Laminated electrode on a light-emitting device

A technology of laminated electrodes and light-emitting devices, which is applied to semiconductor devices, circuits, electrical components, etc., can solve the problems of lowering the light output performance of semiconductor light-emitting devices, reducing the reflectivity of contact electrodes, etc., so as to improve the light output characteristics and avoid voids. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

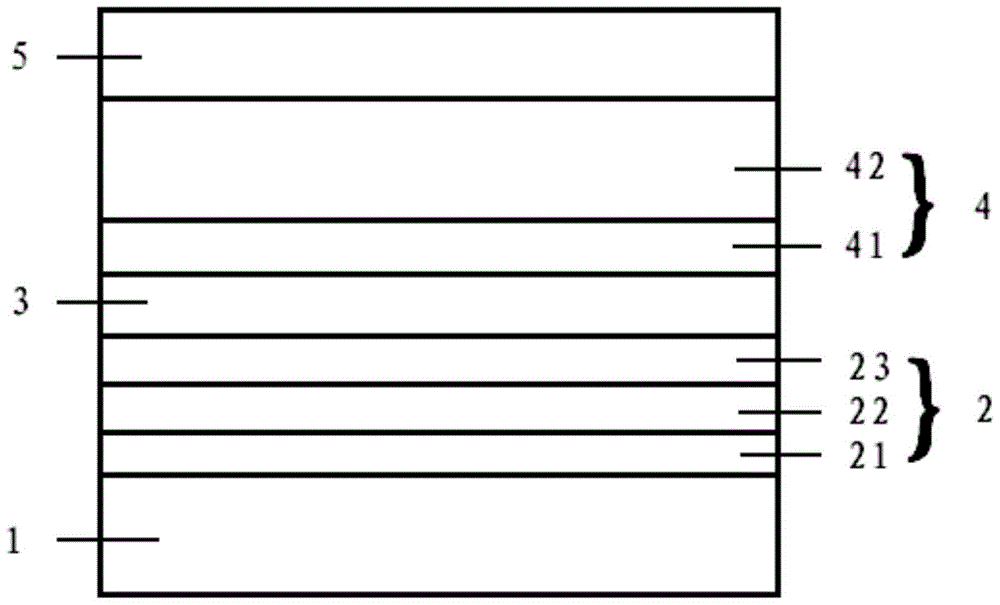

[0015] see figure 1 , the laminated electrode on the light emitting device proposed by the present invention is formed on the semiconductor light emitting unit to be used as an electrode of the semiconductor light emitting unit. The light-emitting device is on a sapphire substrate ( figure 1 (not shown in ), a semiconductor light emitting unit 1 is formed on the semiconductor light emitting unit 1 with a stacked electrode, wherein the stacked electrode includes: a reflective layer 2, a barrier layer 3, a coalescence inhibiting layer 4 and an oxidation shielding layer 5 .

[0016] Among them, the reflective layer 2 is a three-layer structure, from bottom to top: TiO 2 Layer 21, Ti 3 o 5 Layer 2 and Ta 2 o 5 Layer 3, the reflective layer is used to reflect light incident on its surface; TiO 2 Layer 21, Ti 3 o 5 Layer 2 and Ta 2 o 5 Layer 3 has the same thickness;

[0017] The barrier layer 3 is formed by a conductive transparent material, and the conductive transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com