Tower crane integral steel frame aisle and manufacturing method thereof

A production method and integrated technology, which can be applied to the on-site preparation of building components, construction, building construction, etc., can solve problems such as hidden safety hazards, and achieve the effects of convenient construction and installation, strong practicability, and accelerated construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

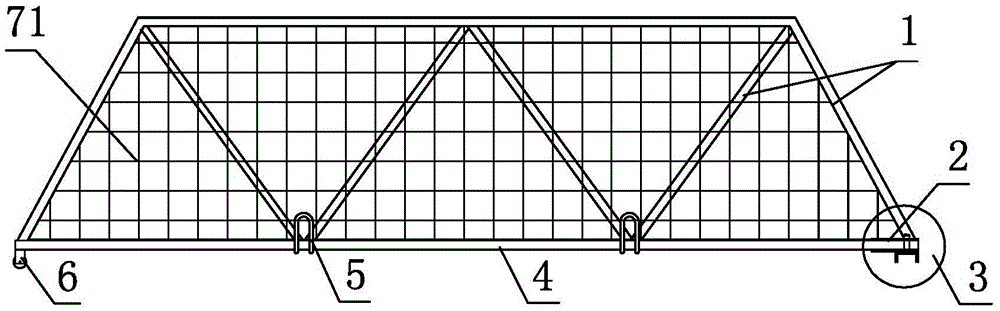

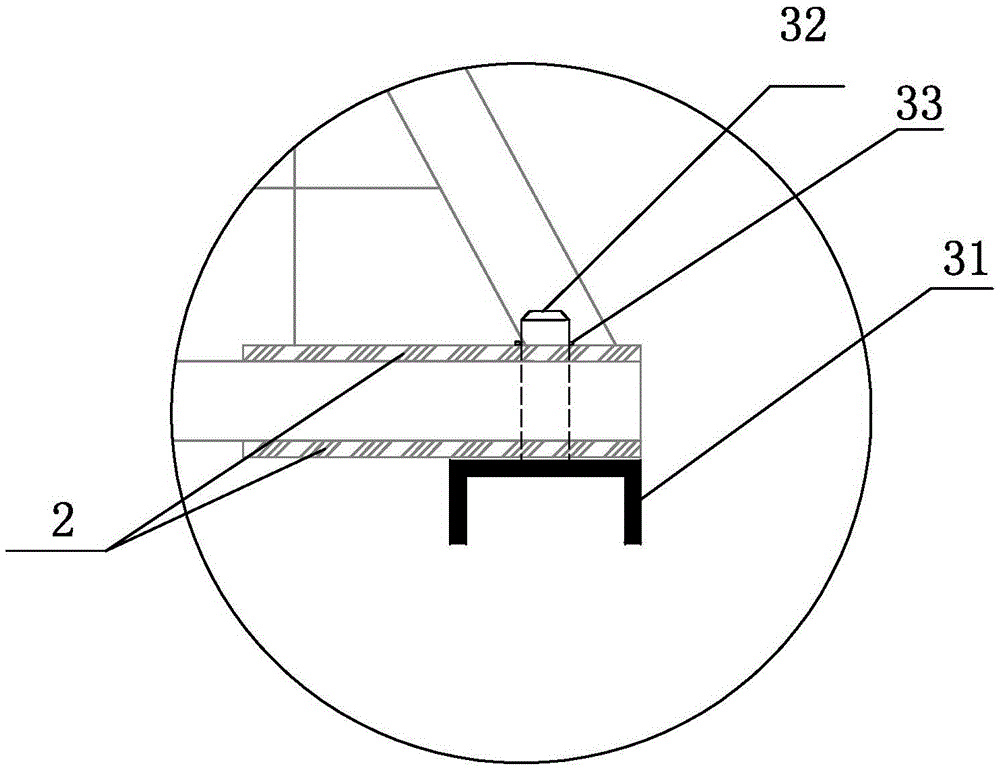

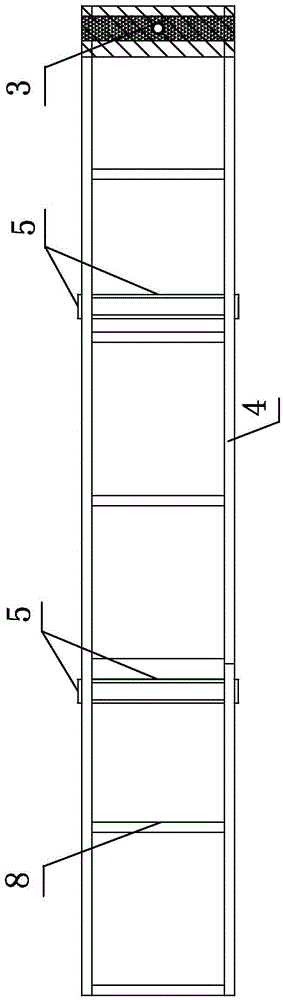

[0041] A tower crane integral steel frame aisle, such as Figure 1 to Figure 4 As shown, the tower crane integral steel frame aisle is an integral steel frame composed of a steel main beam 4, a steel secondary beam 8, a steel guardrail 1, a reinforced steel plate 2, and a protective net. As the main load-bearing force of the integral steel frame The two steel main girders 4 of the component are located at the bottom of the integral steel frame, the two parallel steel main beams 4 are connected with multiple steel secondary beams 8 in the middle, and the two parallel steel main beams 4 are respectively equipped with multiple steel guardrails 1 , the profiled steel guardrail 1 is used as the guardrail structure of the tower crane integral steel frame aisle body, and can form a steel truss with the profiled steel girder 4 to improve the bearing capacity of the aisle; there is a protective vertical net 71 on the side of the integral aisle (see figure 1 ), used for the side protect...

Embodiment 2

[0048] A method for manufacturing a tower crane integral steel frame aisle, the tower crane integral steel frame aisle imitates the structure and function of a bridge, and is integrally welded with materials such as steel pipes and square steel, and the specific method steps include:

[0049] A. Manufacture and weld the steel skeleton of the integral steel frame aisle of the tower crane:

[0050] ① According to the design length of the aisle, the materials of various steel parts and steel components are placed: the various steel parts and steel components include steel main girder 4, steel secondary beam 8, steel guardrail 1 and reinforced steel plate 2;

[0051] ② Weld and assemble the section steel guardrail 1 and the section steel main beam 4 in turn according to the drawings to obtain the steel truss; then weld the reinforced steel plate 2, the safety ring 5 and the section steel secondary beam 8 according to the drawings, and finally obtain the steel skeleton of the entire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com