Traveling truck

A technology of driving platform and trolley, which is applied in the direction of electric vehicles, vehicle parts, welding equipment, etc., can solve the problem of adjustment of difficult positions for operators, and achieve good welding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

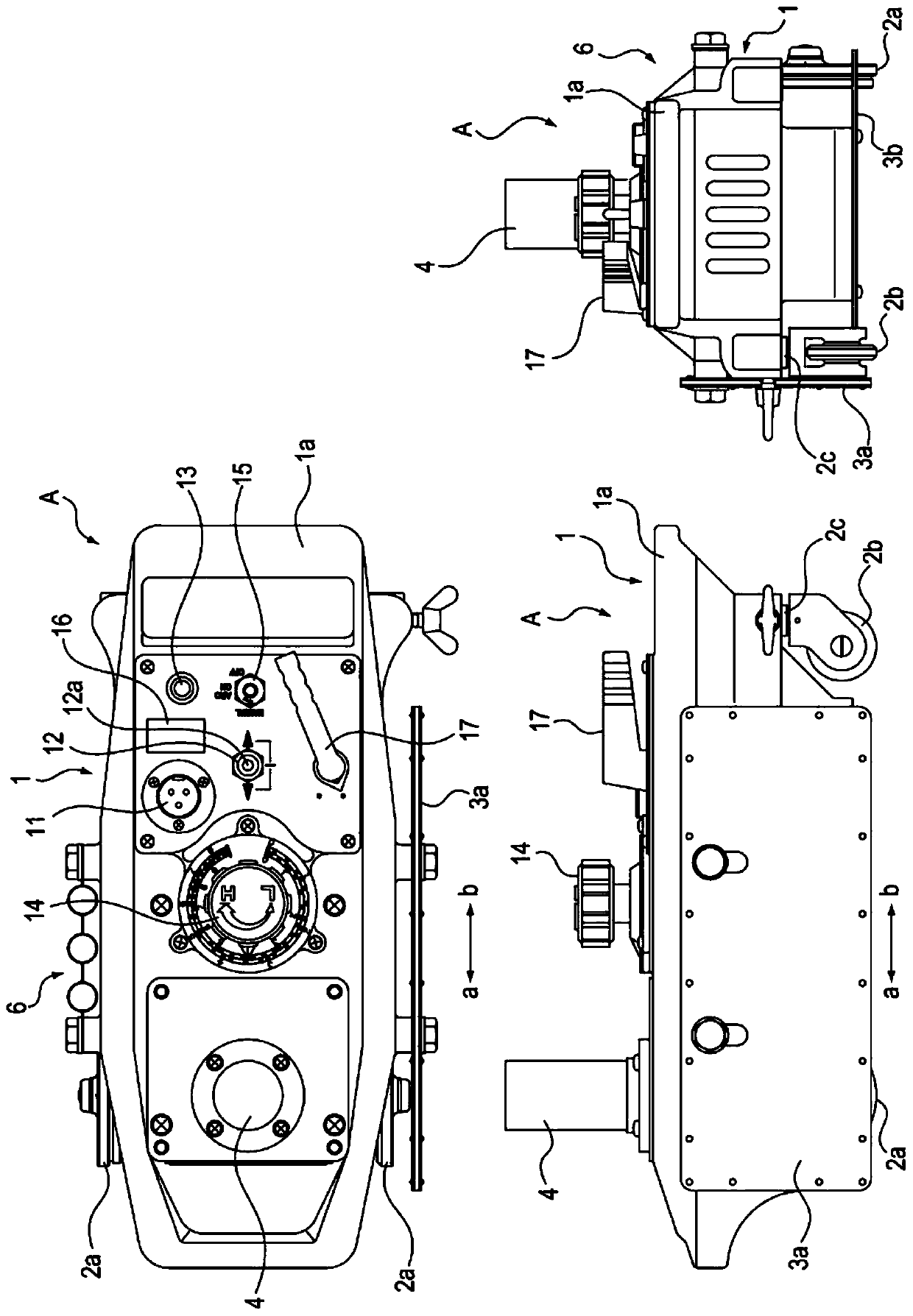

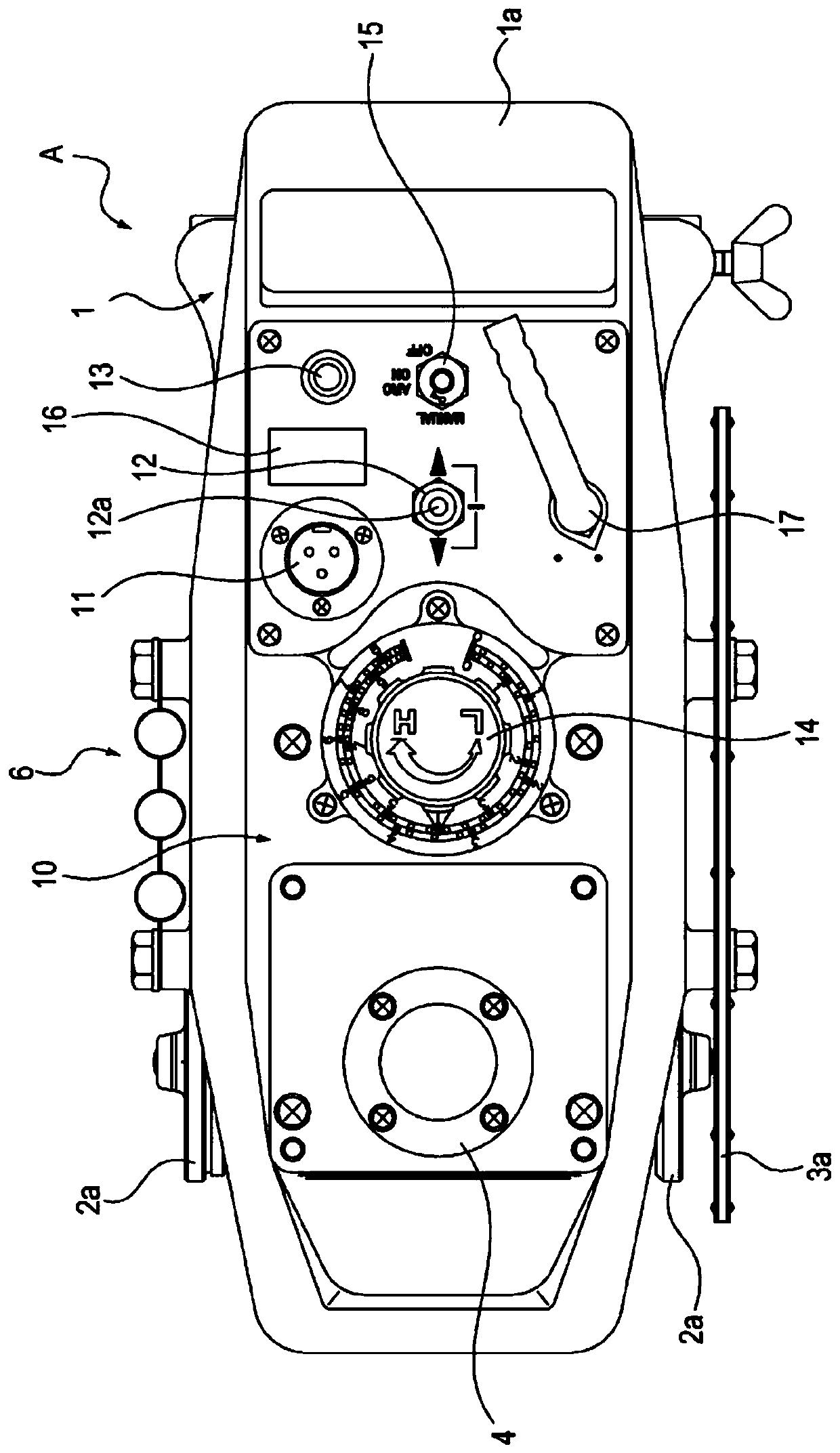

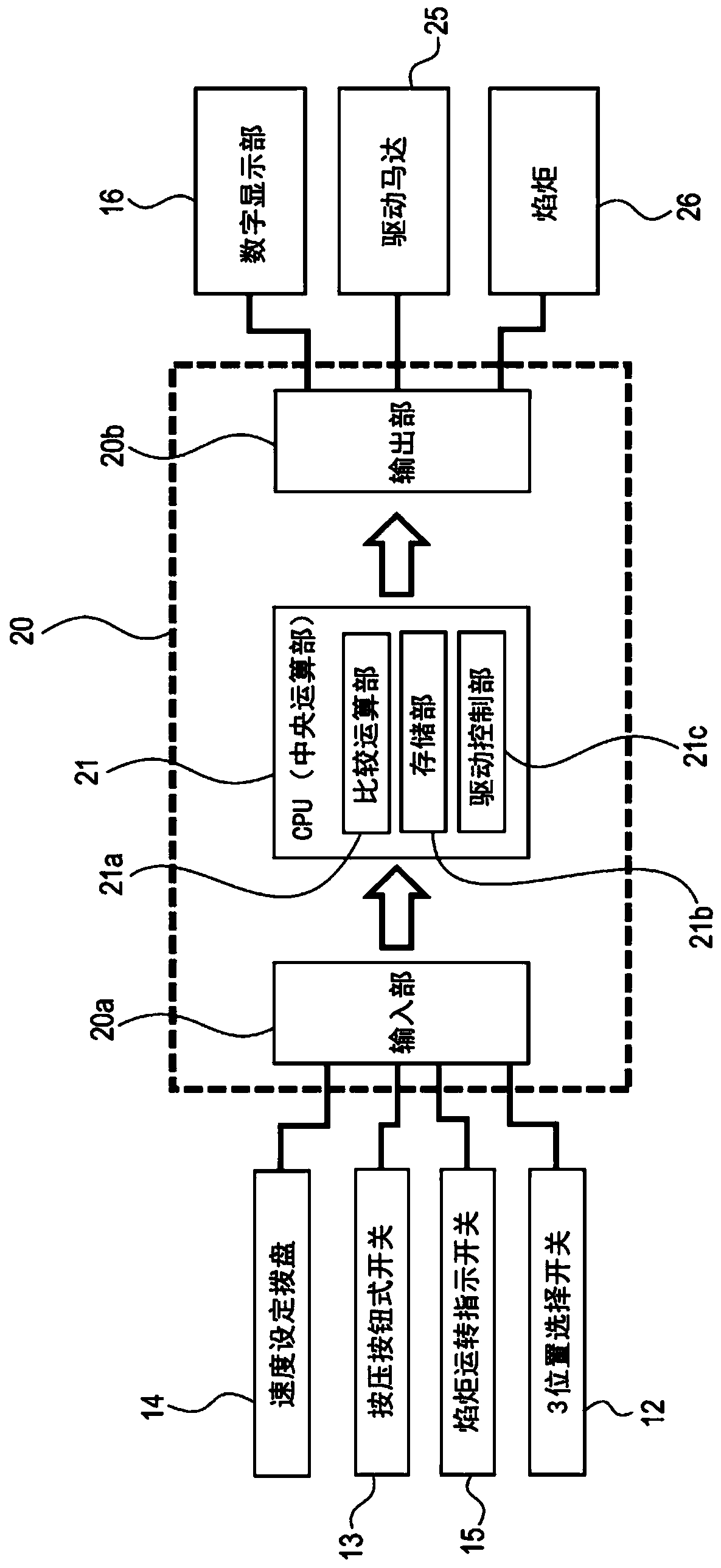

[0034] Hereinafter, the traveling vehicle of the present invention will be described. The present invention is a traveling trolley equipped with a torch such as a cutting torch or a welding torch, and used when cutting or welding a workpiece represented by a steel plate (hereinafter referred to as "steel plate"). In particular, it is configured to be able to reliably perform the process of starting or terminating cutting from the end face of the workpiece, piercing the workpiece and then continuously cutting from the piercing point, or starting welding. when processing, or when terminating welding.

[0035] A torch for gas cutting, a torch for plasma cutting, and the like can be selectively adopted as the torch for cutting the steel plate mounted on the traveling carriage. In the gas cutting torch, it is connected to the fuel gas supply device and the oxygen supply device through a plurality of hoses. In the plasma torch, it is connected to the power supply through a double-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com