A needle-free coaxial electrospinning device and spinning method

A coaxial electrospinning, needle-free technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problem of no coaxial electrospinning device, and achieve continuous and large-scale The effect of producing, avoiding easy clogging, and avoiding needle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

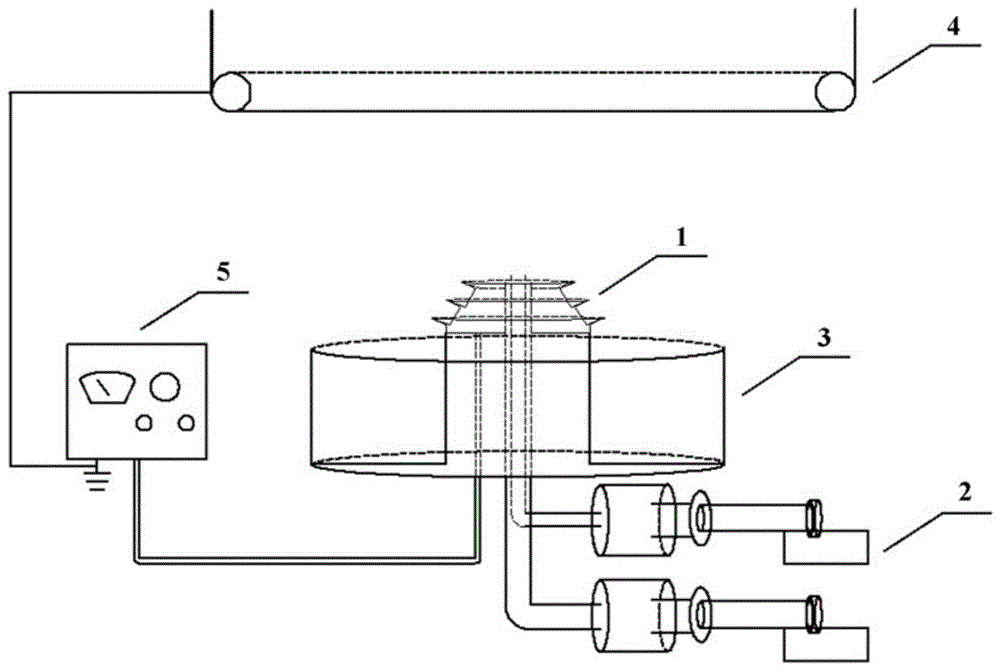

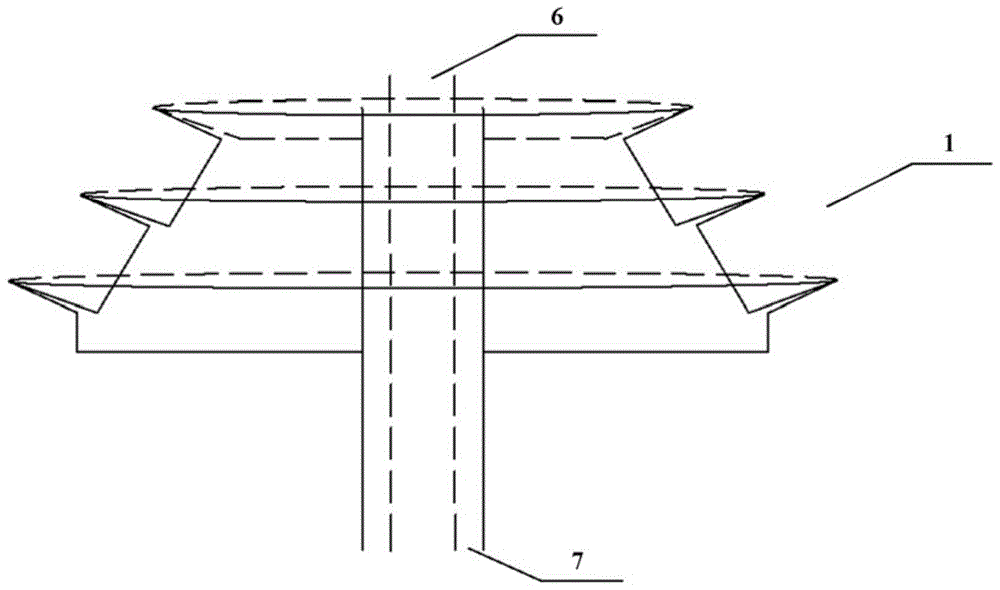

[0031] use figure 1 The shown needle-free coaxial electrospinning device performs coaxial electrospinning, the core layer solution uses a polyacrylonitrile (PAN) solution with a mass concentration of 8%, and the shell layer solution uses a 12% polyurethane (PU) solution. The output end of the liquid storage container with the core layer solution is placed in the middle cylindrical hollow outer tube 7 of the ladder-shaped needle-free nozzle 1, and the output end of the liquid storage container with the shell solution is placed in the middle of the ladder-shaped needle-free nozzle 1 In the cylindrical hollow inner tube 6, the core layer spinning solution and the shell layer spinning solution flow down from the top layer of the ladder-shaped needle-free nozzle 1 along the surface of the ladder-shaped needle-free nozzle under the action of their respective propellers, so that the ladder Each edge of the needle-free nozzle is covered with two layers of spinning solution. At this t...

Embodiment 2

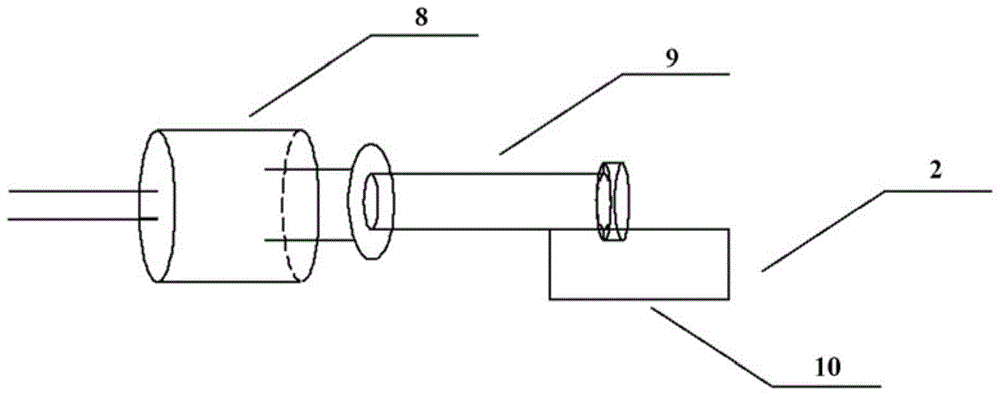

[0033] Such as figure 1 and figure 2 As shown, a needle-free coaxial electrospinning device includes five parts: a stepped needle-free spinneret 1, a liquid supply system 2, a solution recovery tank 3, a receiving device 4, and a high-voltage electrostatic generator 5. Its characteristics That is, the receiving device 4 is provided above the stepped needle-free spinneret 1, and a solution recovery tank 3 is placed at the bottom of the stepped needle-free spinneret 1. Below the needle spinneret 1, there is a terminal connected to the high-voltage generator 5; the center of the stepped needle-free spinneret 1 is a hollow place, and the output end of the liquid supply system 2 is placed in the The hollow part of the stepped needle-free spinneret 1; the stepped needle-free spinneret 1 is circular and stepped, with a three-layer structure, and the diameter from the top layer to the bottom layer gradually increases, and each layer The inner side of the edge is 45° to the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com