Automatic sand blasting and rust removal device

An automatic sandblasting and rust removal technology, which is applied in the direction of explosion generating devices, used abrasive processing devices, spray guns, etc., can solve problems such as no product, stop test exploration, double-head difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

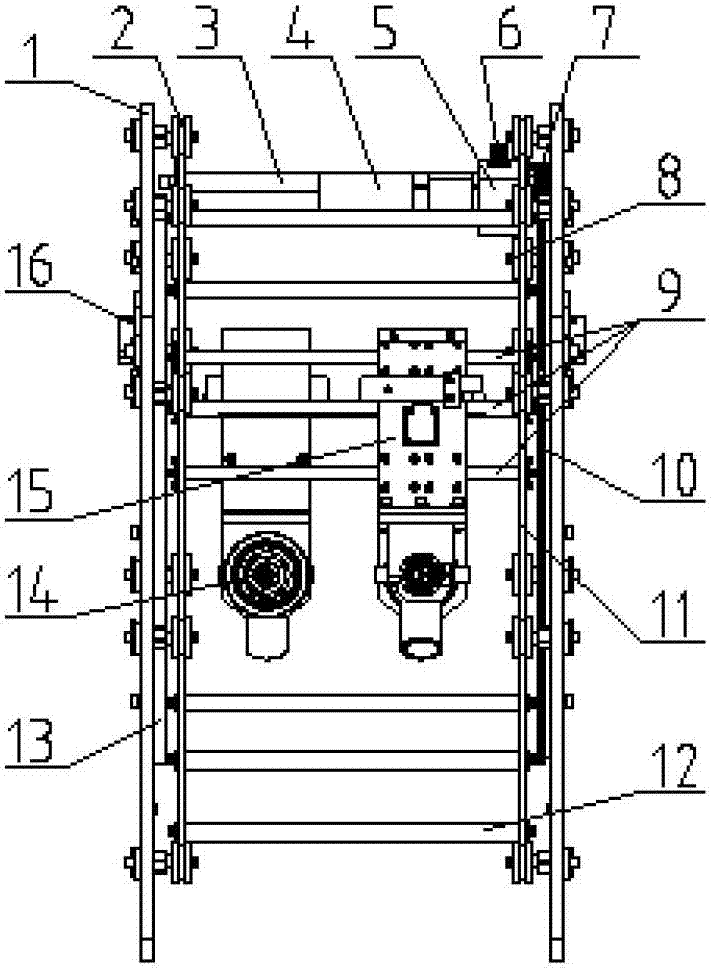

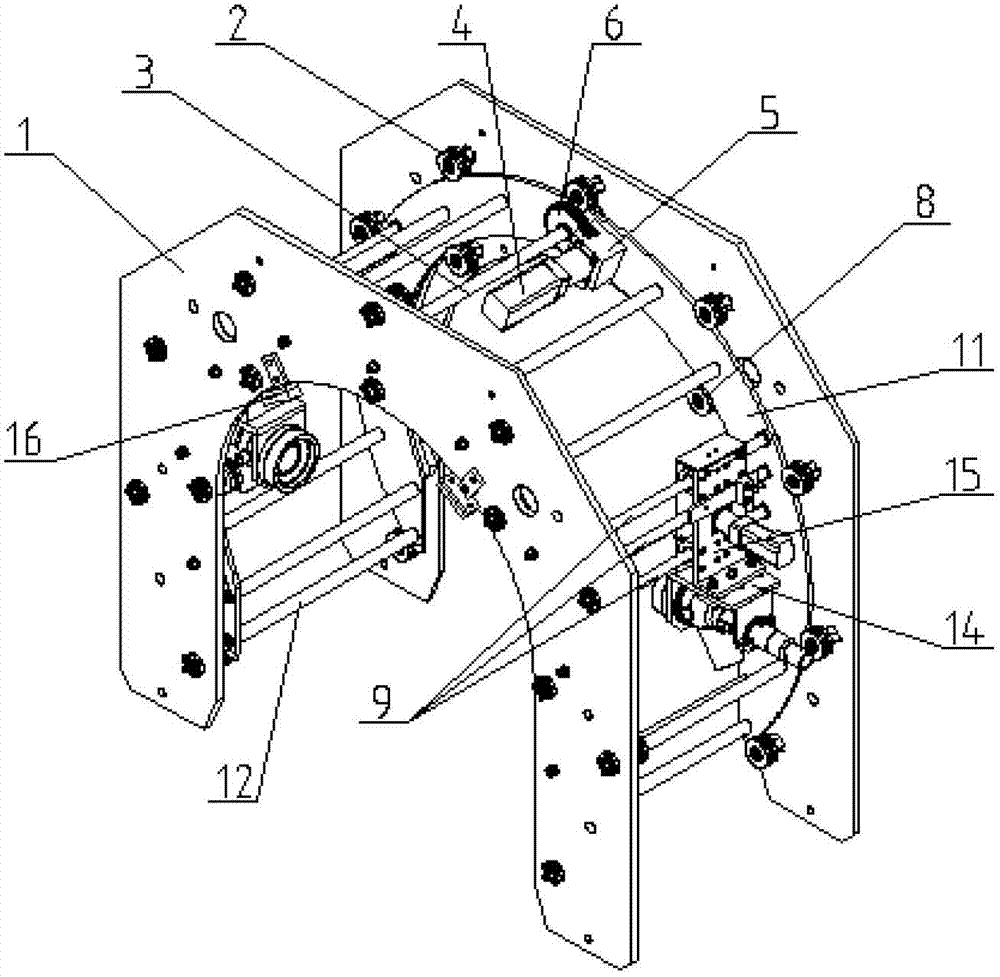

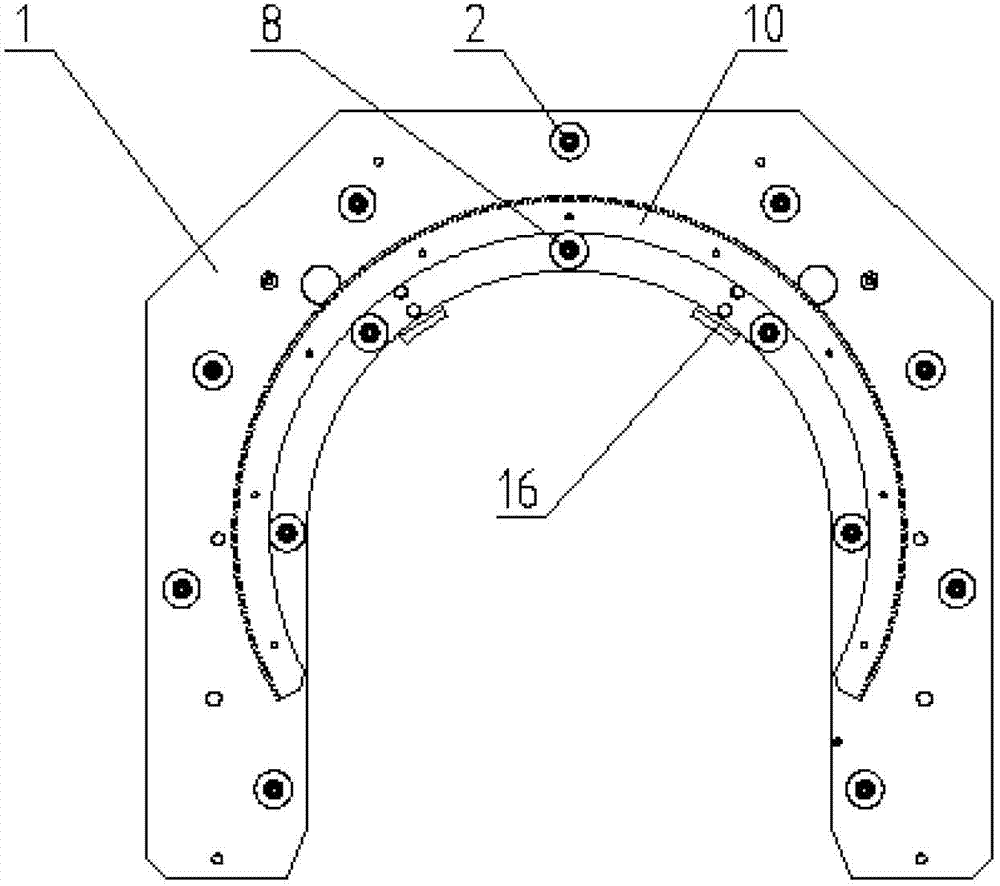

[0022] Taking an automatic sandblasting and derusting device with a pipe diameter of Φ762mm as an example, the present invention will be further described in detail.

[0023] Support plate 1 made of 1 common rolled steel plate with a wall thickness of 14mm, 9 pieces of outer guide wheels 2 and 5 pieces of inner guide wheels 8, with 4mm eccentric adjustment, ring gear with 120° opening 10, 2 sets and pipes There are 40×80mm 2 The supporting feet 16 on the contact surface form a support assembly; the only difference between the other support assembly and it is that the ring gear 10 is replaced by a reinforcing ring 13, and the dimensions of the two are exactly the same.

[0024] It consists of a stepped transmission shaft 3, a servo motor 4 with an output power of 200W, a motor support seat 5 made of an 85×80×60mm aluminum alloy block, a transmission gear 6 with a module of 1.5 and a number of teeth of 57, and a module of 4. The number of teeth is 19 drive gears 7, 2 groups of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com