Refrigerant filling component for air conditioner and refrigerant filling method

An air conditioner and refrigerant technology, applied in the direction of refrigeration components, applications, refrigerators, etc., can solve problems such as errors and air conditioner system performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

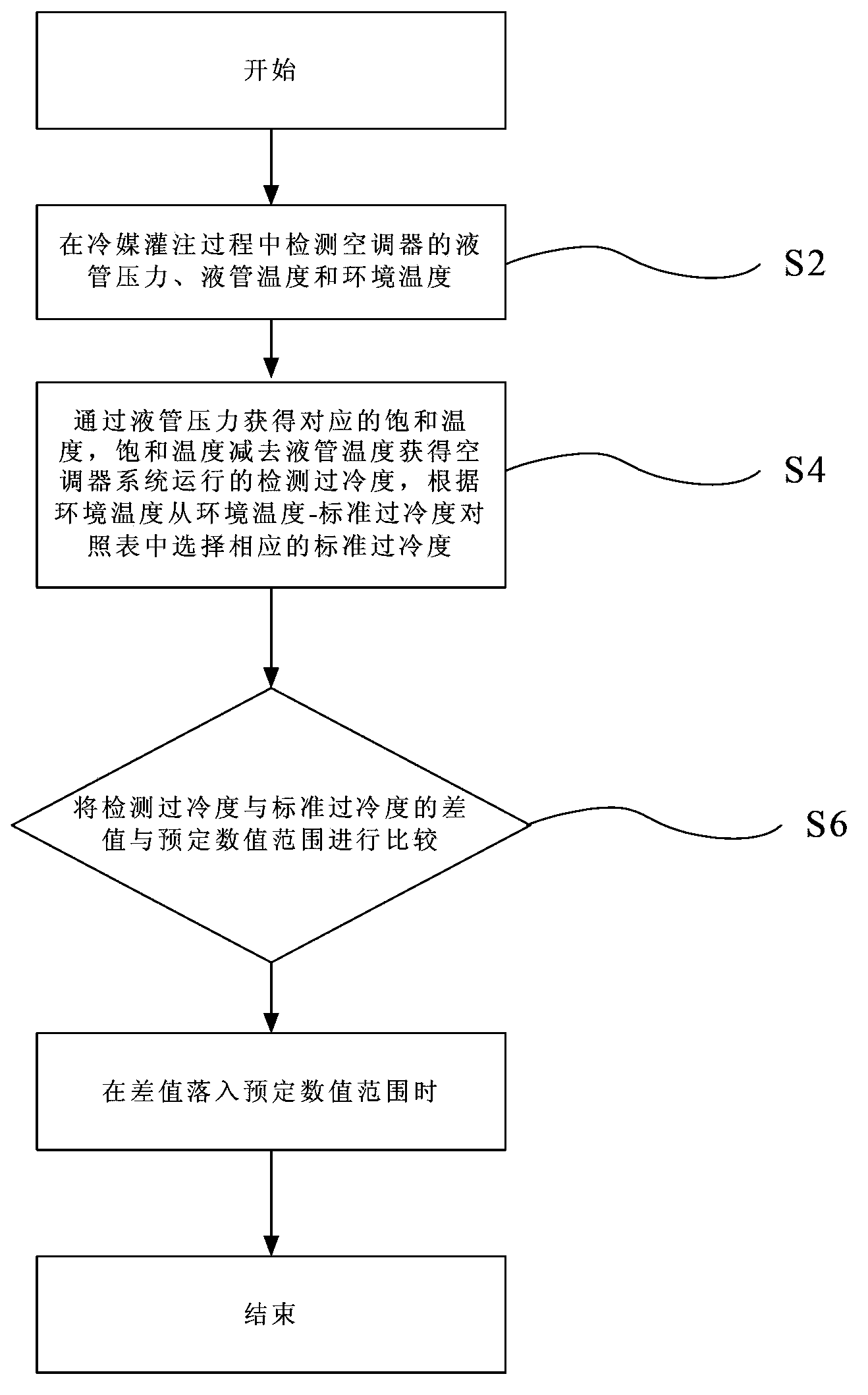

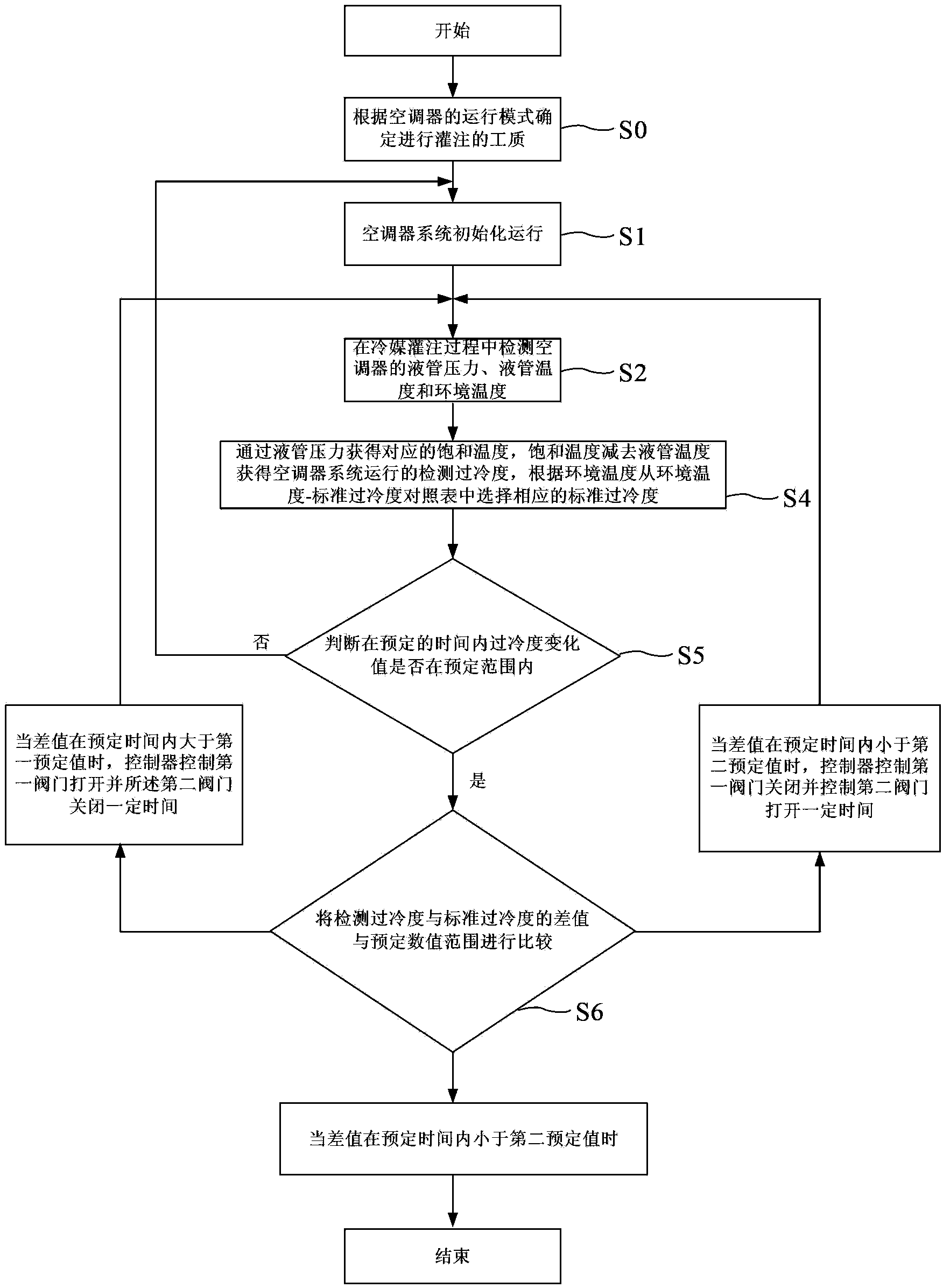

[0022] Such as figure 2 As shown, the present invention provides the first embodiment of the refrigerant injection method, and the refrigerant injection method in this embodiment includes the following steps:

[0023] S2: Detect the liquid pipe pressure, liquid pipe temperature and ambient temperature of the air conditioner during the refrigerant filling process;

[0024] S4: Obtain the corresponding saturation temperature through the liquid pipe pressure, subtract the liquid pipe temperature from the saturation temperature to obtain the detected subcooling degree of the air conditioner system, and select the corresponding standard subcooling degree from the ambient temperature-standard subcooling degree comparison table according to the ambient temperature Spend;

[0025] S6: Comparing the difference between the detected subcooling degree and the standard subcooling degree with a predetermined value range, and stopping refrigerant injection when the difference falls within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com