Buffering mechanism and automobile comprising buffering mechanism

A buffer mechanism and buffer block technology, which is applied to vehicle components, elastic suspensions, suspensions, etc., can solve the problems of fatigue cracking of the buffer block seat, large load bearing, and instability of the buffer block, and achieve both comfort requirements and limitations Position requirements, stable cushioning performance, and reduced stiffness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

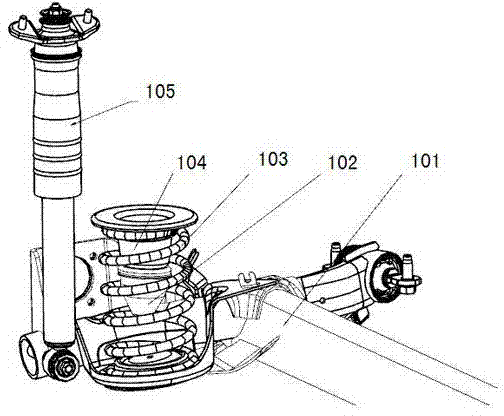

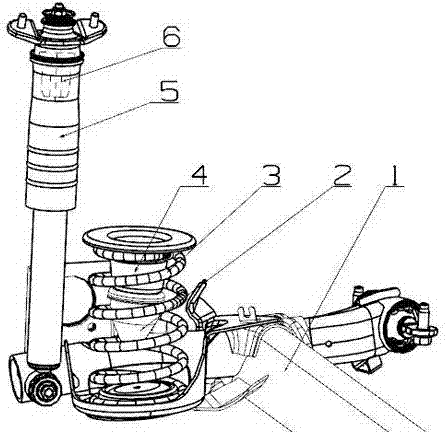

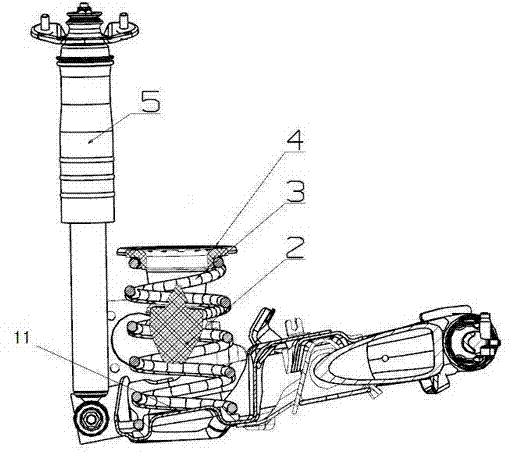

[0025] Figure 2 to Figure 4 The reference numbers in are: torsion beam assembly 1; first impact member 11; buffer block 2; spring 3; bracket 4; shock absorber assembly 5; piston rod 51; second impact member 52; .

[0026] The purpose of the present invention is to provide a rear suspension suitable for torsion beams, which can effectively meet the comfort requirements of the suspension buffer under the premise of ensuring that the suspension stroke of the automobile suspension is met, so that the automobile can obtain excellent performance. A buffer mechanism that meets the requirements of the fatigue life of the buffer component.

[0027] Such as Figure 2 to Figure 4 As shown, a buffer mechanism includes a torsion beam assembly 1, a buffer assembly, a spring 3 and a shock absorber assembly 5, and the spring 3 and the shock absorber assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com