An injection shaft support connection device

A connection device and shaft support technology, applied in the field of injection molding, can solve the problems of weak structure, short service life, unreliability, etc., and achieve the effect of avoiding the leakage of lubricating oil and the entry of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

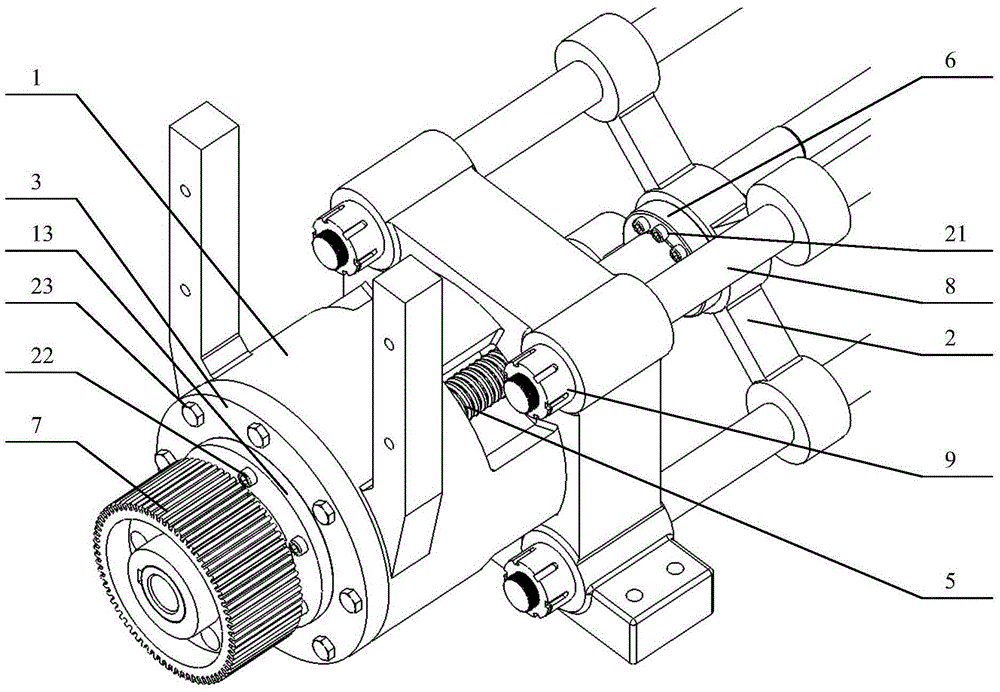

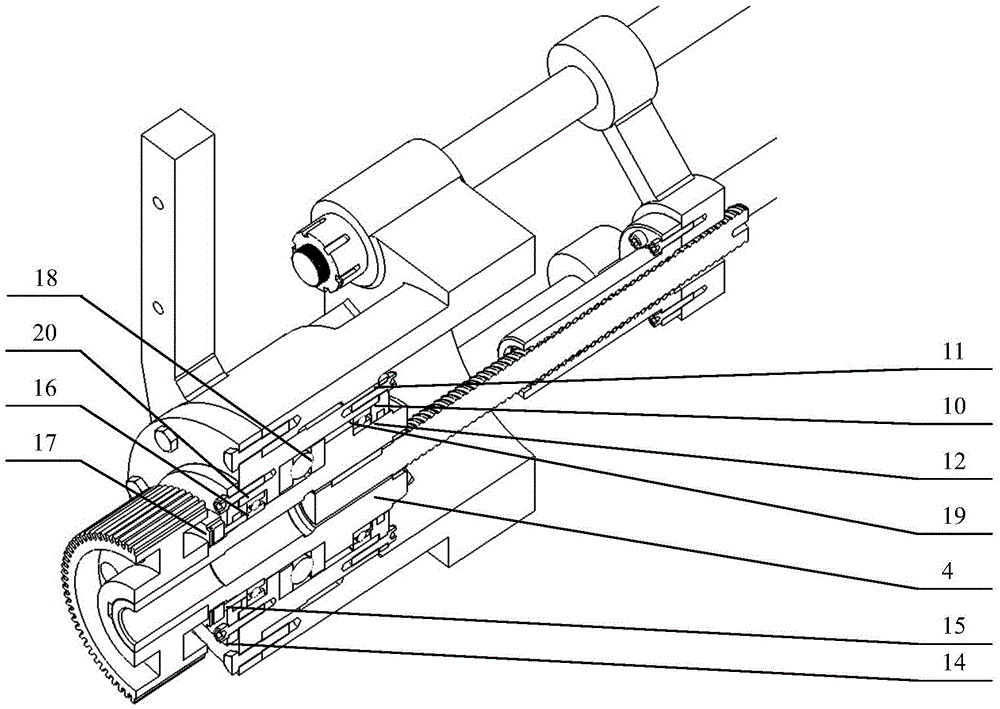

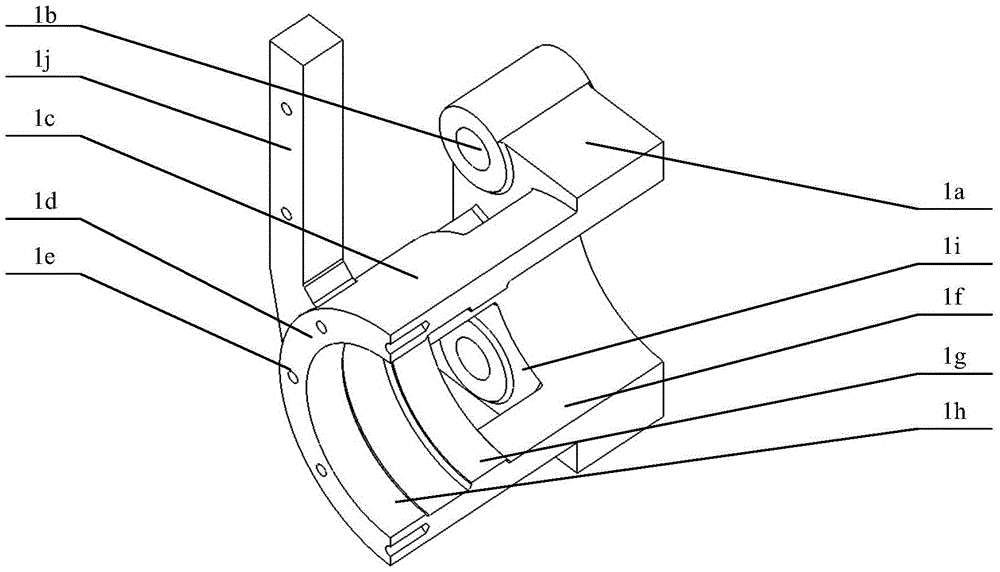

[0021] Such as Figure 1-6 As shown, an injection shaft support connection device includes an injection table 1, the injection table 1 has an inner cavity 1f, a bearing seat 3 is inserted into the inner cavity 1f and is fixedly connected with the injection table 1, and the bearing seat 3 is provided with The injection shaft 4 that is rollingly connected with the bearing seat 3 has an injection shaft center hole 4a, one end of the injection shaft 4 is fixedly connected to the injection pulley 7, and the other end is fixedly connected to the ball screw through the injection shaft center hole 4a 5. The ball screw 5 is screwed to the injection thrust frame 2, and the ball nut 6 is sleeved on the ball screw 5, and the ball nut 6 is fixedly connected to the injection thrust frame 2.

[0022] One end of the injection platform 1 is a square plate 1a, and the other end is a cylinder 1c. The four corners of the square plate 1a are provided with guide rod holes 1b, and the cylinder 1c is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com