Method for determining heavy oil thermal recovery steam chamber state

A heavy oil thermal recovery and steam chamber technology, which is applied in the fields of fluid production, earthwork drilling, measurement, etc., can solve the problems of high cost, uncertainty of the shape and development of the steam chamber, etc., and achieves the effect of reducing investment and improving description ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The method for determining the shape of the steam chamber for thermal recovery of heavy oil is realized through the following specific steps:

[0040] 1) Measure the production well data of the heavy oil reservoir in the exploration area, and collect the structural form data of the oil reservoir in the exploration area;

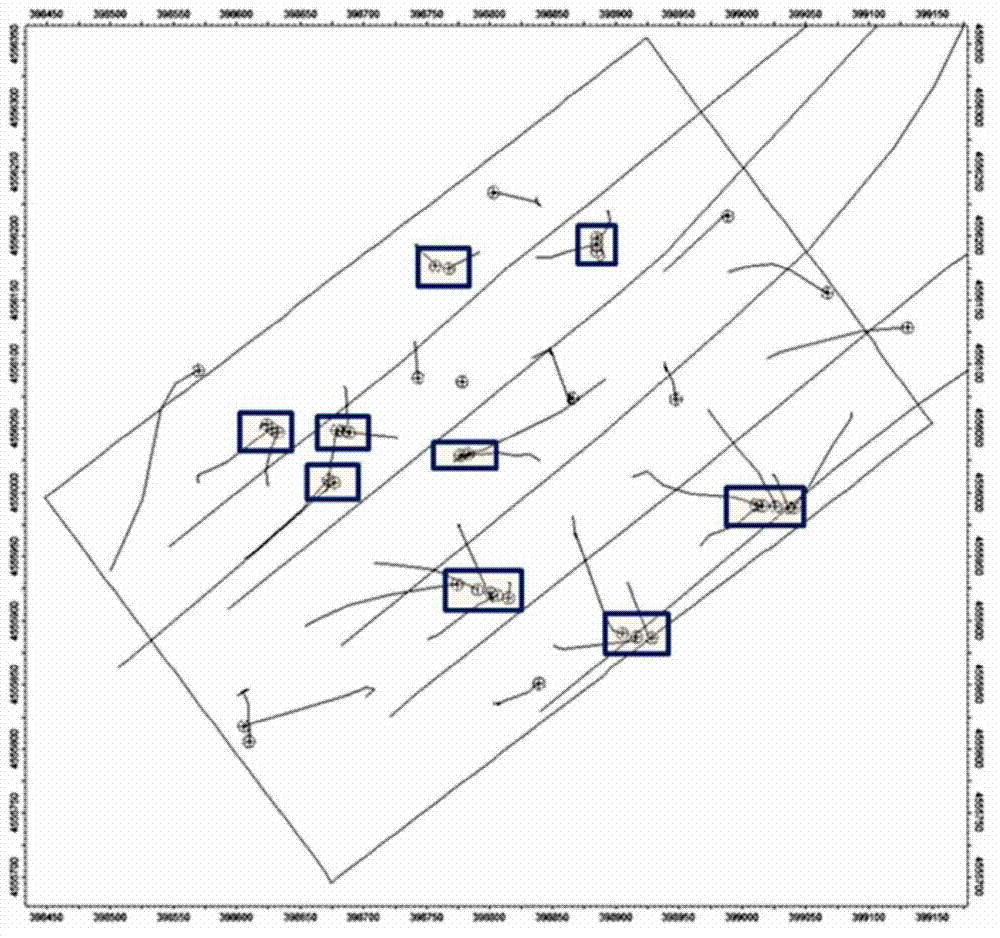

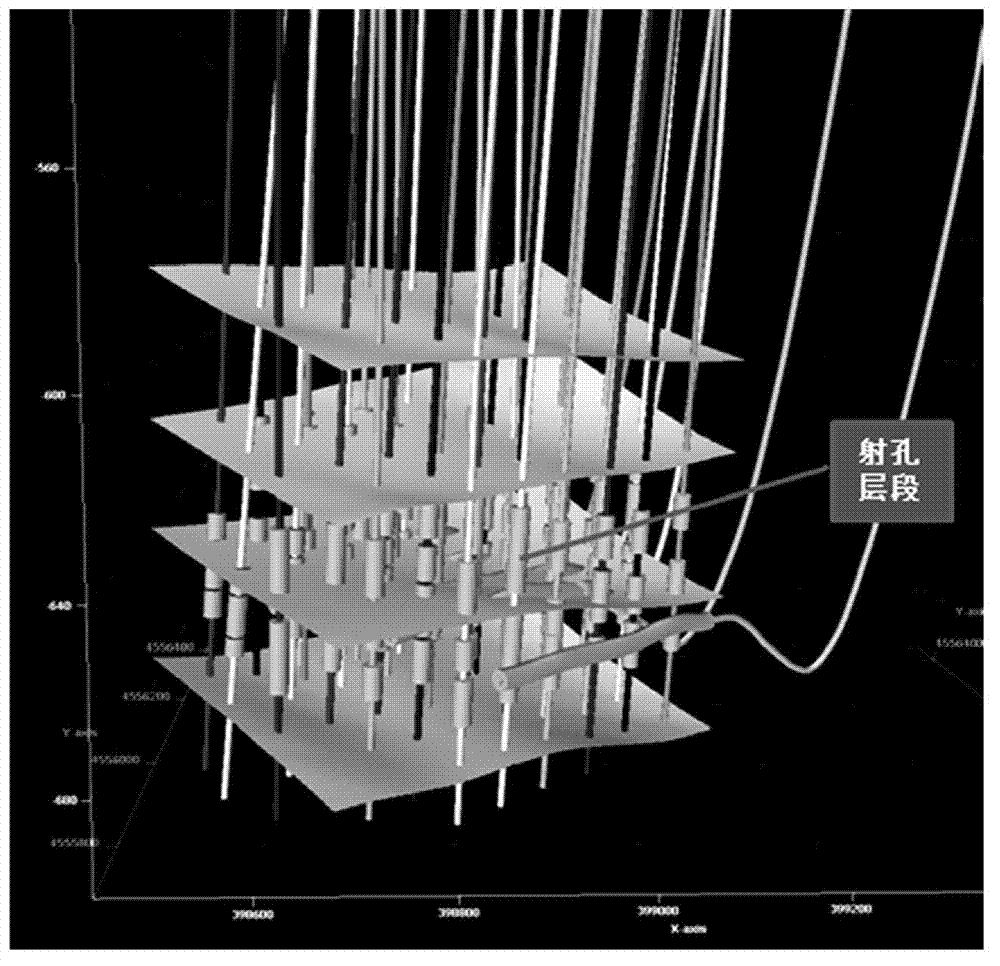

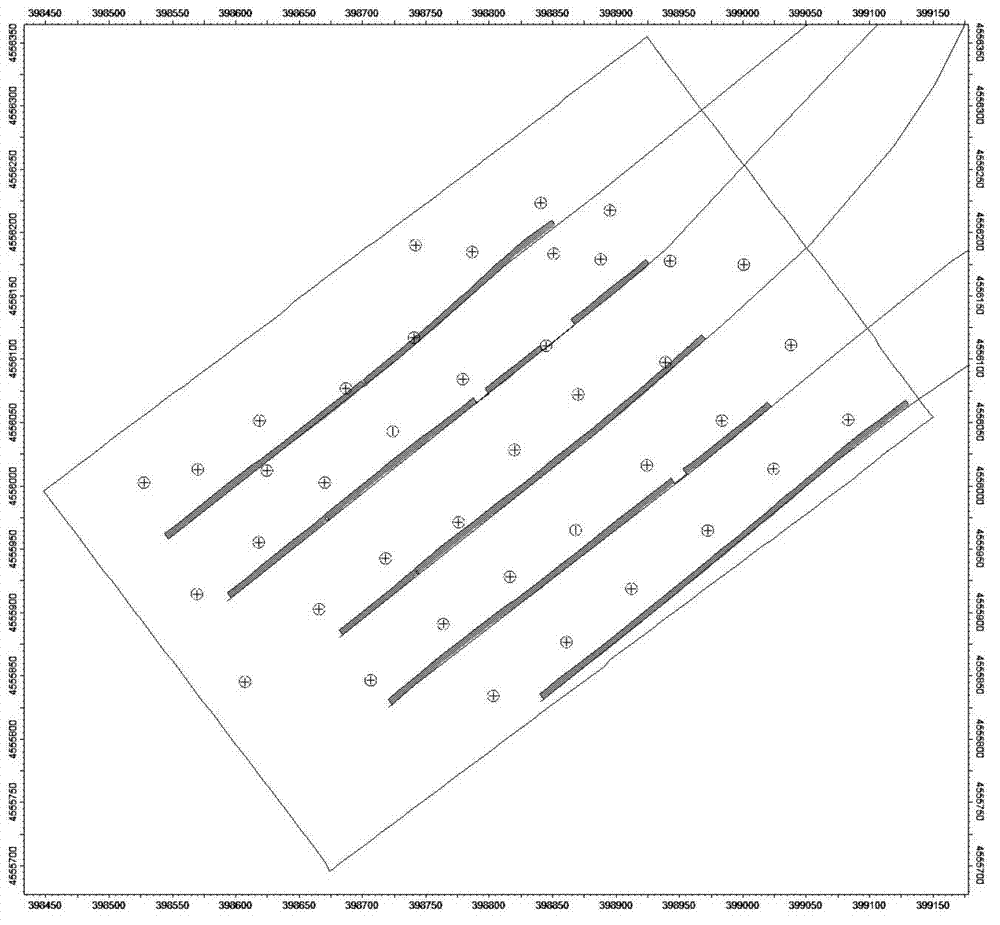

[0041] The measured well data of production wells in heavy oil reservoirs in the exploration area includes the wellbore-related data of measured steam injection wells and oil production wells, including wellhead coordinates, well trajectory, perforation intervals and layered data. These data determine the spatial position relationship of the wells in the reservoir, and also determine the area where the production of the wells has an effect on the reservoir and the spatial configuration relationship among them. figure 1 It is the wellhead coordinates and wellbore trajectory plane distribution map of production wells in the exploration area. The abscissa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com