a light emitting device

A technology of light-emitting devices and doped layers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the reflectivity of contact electrodes, reducing the light output performance of semiconductor light-emitting devices, etc., so as to improve the light output characteristics and enhance the ohmic contact. performance, enhance the effect of the limiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

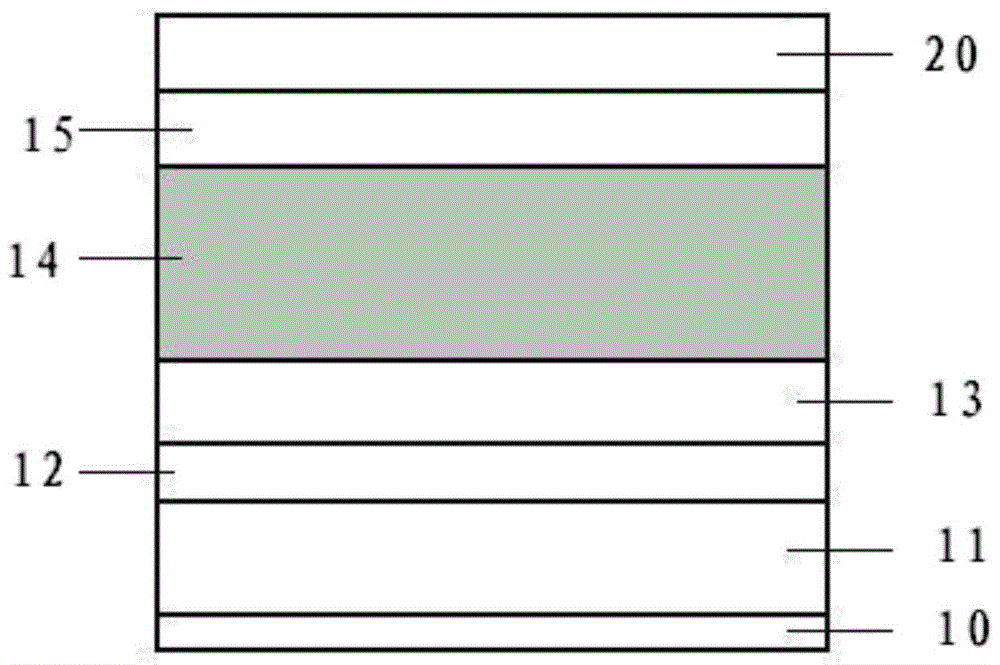

[0017] see figure 1 The structure of the light-emitting device proposed by the present invention is: bottom electrode 10, sapphire substrate 11, low-temperature buffer layer 12, n-type doped layer 13, multiple quantum well layer 14, p-type doped layer 15, Laminate electrodes 20 .

[0018] Wherein, the bottom electrode 10 is a metal electrode, and the metal can be aluminum or copper; the n-type doped layer 13 is made of Al 0.05 In 0.05 Ga 0.9 N is formed, and the p-type doped layer 15 is made of Al 0.1 In 0.05 Ga 0.85 N is formed; the multi-quantum well layer 14 is n-Al 0.045 In 0.055 Ga 0.9 N-tier and n-AI 0.045 In 0.055 Ga 0.9 A periodic structure formed by alternating P layers, with a layer of n-Al 0.045 In 0.055 Ga 0.9 N-layer and one-layer n-AI 0.045 In 0.055 Ga 0.9 P as a cycle, a total of 20-30 cycles are formed;

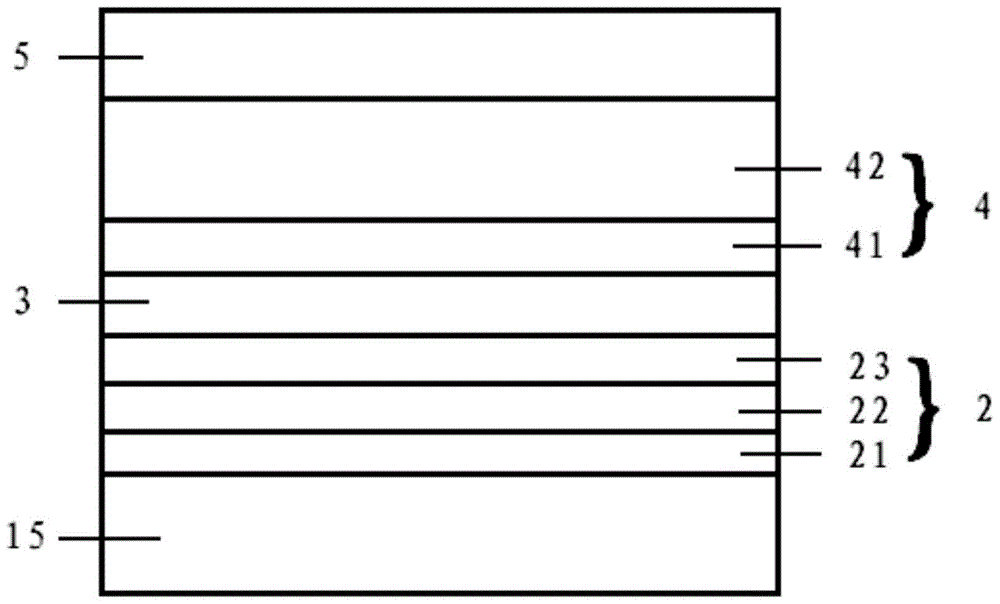

[0019] see figure 2 , the stacked electrode 20 includes: a reflective layer 2 , a barrier layer 3 , a coalescence inhibiting layer 4 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com