Vertically-assembled balance arm mechanism and adjustment method thereof

An adjustment method and a technology of a balance arm, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as increasing production costs, increasing labor intensity of operators, and difficulty in vertical wrench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

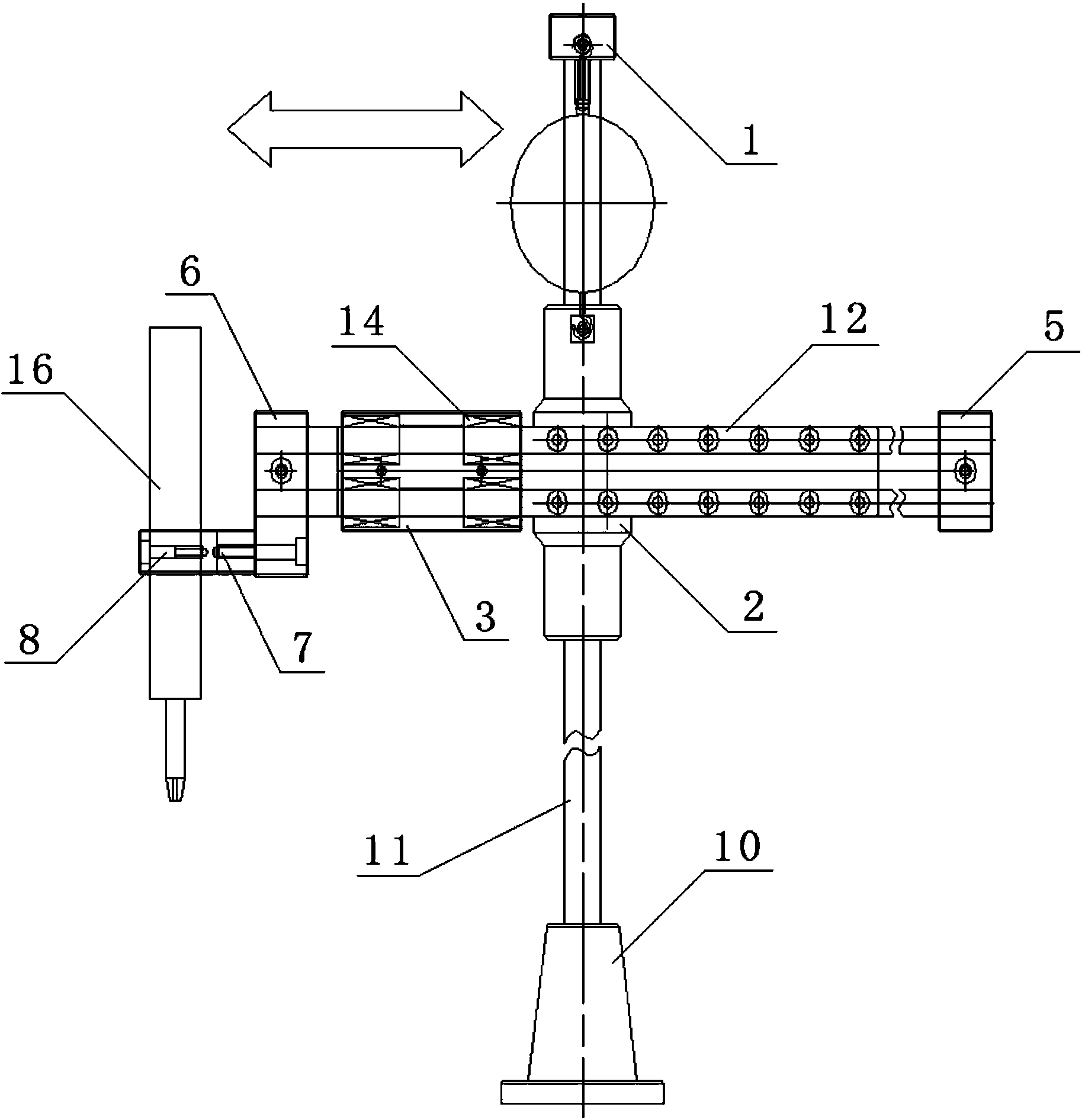

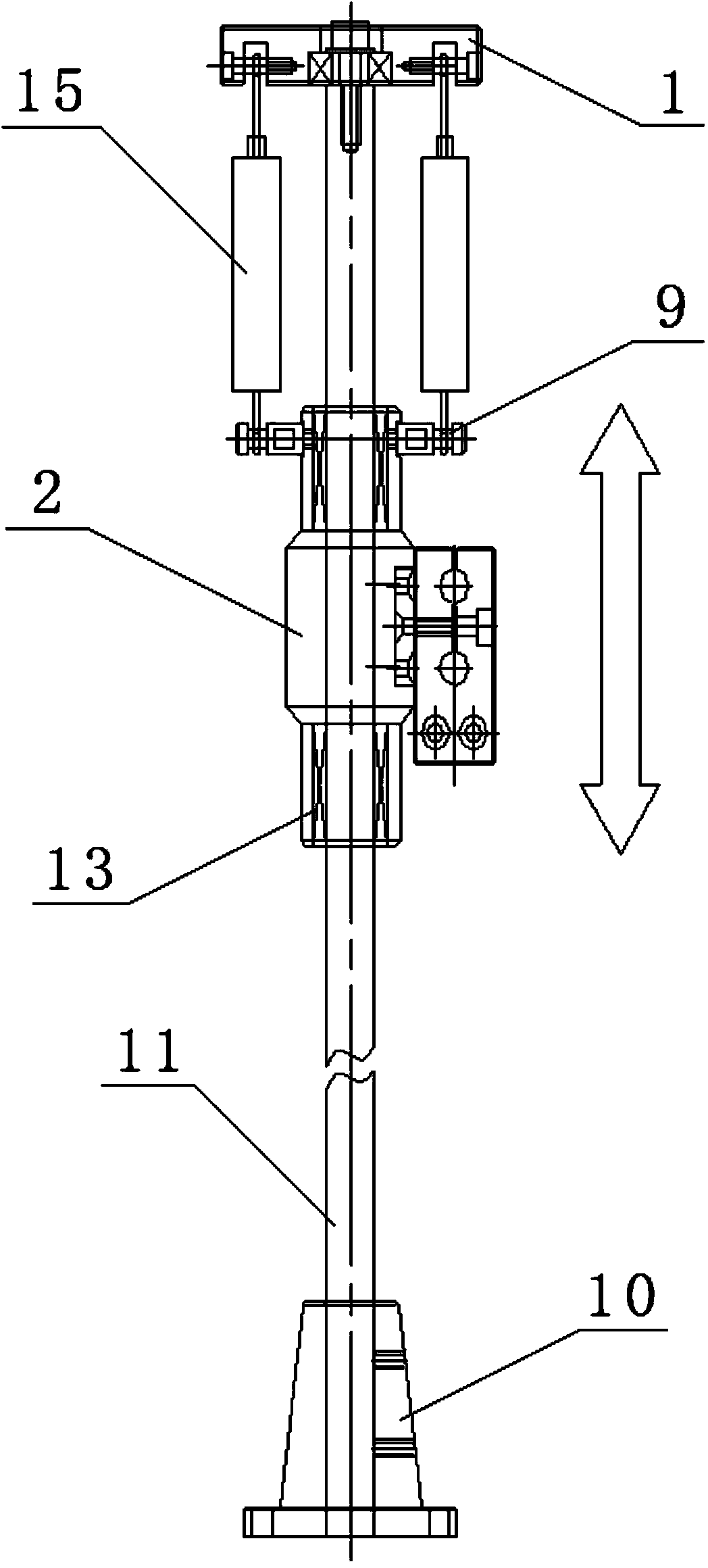

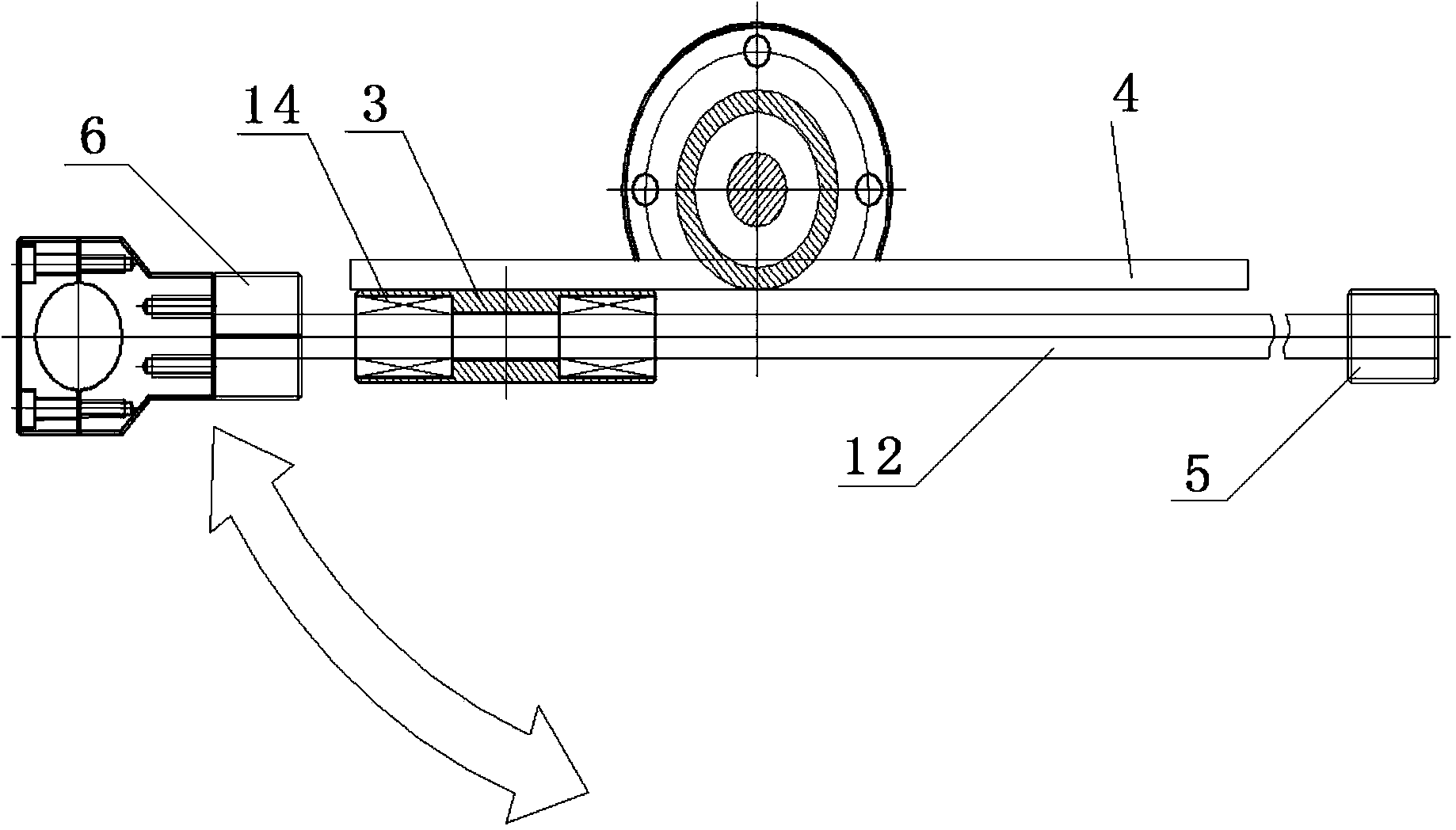

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Left view of the structure shown, image 3 for figure 1 Top view of the structure shown. Depend on Figure 1-Figure 3 Combining the structures shown, it can be seen that this kind of balance arm mechanism for vertical assembly includes a base 10 and a guide column 11 located on the base 10. A sliding sleeve 2 is installed in the middle of the guide column 11, and the two ends of the sliding sleeve 2 are respectively installed. There is a first linear bearing 13, and the sliding sleeve 2 and the first linear bearing 13 are set on the guide rod column 11, and the middle part of the sliding sleeve 2 is installed with a horizontal sliding plate perpendicular to the axial direction of the sliding sleeve 2 4. The horizontal slide 4 is provided with several assembly and installation points that cooperate with the sliding sleeve 2; the top of the guide rod column 11 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com