Two-way hydraulic putty sprayer

A putty spraying machine, two-way hydraulic technology, applied in construction, building structure and other directions, can solve the problems of accelerated mechanical wear, low pressure working frequency, and the suction volume cannot meet the requirements of normal work, so as to reduce mechanical wear, improve Effects of media suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

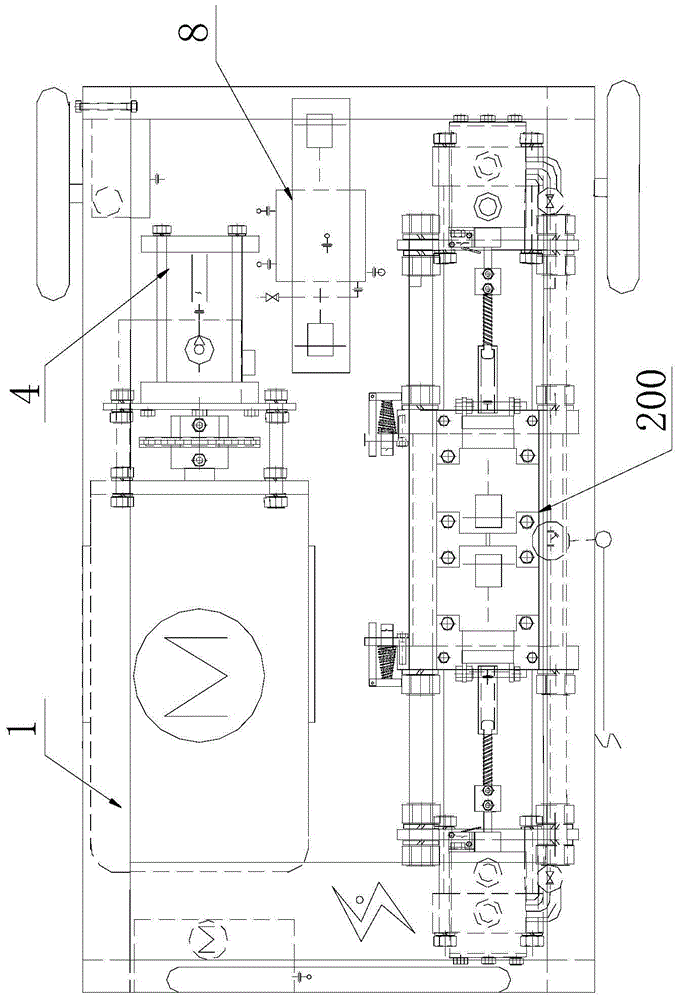

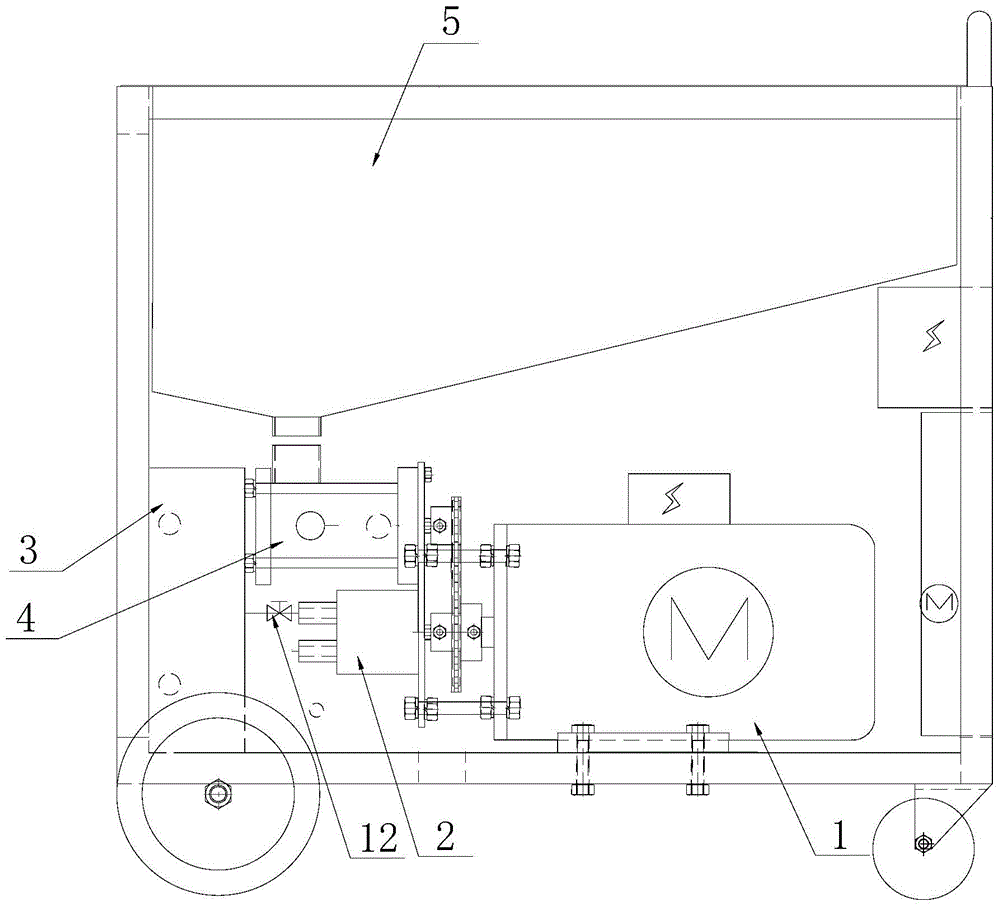

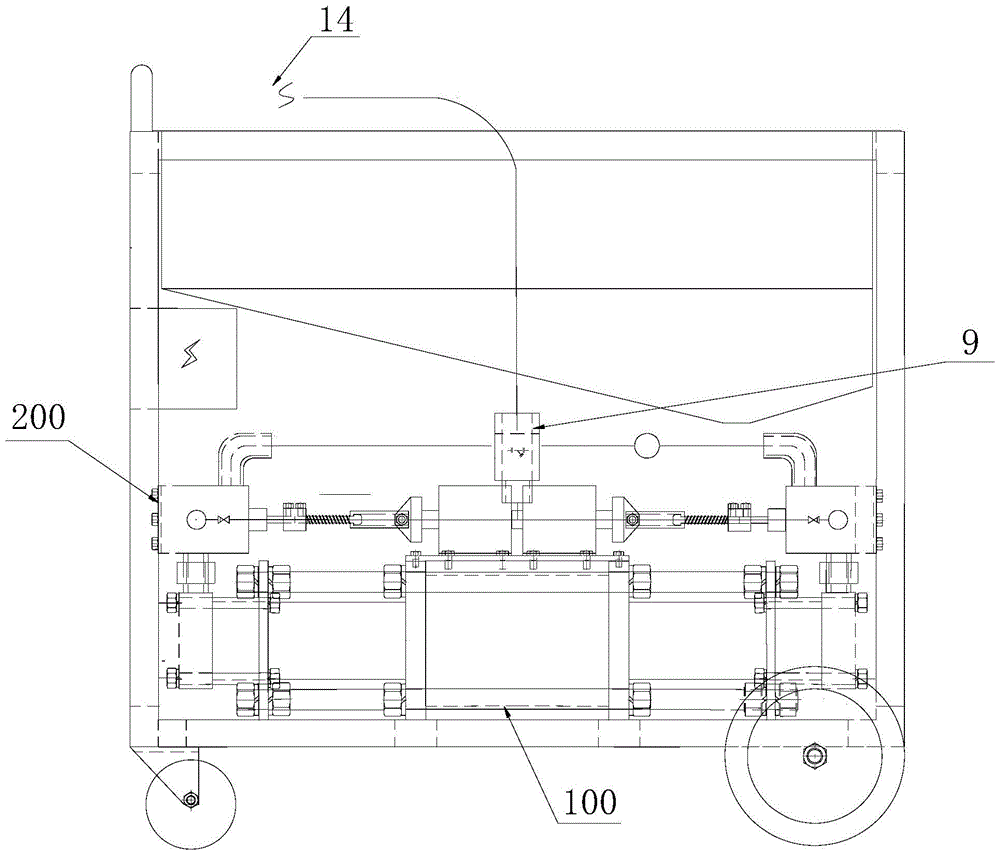

[0041] Such as Figure 1-14 As shown, the two-way hydraulic putty spraying machine includes a motor 1, an oil pump 2, a hydraulic oil radiator 13, an oil tank 3, a medium delivery pump 4, a hopper 5, a two-way hydraulic transformer 100, a linkage electromagnetic plunger high-pressure one-way valve 200, an electromagnetic Steering, positioning switch 7, media outlet 6 and media filter 9. The motor 1 drives the oil pump 2 and the medium delivery pump 4. The oil tank 3 is connected to the input end of the oil pump 2 through the hydraulic oil flow control valve 12. The hydraulic oil radiator 13 is used to dissipate heat and cool the hydraulic oil to avoid overheating of the hydraulic oil. The hopper 5 is connected to the input end of the medium delivery pump 4, and the oil pump 2 is a gear oil pump.

[0042] The bidirectional hydraulic transformer 100 includes a main cylinder 110 , a main piston 120 , a first auxiliary cylinder 130 , a first auxiliary plunger 140 , a second auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com