Processing method of breathable shoes

A processing method and insole technology, which is applied to footwear, shoe soles, insoles, etc., can solve the problems of elastic airbag failure, affecting the strength of shoe soles or insoles, and failure to automatically restore, so as to achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

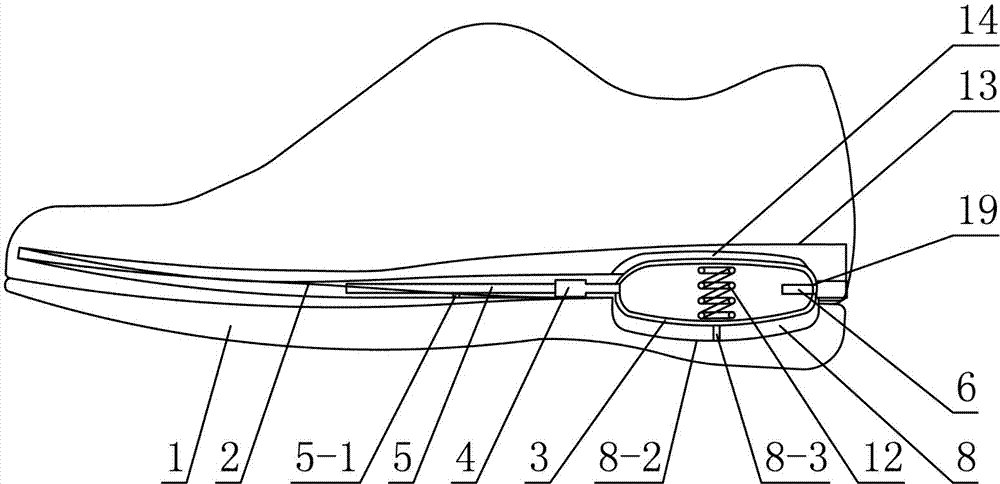

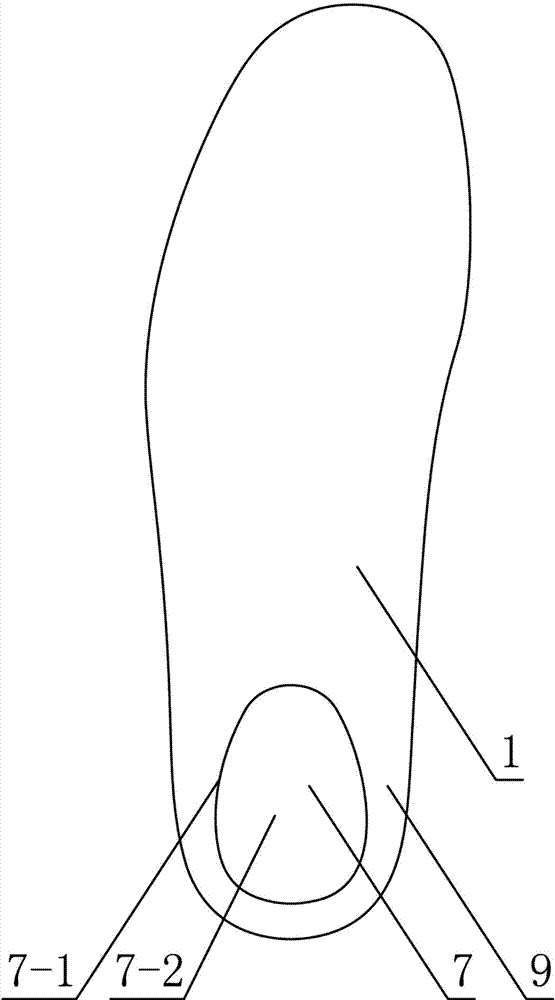

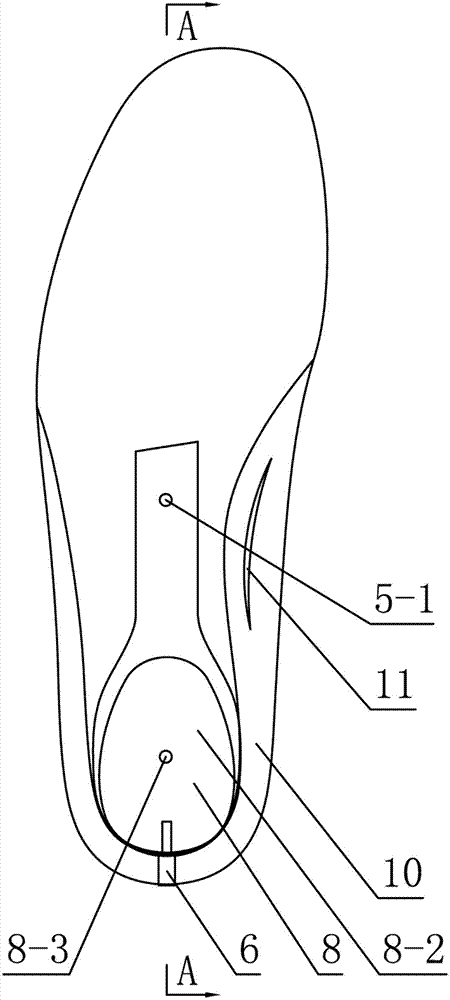

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the processing method of a kind of air-permeable breathing shoes provided by the present invention comprises the preparation method of sole 1 and the preparation method of insole 2, and sole 1 is separately formed by the injection molding of sole 1 mould, and the heel of sole 1 after molding There is a pit 7 at the place, and the preparation steps of the insole 2 include: first, the fabric layer 13 on the upper surface of the insole 2 is initially bonded to the elastic airbag 3 through a silica gel sheet 14, and the front end of the elastic airbag 3 in the above steps is connected with an air intake pipe 5 One end of the air intake pipe 5 communicates with the elastic air bag 3 through a one-way air intake valve 4, the other end of the air intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com