Electromagnetic induction fluorescent lamps for plant growth

An electromagnetic induction and plant growth technology, applied in the field of electric light source lighting devices, to achieve the effects of facilitating plant growth, improving light output characteristics, and saving the amount used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Use a 40W lamp (not exhausted), put in 6mg of amalgam (amalgam), install it on the exhaust table through the connecting pipe, and use a diffusion vacuum pump to pump air to 10 -3 Pa high vacuum, then bake at 480℃ for 0.5~1 hour to remove impurities on the inner wall of the lamp tube, and then fill it with argon gas to make the argon gas pressure reach 100Pa±10Pa. Then open the Krypton gas inflation valve and charge Krypton gas to make the total air pressure reach 360Pa±10Pa. The process is completed by sealing the tube with a flame. After testing, unqualified products are eliminated, and the 40W lamp tube conforming to the technology of the present invention is obtained.

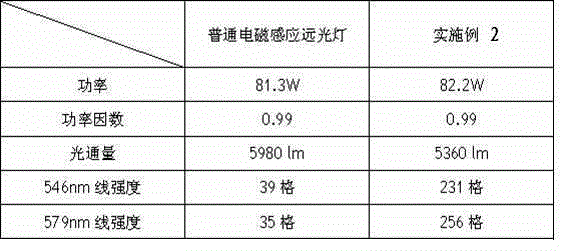

[0013] The common electromagnetic induction fluorescent lamp of equal power compares with embodiment 1:

[0014]

Embodiment 2

[0016] Use an 80W lamp (not exhausted), put in 6mg amalgam (amalgam), install it on the exhaust table through the adapter, and use a diffusion vacuum pump to pump air to 10 -3 Pa high vacuum, then bake at 480℃ for 0.5~1 hour to remove impurities on the inner wall of the lamp tube, and then fill it with argon gas to make the argon gas pressure reach 100Pa±10Pa. Then open the Krypton gas inflation valve and charge Krypton gas so that the total air pressure reaches 220Pa±10Pa. The process is completed by sealing the tube with a flame. After testing, unqualified products are eliminated, and the 80W lamp tube conforming to the technology of the present invention is obtained.

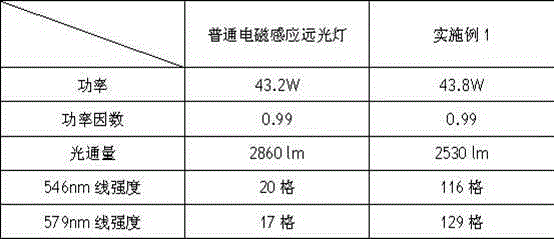

[0017] The common electromagnetic induction fluorescent lamp of equal power compares with embodiment 2:

[0018]

Embodiment 3

[0020] Use a 150W lamp tube (not exhausted), put in 6mg of amalgam (amalgam), install it on the exhaust table through the connecting pipe, and use a diffusion vacuum pump to pump up to 10 -3 Pa high vacuum, then bake at 480℃ for 0.5~1 hour to remove impurities on the inner wall of the lamp tube, and then fill it with argon gas to make the argon gas pressure reach 100Pa±10Pa. Then open the Krypton gas inflation valve, charge Krypton gas to make the total air pressure reach 290Pa, and then seal the tube with a flame to complete the process. After testing, unqualified products are eliminated, and the 150W lamp tube conforming to the technology of the present invention is obtained.

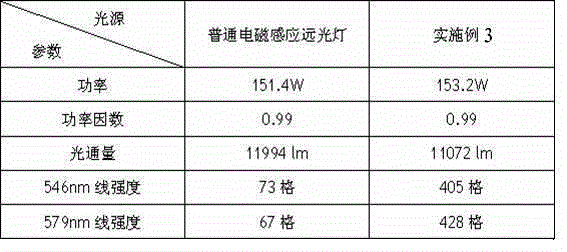

[0021] The common electromagnetic induction fluorescent lamp of equal power compares with embodiment 3:

[0022]

[0023] The current production of electromagnetic induction fluorescent lamps has three powers: 40W, 80W, and 150W. Due to the change in the volume of the lamp tube, the volume of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com