Mechanism and method for stringing and knotting of portable paper bag handle rope

A rope-threading and paper bag technology, which is applied to the field of rope-threading knotting mechanism and rope knotting for hand-held paper bags, can solve the problems of easy damage to the bag body, poor knot consistency, and inconvenient operation, and achieves a good degree of automation. Good consistency and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

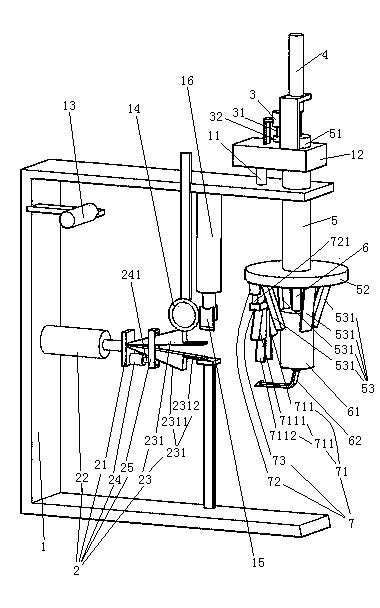

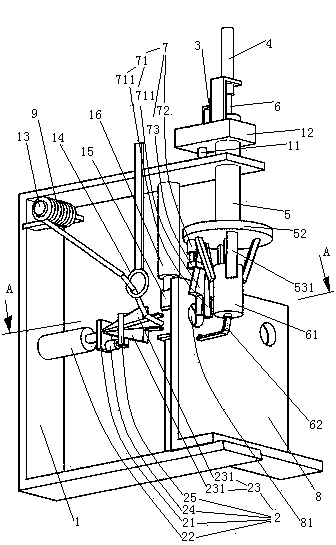

[0032] Embodiment one, see figure 1 , a portable paper bag hand rope threading knot mechanism, including a frame 1. The frame 1 is provided with a rope-threading manipulator 2 , a first actuator 11 , a rope roll installation frame 13 , a guide ring 14 , a cutter 15 and a lifting seat 12 driven by the first actuator 11 . Cutter 15 is connected on the frame 1 by cutter drive cylinder 16.

[0033]The rope-threading manipulator 2 includes a clip mount 21 and a clip translation cylinder 22 that connects the clip mount 21 to the frame 1 . The clip mounting seat 21 is fixedly connected with a rope-threading clip 23 and a rope-threading clip closing the cylinder 24. The threading clip 23 includes a pair of threading clips 231 . The rope clip 231 is an elastic steel sheet. The rope-threading clips 231 are connected together in a "eight" shape and are in a horizontal state. The rope-threading clip 231 is provided with a rope-threading clip closing control section 2311 and a rope-th...

Embodiment 2

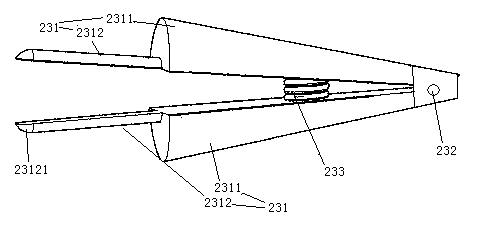

[0049] Embodiment two, the difference with embodiment one is: see image 3 , the rope-threading clips 231 are hinged together through hinge shafts 232 . The outer surface of the rope clip closing control section 2311 is a tapered surface. An expansion spring 233 is arranged between the pair of rope-threading clips 231 . The free end face 23121 of chuck is spherical. The pair of stringing clips 231 are kept apart by expanding the spring 233 . The structural form of the rope-winding clip that constitutes the rope-winding manipulator is the same as the structural form of the rope-threading clip.

[0050] see Figure 4 The rope withdrawal structure 53 includes a rope withdrawal ring 532 sleeved on the rope winding section 61 and a connecting rod 533 for suspending the rope withdrawal ring 532 on the turntable 52 . There is an adsorption channel 63 extending in the vertical direction in the handle 6 . The inlet 631 of the suction channel is arranged on the side of the rope-wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com