Spiral elastic piece heat dissipation driven disk assembly

An elastic sheet and spiral technology, applied in the field of clutches, can solve the problems of accelerating clutch wear, reducing clutch service life, adverse effects of clutch heat dissipation, etc., to achieve the effect of reducing wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

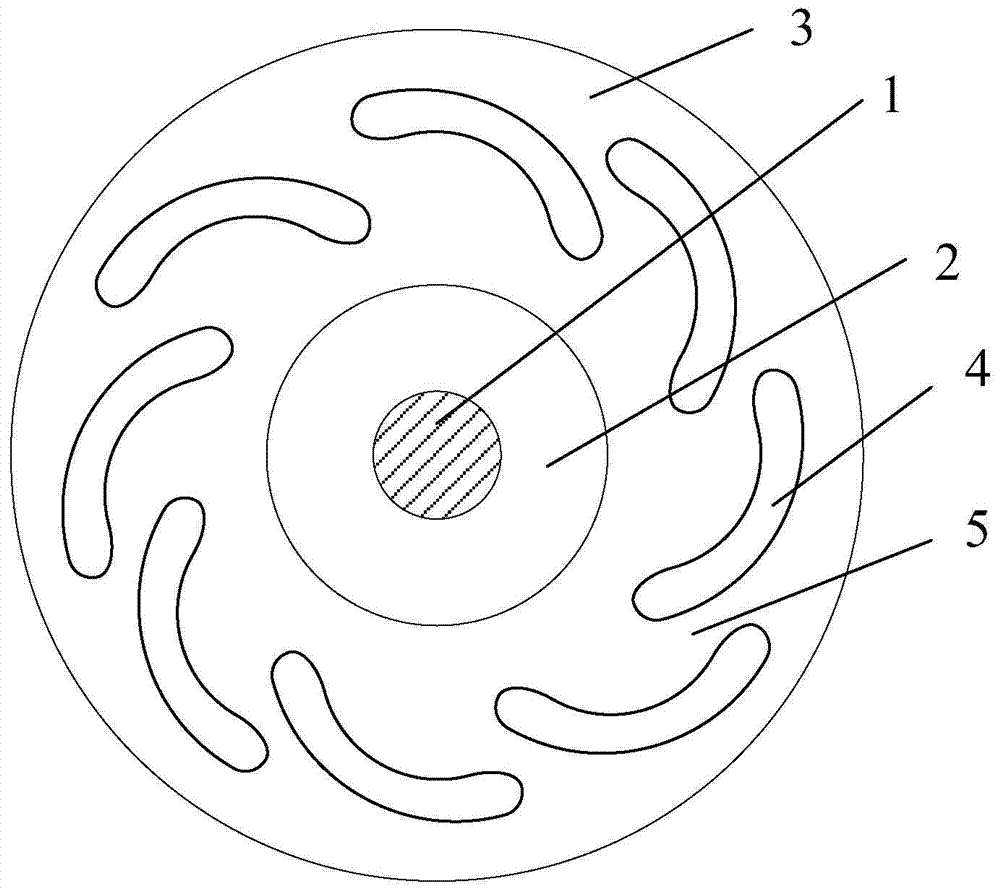

[0013] Such as figure 1 and figure 2 as shown, figure 1 It is a front view of a helical elastic heat dissipation driven plate assembly in the embodiment of the present invention; figure 2 yes figure 1 Schematic diagram of the cross-sectional structure of the middle elastic sheet.

[0014] refer to figure 1 , the embodiment of the present invention provides a helical elastic plate cooling driven disk assembly, including: driven disk 3, damping disk 2 and disk hub 1; driven disk 3 is fixedly connected with vibration damping disk 2 through rivets Set on the hub 1, an elastic pad is provided at the connecting part of the driven disk 3 and the damping disk 2; a plurality of spirally distributed elastic sheets 4 are arranged on the circumference of the driven disk 3, and the space between two adjacent elastic sheets 4 Airflow channels 5 are formed.

[0015] In a specific embodiment, the elastic piece 4 has a long arc structure, the outer arc of the elastic piece 4 faces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com