Well completion sand prevention process and sand prevention strings thereof

A sand control pipe and process technology, applied in drilling pipes, casings, drilling equipment, etc., can solve the problems of single treatment measures, affecting the operation progress, and low one-time success rate, so as to meet the requirements of sand control technology, reduce operation risks, and solve the problems of sand control. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

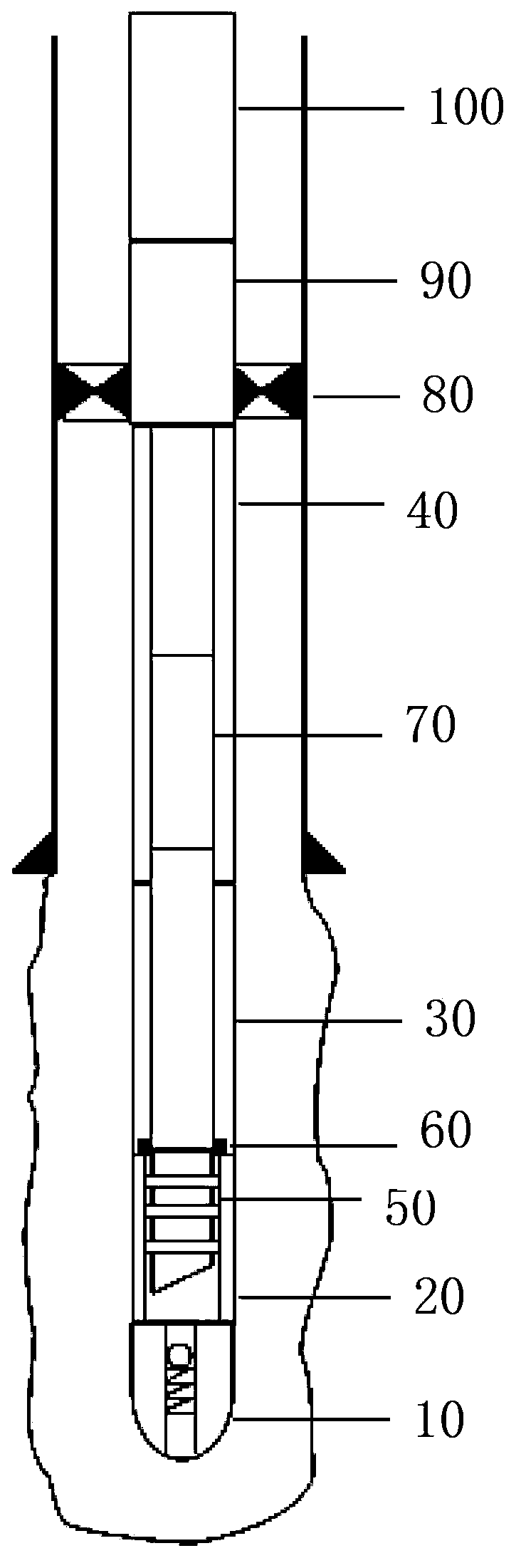

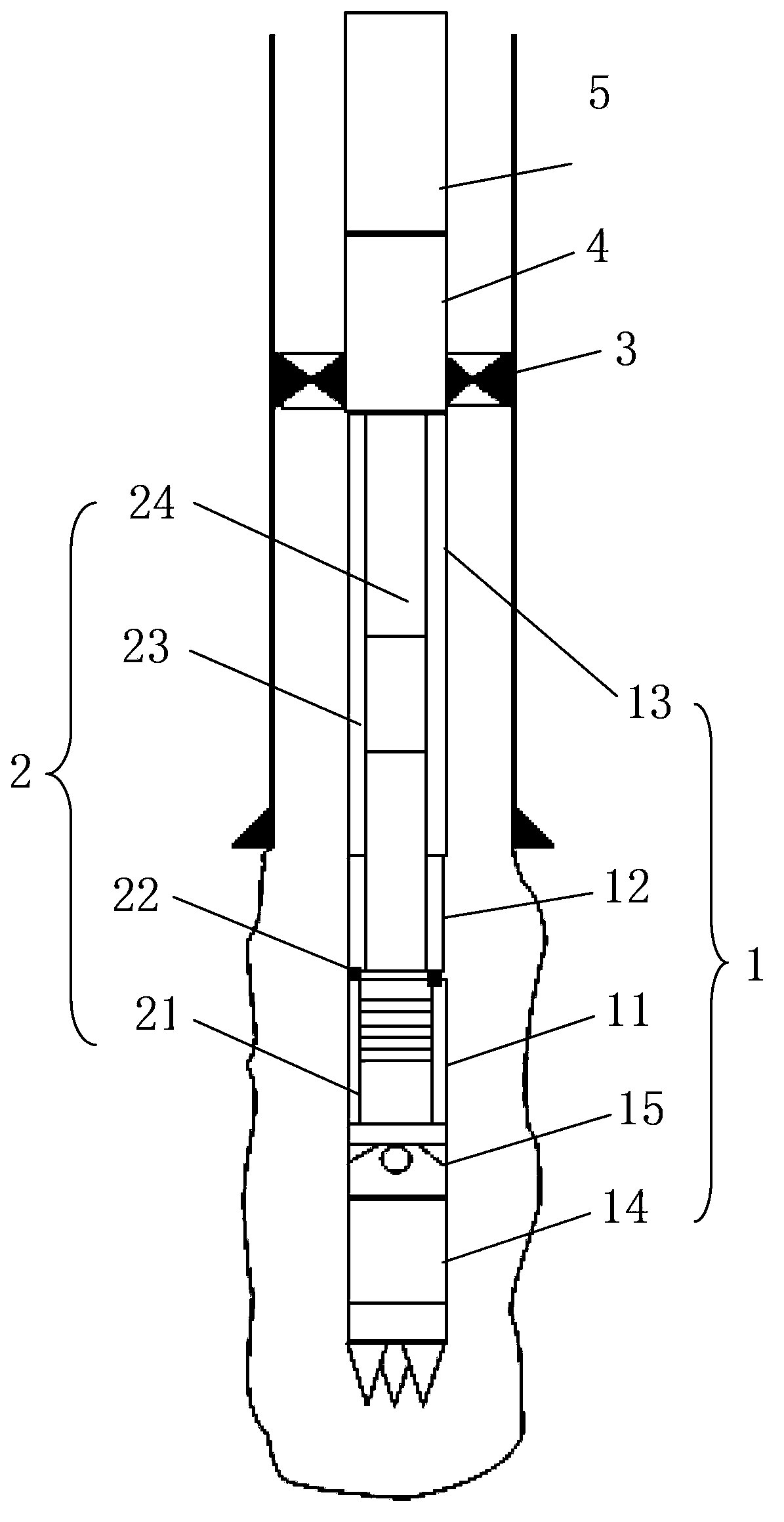

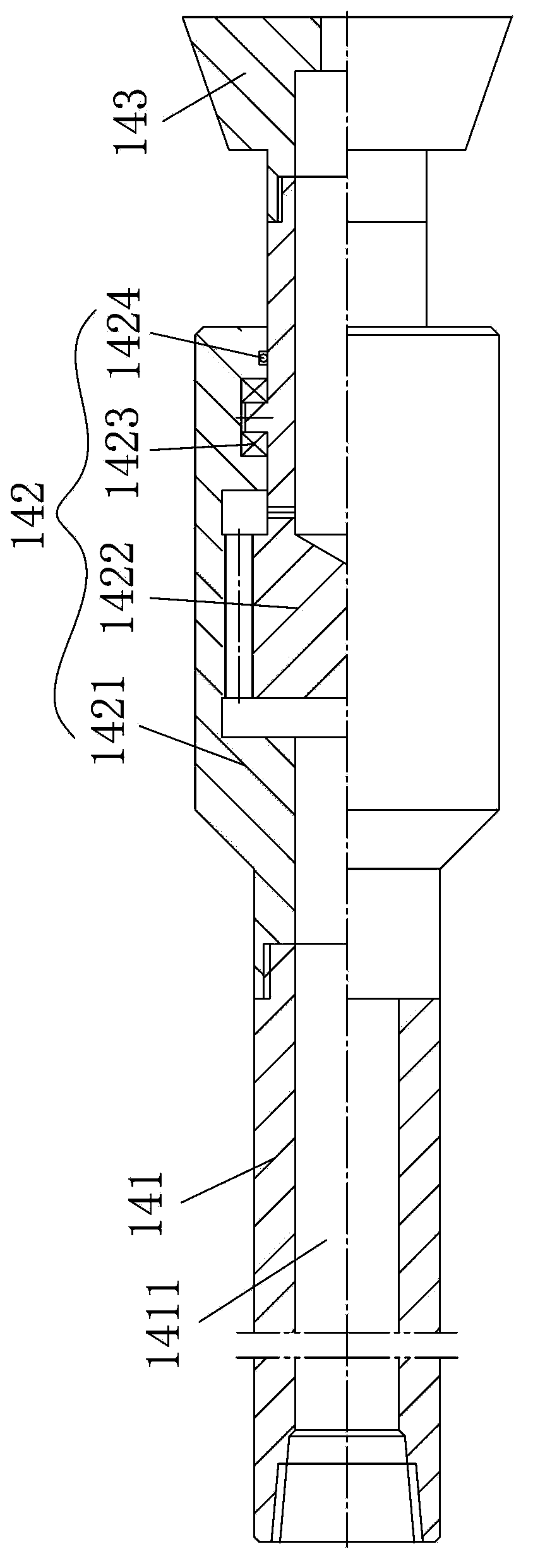

[0084] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0085] see figure 2 , figure 2 It is a structural schematic diagram of a sand control pipe string according to an embodiment of the present invention. The sand control pipe string used in the sand control process of well completion of the present invention includes an outer pipe string 1 and an inner pipe string 2, the inner pipe string 2 is located in the lumen of the outer pipe string 1 and is connected to the outer pipe string 1 Coaxially arranged, the inner pipe string 2 includes an insertion sealing cylinder 21, a positioning head 22 and a flushing tube 23 connected sequentially from bottom to top, and the outer pipe string 1 includes a sealing cylinder 11 connected sequentially from bottom to top , a screen pipe 12 and a blind pipe 13, the tops of the blind pipe 13 and the flushing pipe 23 are respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com