Method for detecting mechanical property of self-piercing riveting joint

A detection method and self-piercing riveting technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as the inability to extract the characteristic quantities of internal lock slippage of riveting buckles, and achieve high use value and significance, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

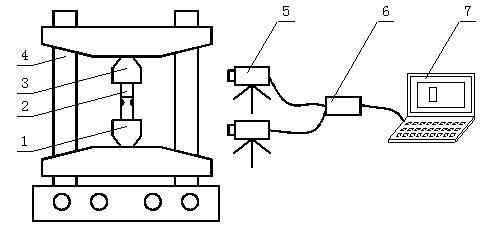

[0049] Embodiment 1: A method for testing the mechanical properties of self-piercing riveted joints. The testing system is mainly composed of a material mechanical properties testing machine, an electron microscope, and a computer that controls image acquisition and image analysis, and mainly includes the following steps:

[0050] Step 1. Forming of plate self-piercing riveting joints:

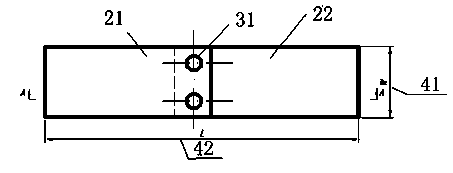

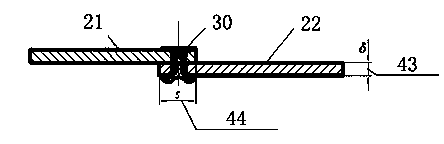

[0051] like figure 2 , image 3 As shown, process two metal plates of the same size with a length of 150 mm, a width of 40 mm, and a thickness of 2 mm, and overlap them along the length direction of the two plates. The lap size is 50 mm and the two sides of the plate length direction are aligned. , using riveting equipment to sequentially process and form double rivet self-piercing riveting joints at the overlapping joints of the plates and along the width direction of the plates;

[0052] Step 2. Processing of double riveted joint specimens:

[0053] Use wire electric discharge cutting eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com