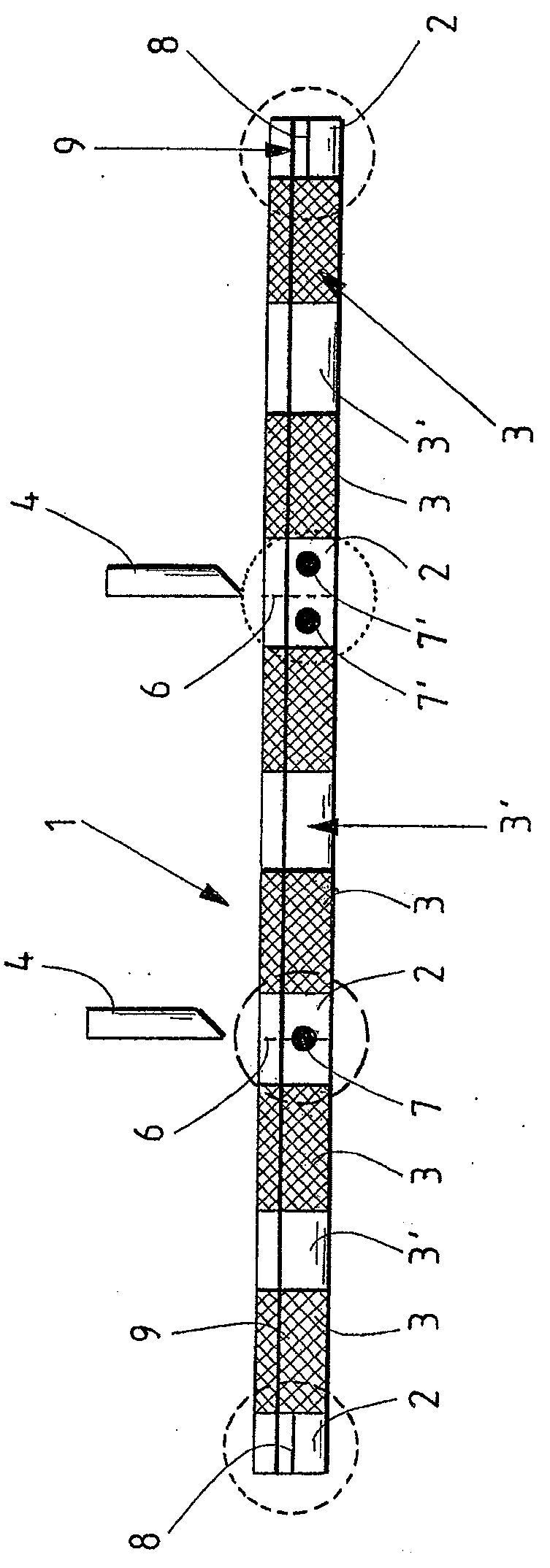

[0036] In the drawings, the same or similar components and / or parts are marked with the same reference numerals, so repeated content will not be repeated.

[0037] exist figure 1A portion of a multi-segment filter rod 1 machined by the invention is shown in . The shown portion of the multi-segment filter rod 1 comprises two multi-segment filter rods 2, 3. The multi-segment filter rod 1 is wrapped with a wrapping paper strip 13 which wraps the groups of segments located therein. 2, 3 tighten. The multi-filter segment is designed as a cutting segment 2 . Cutting lines 6 for subsequent truncating into multi-segmented filter rods are shown.

[0038] In order to ensure adhesion to the covering paper web 13 and to ensure the bonding of the covering paper web 13 to itself, a continuous bead of glue 9 is applied to the covering paper web 13 in its overlapping area with itself. In addition, glue is applied to the multi-segment filter rod 1 without contact. This glue can exist in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com