Machining detection method for improving part edge surface integrity

A surface integrity and detection method technology, applied in metal processing equipment, control of workpiece feed movement, manufacturing tools, etc., can solve the problems of low quality of edge processing of parts, affecting the overall fatigue performance of parts, poor consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

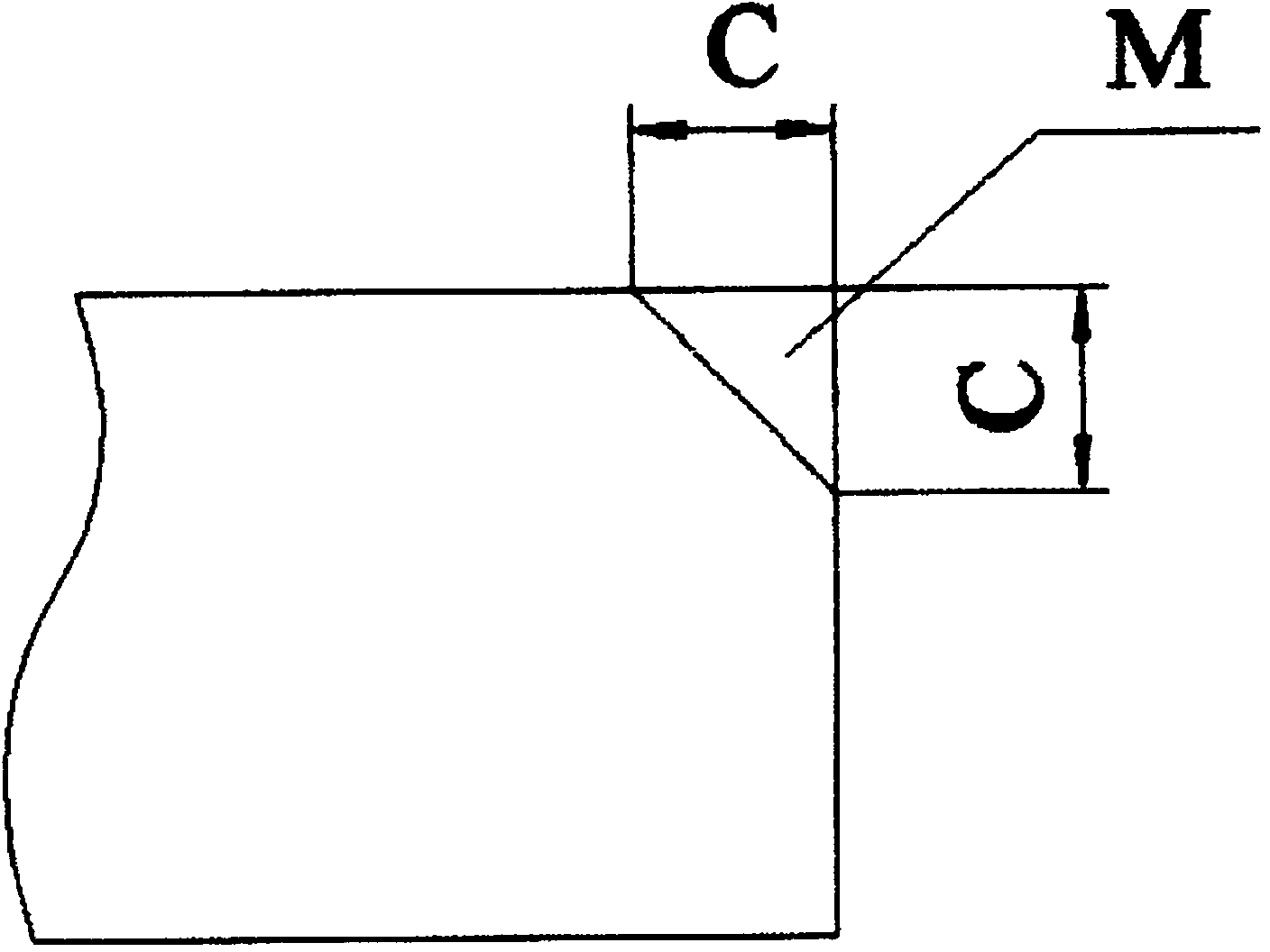

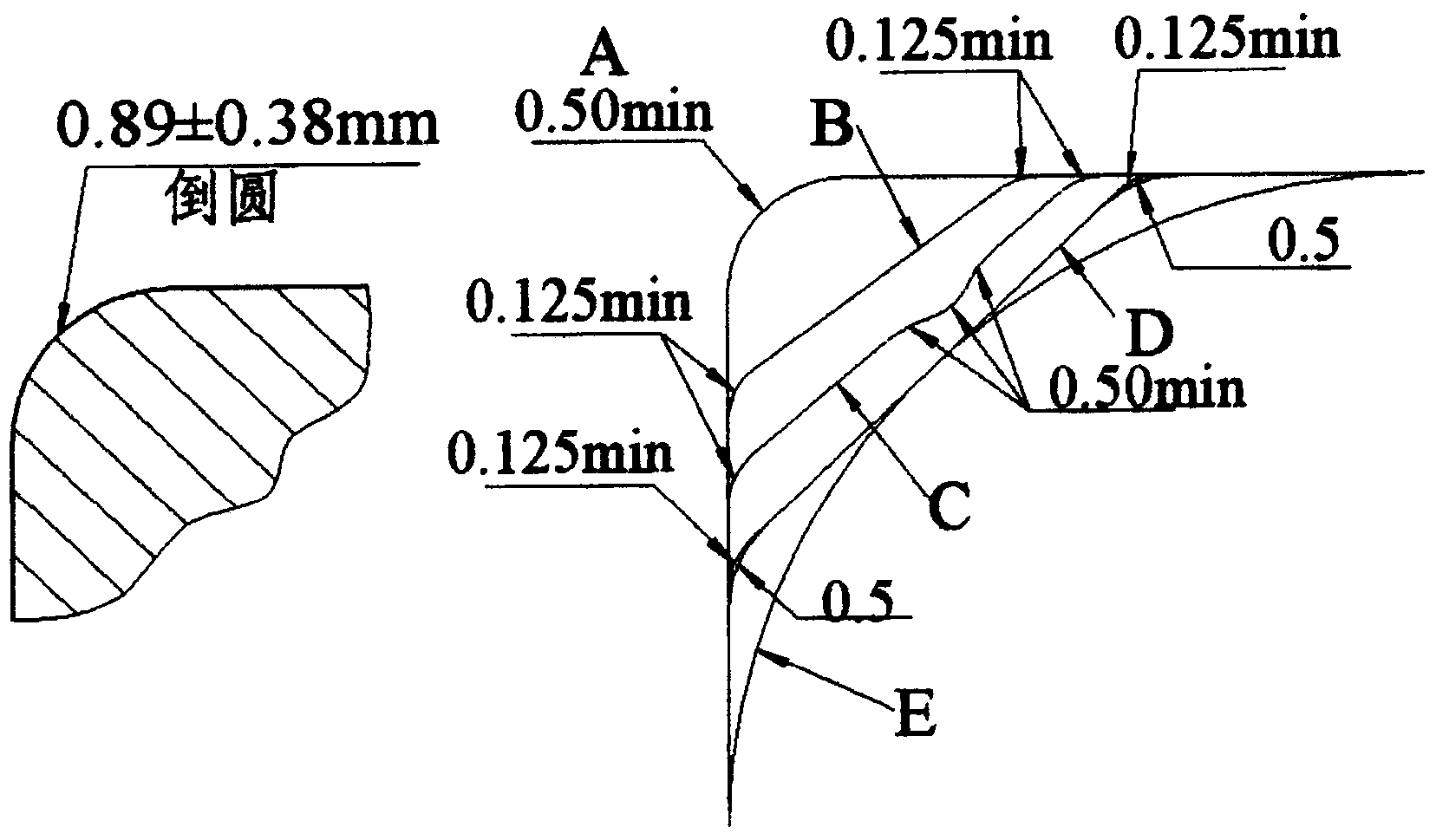

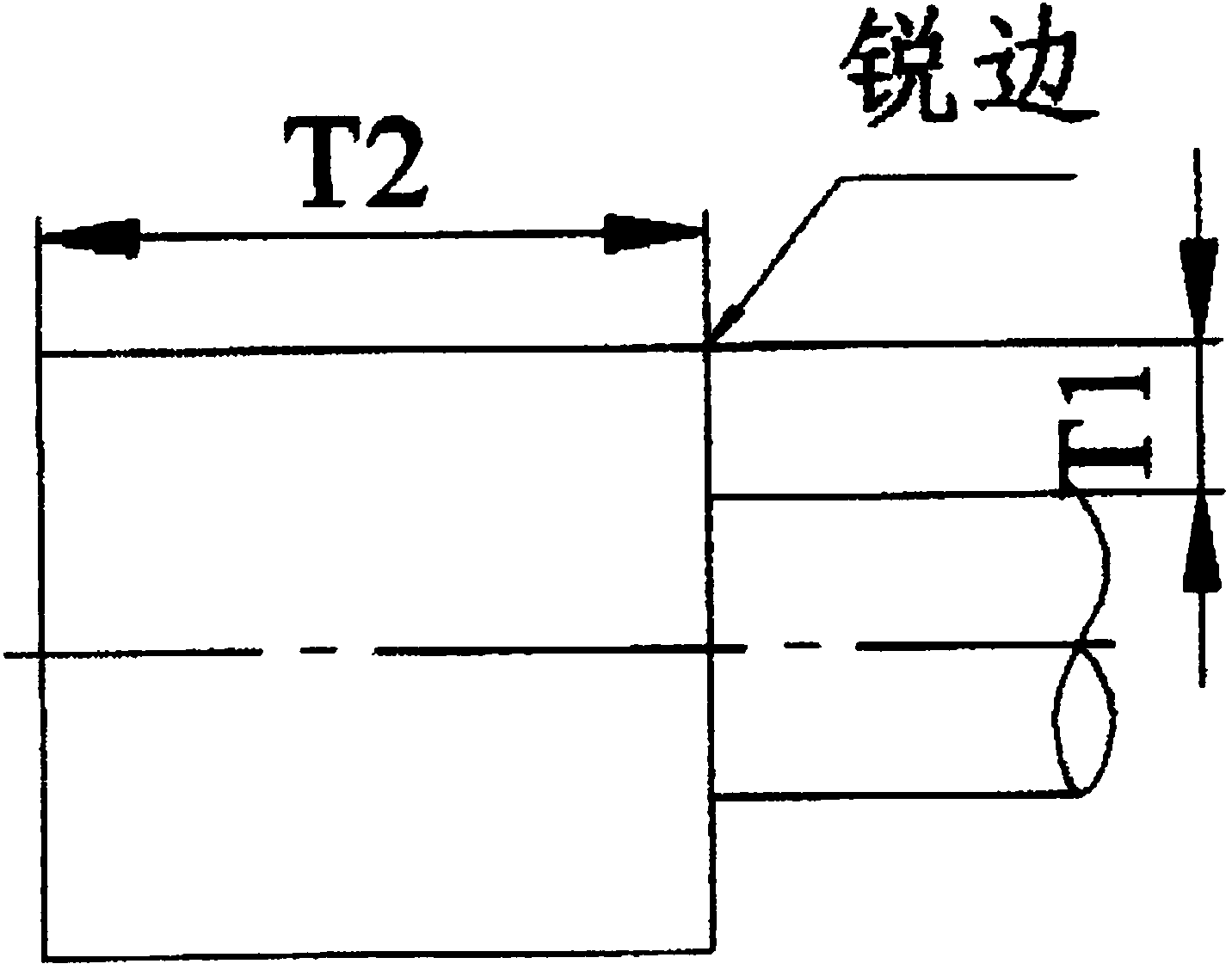

[0023] The present invention combines the existing conditions and development potential, perfects and refines the basic standards, and clearly and meticulously specifies the edge processing of parts, including the requirements for rounding and chamfering and the determination of deviations:

[0024] 1) For 45-degree chamfers and roundings that are not specified in the design drawings, follow the provisions of HB5800-1999 "General Tolerances".

[0025] 2) For the 45° chamfer, the provisions of HB5800-1999 "General Tolerance" are more detailed than foreign technical documents, but the limit deviation is slightly looser than that of foreign technical documents when some dimensions are divided. Combined with the company's Technical ability, the tolerance of the 0.3-6mm size segment is tightened. The specific differences are shown in Table 1:

[0026] Table 1 Comparison of differences between the original technical document and this technology

[0027]

[0028] 3) For chamfers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com