Nicotine filter unit for cigarettes, filling granules of nicotine filter unit and method for manufacturing filling granules

A filter device and particle filling technology, which is applied in tobacco, tobacco pipes, applications, etc., can solve the problems of low filtration rate and harm to the health of smokers, and achieve the goal of reducing harm, increasing utilization value and market benefits, and promoting the development of marine economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method for filling particles in a cigarette nicotine filter device, comprising the following steps:

[0024] Step S10: Squeeze the juice of Enteromorpha to obtain Enteromorpha residue;

[0025] Step S20: drying the Enteromorpha slag liquid to obtain dried Enteromorpha slag;

[0026] Step S30: pulverizing Enteromorpha slag into granules;

[0027] Step S40: Sterilize the pulverized granular Enteromorpha slag to obtain the filled particles.

[0028] The filling particles prepared by the preparation method of the filling particles in the cigarette nicotine filtering device of this embodiment can filter nicotine, tar, tripropylene glycol methyl ether and other nicotine produced during the burning of cigarettes, and reduce the amount of smoke inhaled by smokers. Alkaline content, reducing the harm to the body caused by people smoking cigarettes.

[0029] In this embodiment, optionally, in order to obtain clean Enteromorpha without sand and stones, step S05 is...

Embodiment 2

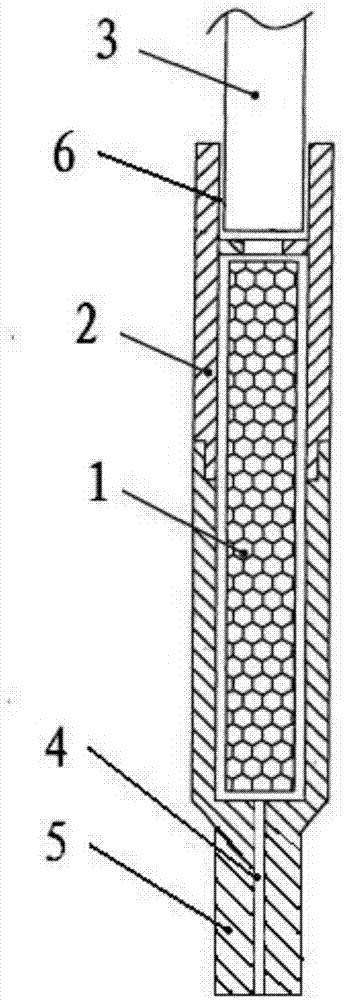

[0038] see figure 1 , this embodiment provides a cigarette nicotine filtering device, including a filter cartridge 2, one end of the filter cartridge 2 is provided with a suction nozzle 5, and the other end is provided with a smoke insertion part 6, and the inside of the filter cartridge 2 is filled with cavity, the suction nozzle 5 is provided with a smoke channel 4 communicating with the filling cavity, and the smoke insert 6 is also communicating with the filling cavity; the filling cavity is filled with the Preparation method Prepared filled particles 1 .

[0039] When in use, insert the cigarette 3 into the cigarette inserting portion 6 and inhale through the mouthpiece 5 .

[0040] The cigarette nicotine filtering device of this embodiment can filter nicotine, tar, tripropylene glycol methyl ether and other nicotine produced during the burning of cigarettes, reduce the amount of nicotine inhaled by smokers, and reduce the impact on the body of people smoking cigarettes....

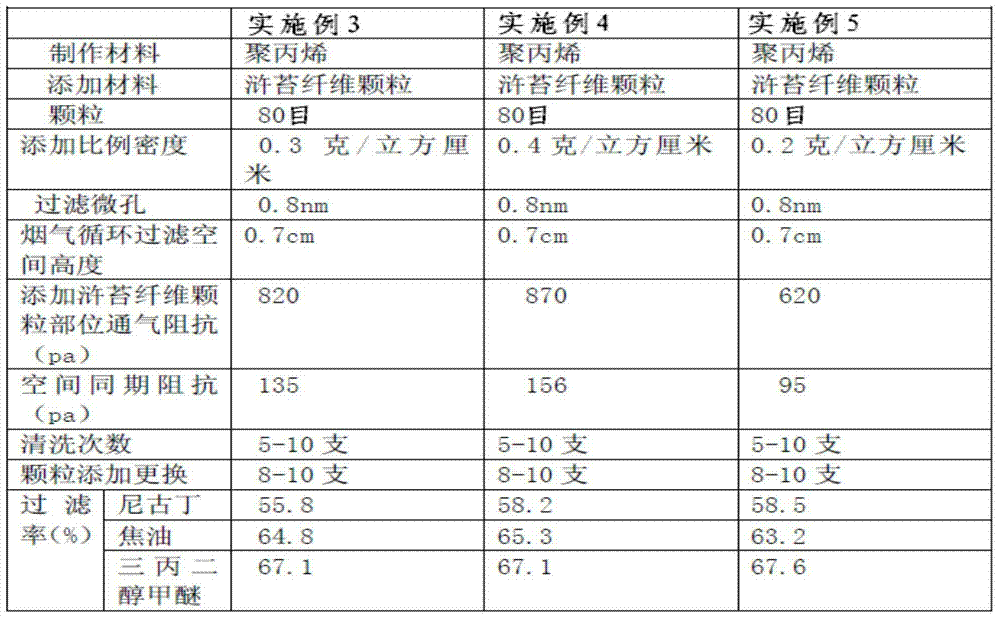

Embodiment 3

[0042] This embodiment provides a preparation method for filling particles in a cigarette nicotine filter device, comprising the following steps:

[0043] Step 1: Select Enteromorpha: Select fresh Enteromorpha that has been used for ≤2 days after salvage, and the natural temperature after salvage is ≤37°C.

[0044] Step 2: Remove sand and stones by 80kpa high-pressure water washing for 15 minutes.

[0045] Step 3: squeeze the juice from the washed Enteromorpha to obtain Enteromorpha slag.

[0046] Step 4: Use hot air with a temperature of 60°C to carry out hot air circulation intermittent drying on the Enteromorpha slag liquid, specifically: pass hot air to the Enteromorpha slag liquid for 10 minutes to dry, stop the hot air for 10 minutes, and then pass hot air to dry for 10 minutes , into the hot air and stop the hot air circulation for 8 hours.

[0047] The fifth step: pulverize the enteromorpha slag dried in the fourth step to a particle size of 10 mesh.

[0048] Step 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com