A composite bridge plug and its central tube

A technology of center pipe and composite bridge, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc., which can solve problems such as difficult drilling and removal of rubber tubes, failure to lose hands, and difficulty in cutting shear pins, etc., to achieve Guarantee reliability and ensure reliable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

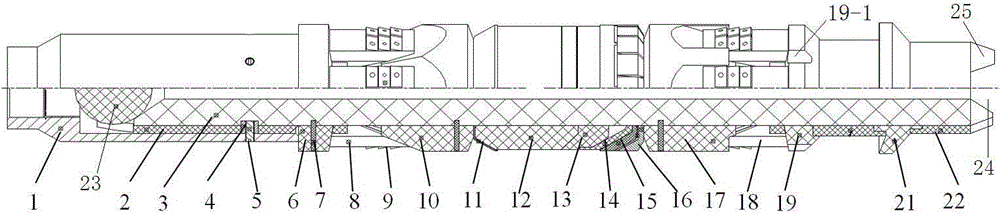

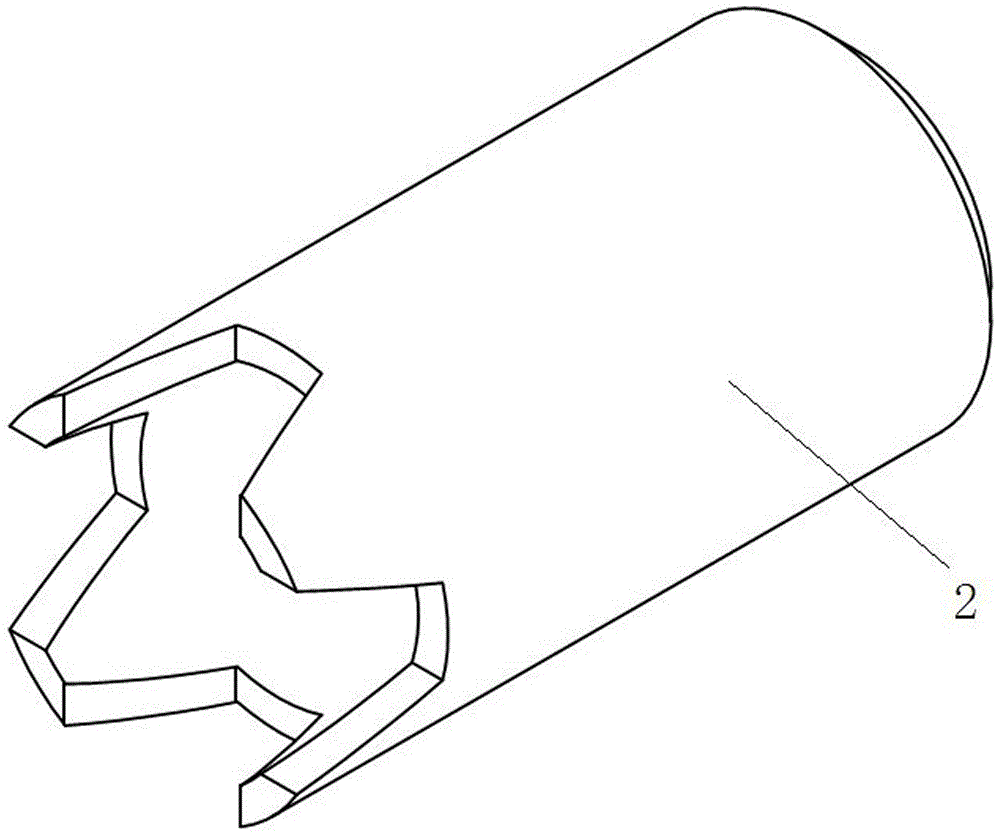

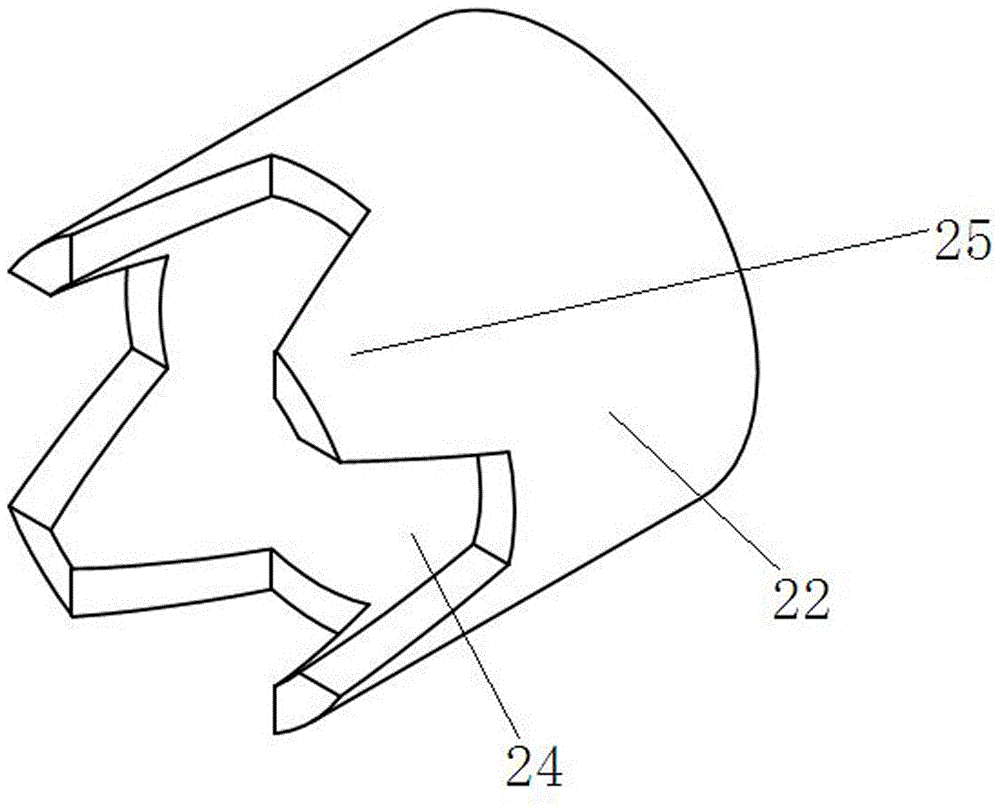

[0026] Embodiment 1 of a composite bridge plug is as Figure 1~6 As shown: including the central tube 3 whose axis extends in the up-down direction, the outer peripheral surface of the tube of the central tube is provided with an anti-rotation outer structure, and the anti-rotation outer structure is a square convex key 3 that is consistent with the extension square of the central tube in the length direction -1, on the anti-rotation outer structure from top to bottom, the anti-rotation sleeve is equipped with a setting pressure ring 6, a sealing assembly and a stop ring 19, and the sealing assembly includes an upper slip 8 and an upper cone arranged in sequence. Body 10, upper retainer 11, rubber sleeve, lower retainer, lower cone 17 and lower slip 18, setting pressure ring, stop ring, upper slip, upper cone, upper retainer, rubber sleeve, lower The retainer, the lower cone and the lower slips are fitted on the outer structure of the central tube through their respective anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com