High-intensity water channel core of crankcase body and high-intensity water channel core fixed mould of crankcase body

A crankcase body and high-strength technology, applied in cores, casting molding equipment, casting molds, etc., can solve problems such as easy deformation, increased cost, and reduced casting pass rate, so as to achieve the goal of not easily deformed or broken, and prolong the service life , Ensure that the size of the water channel is qualified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

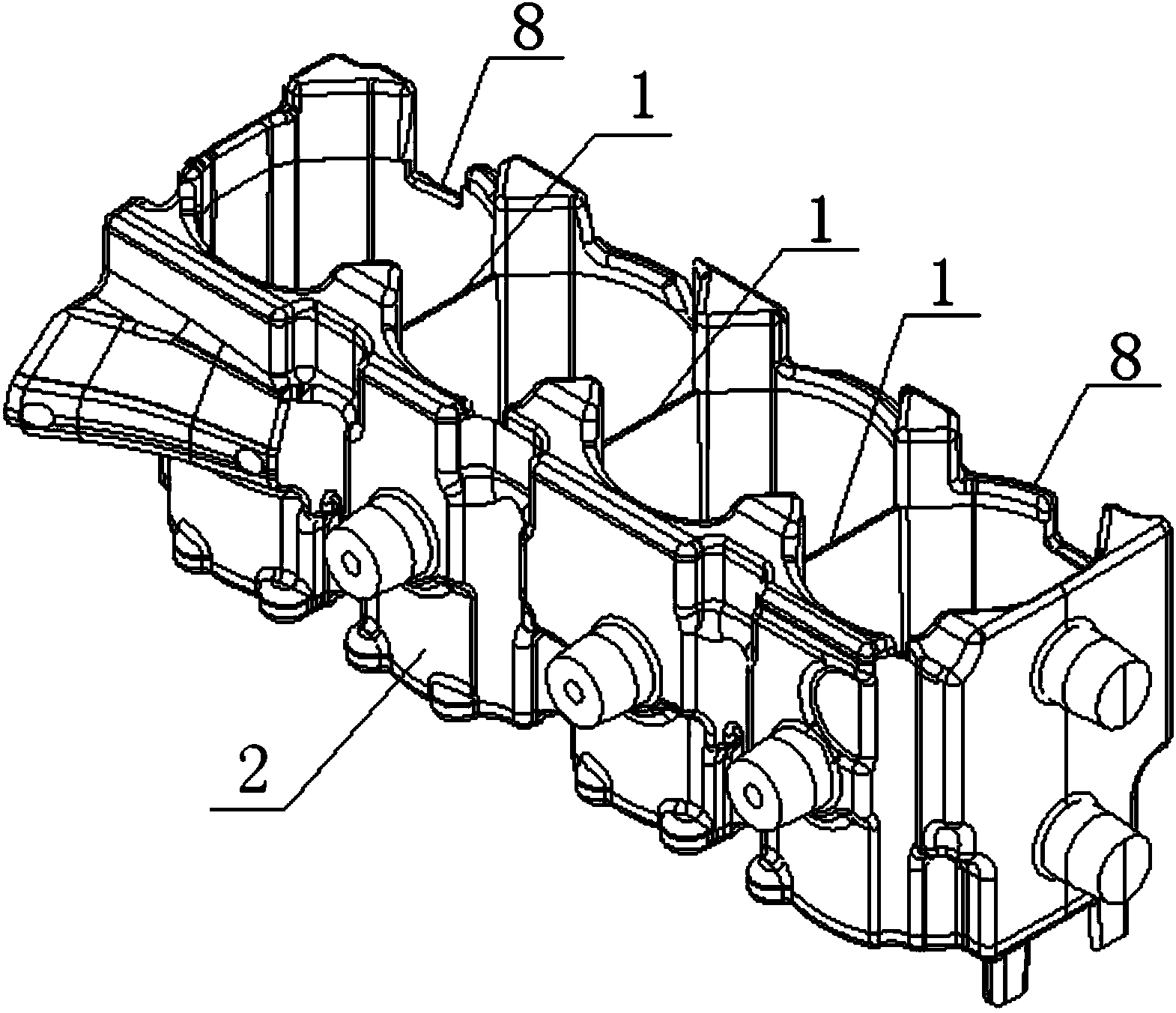

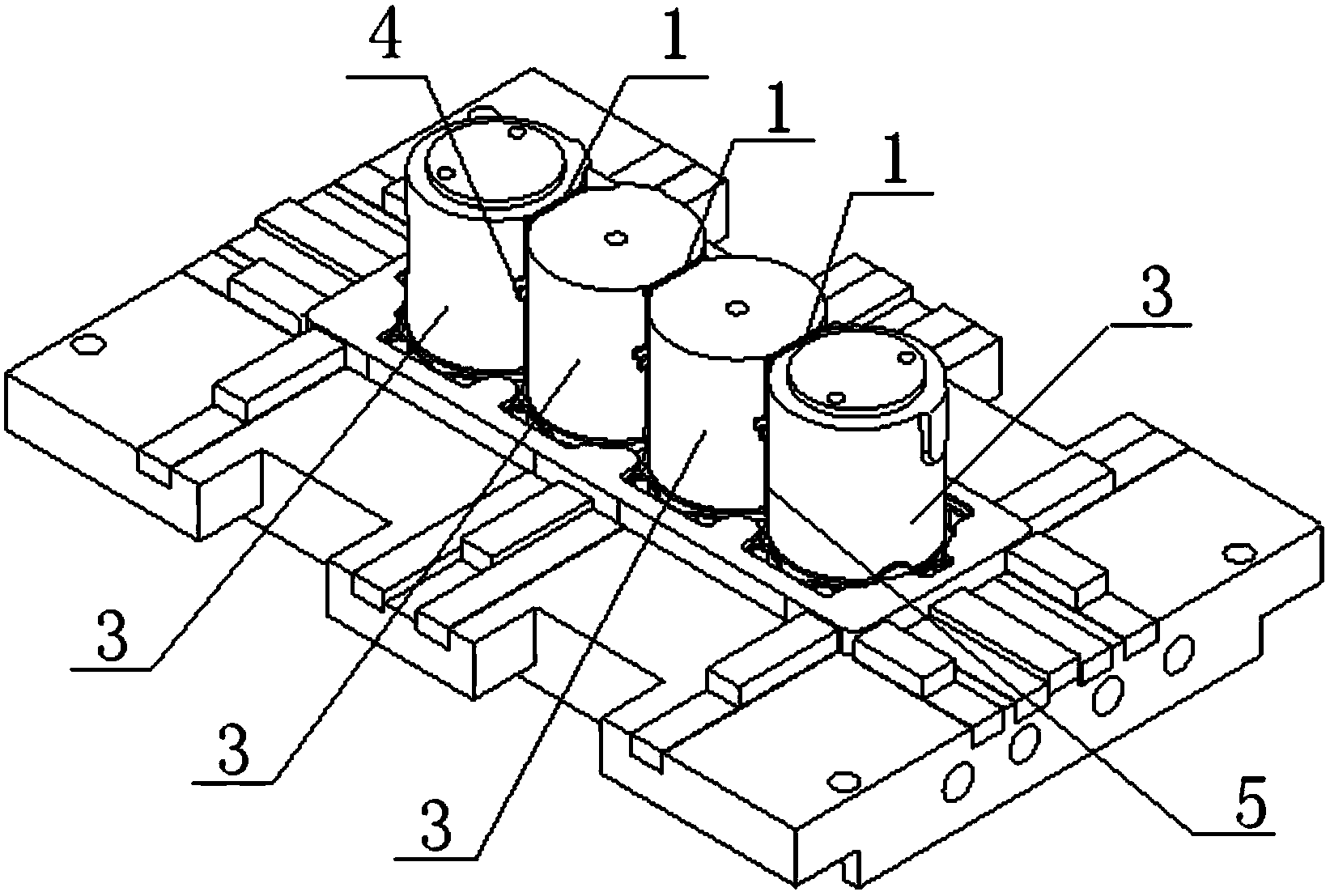

[0022] Such as figure 1 As shown, the high-strength waterway core 2 of the crankcase body of the present invention includes four vertical hollow cylindrical units 8 connected side by side, and two adjacent hollow cylindrical units 8 are provided with parallel to the vertical direction, the left and right sides of the reinforced support plate 1 are placed in the connecting body between two adjacent hollow cylindrical units 8, and there are three reinforced support plates 1, all of which are rectangular steel plates. Using 1.5mm thick Q235 steel plate, formed by stamping parts.

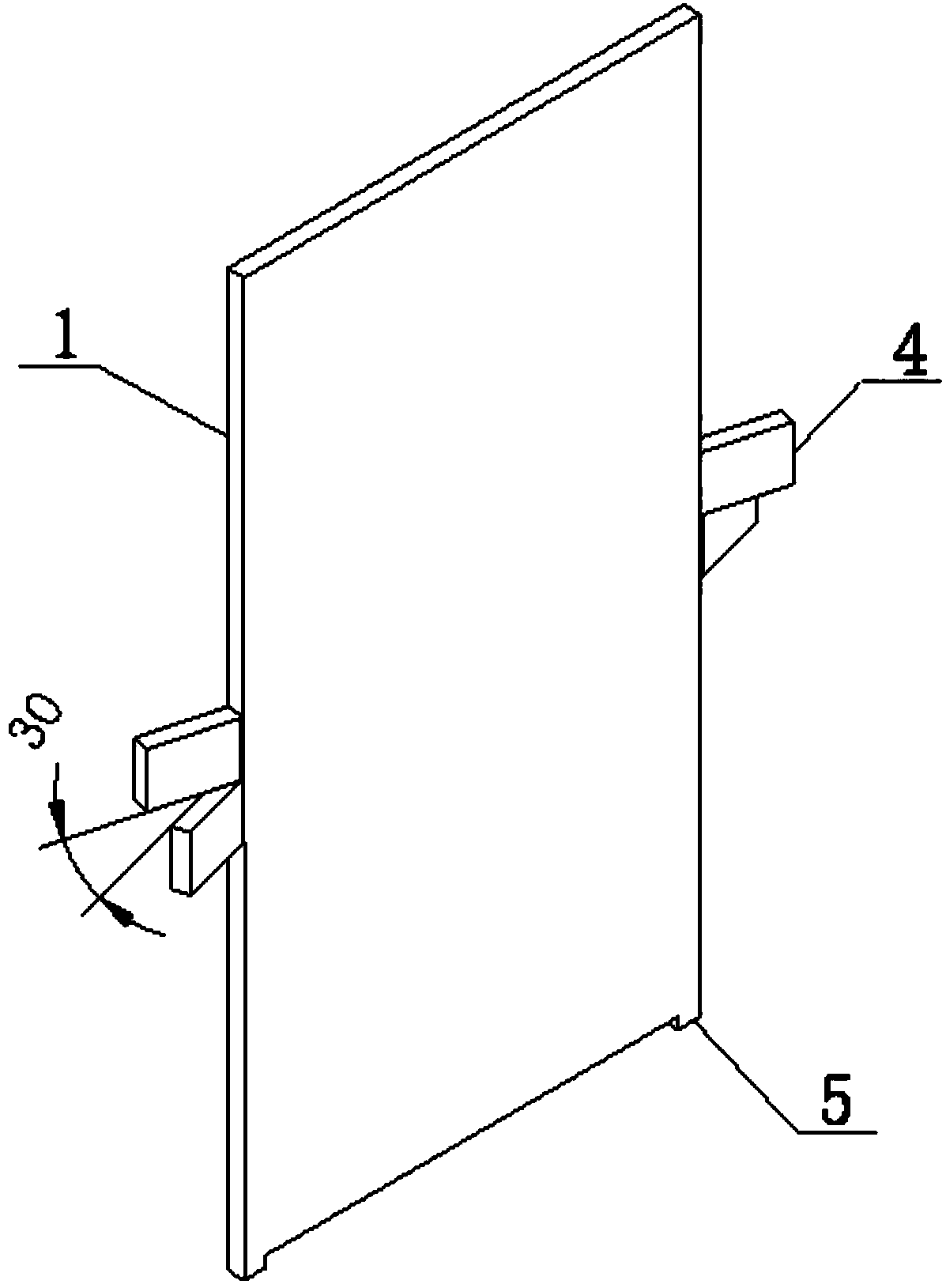

[0023] Such as image 3 As shown, the middle parts of the left and right sides of the reinforced support plate 1 are respectively provided with two positioning pieces 4, and the angle between the two positioning pieces 4 on the same side is 30 degrees; The right edge part is provided with the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com