Automatic sorting machine for lithium batteries

An automatic sorting, lithium battery technology, applied in sorting, measuring electricity, measuring electrical variables and other directions, can solve the problems of low test sorting efficiency, high labor intensity, easy to mix discharge, etc., to achieve stable and reliable test process, Improve work efficiency and test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

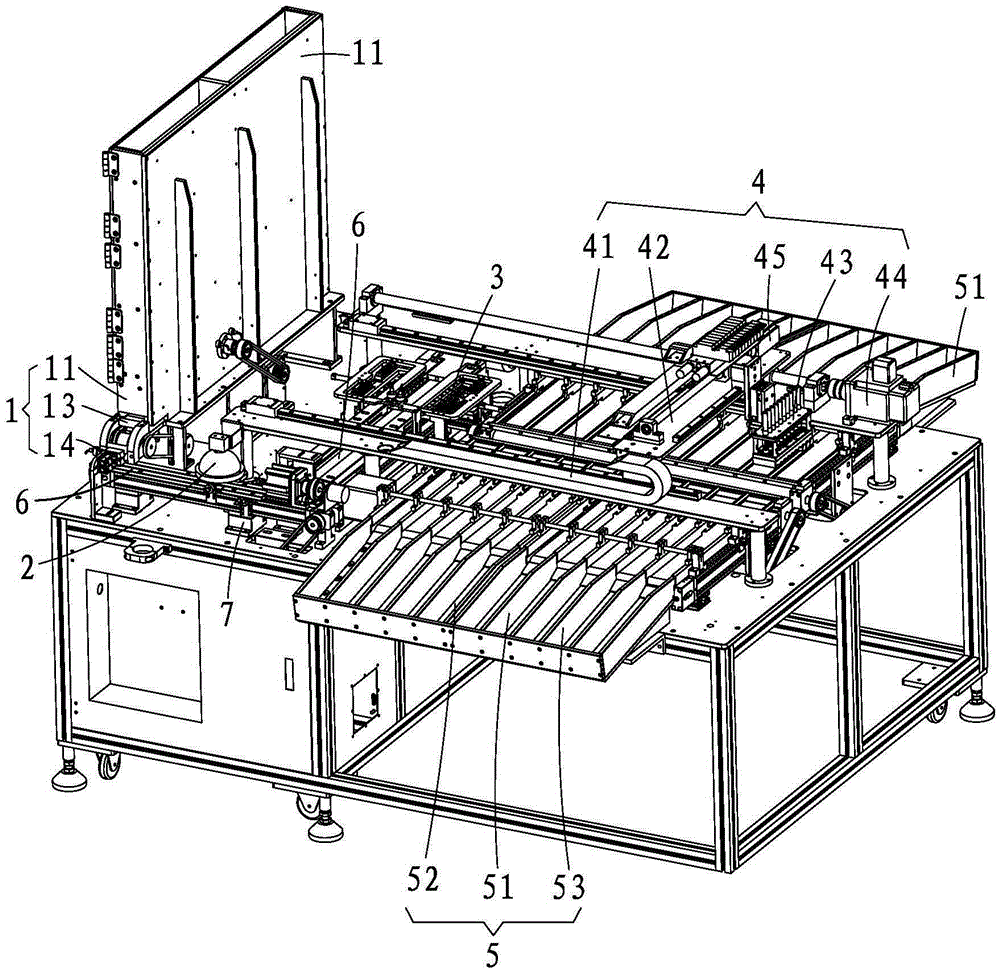

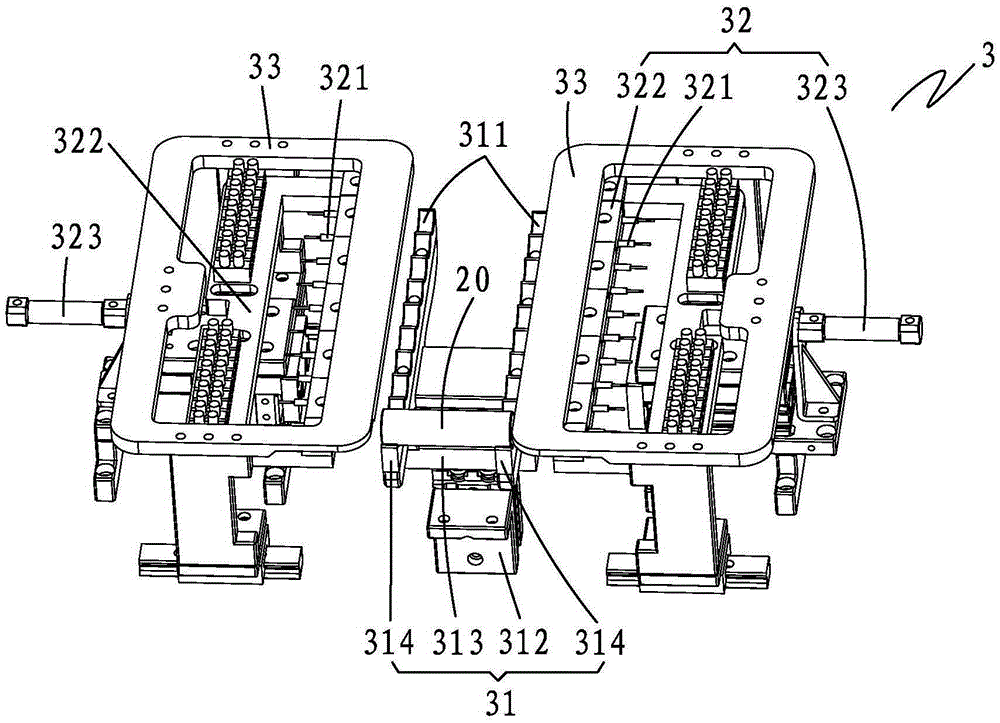

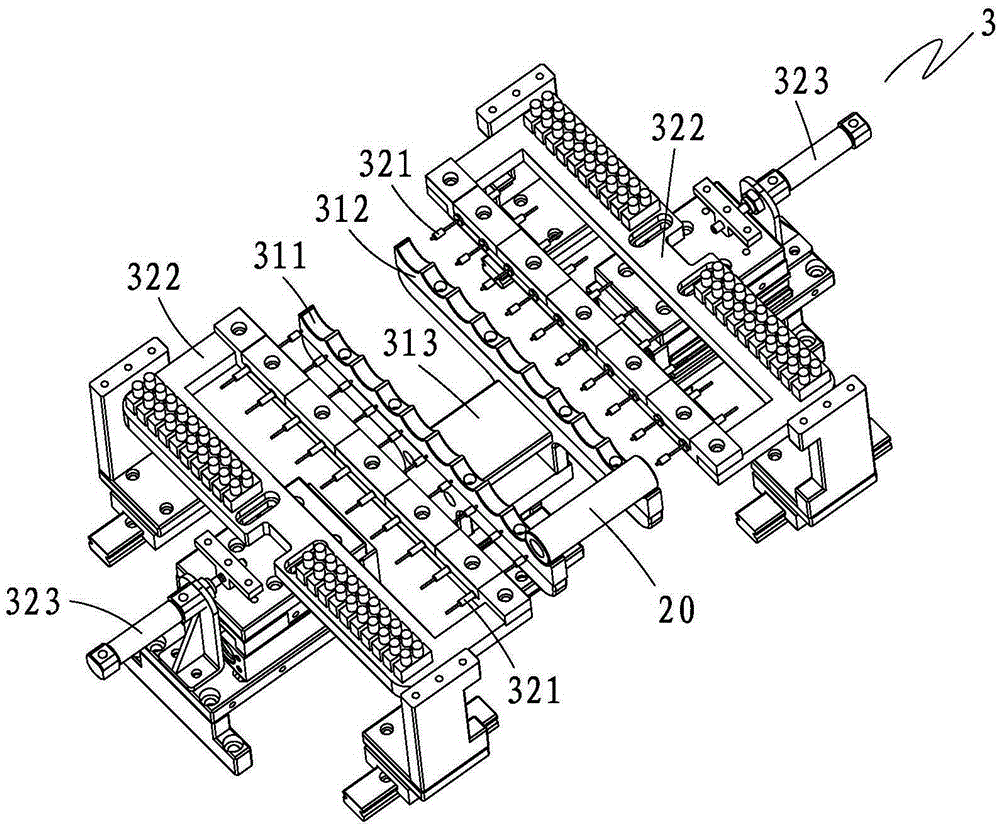

[0029] see Figure 1 to Figure 12 , the automatic sorting machine for lithium batteries of the present invention includes a control unit (not shown) and a feeding mechanism 1 electrically connected to the control unit, a coding scanning mechanism 2, a testing mechanism 3, a sorting mechanism 4, a discharge Mechanism 5 and delivery tank 6, the feeding mechanism 1 is located at the head end of the delivery tank 6, the testing mechanism 3 is set on the delivery tank 6, and the code scanning mechanism 2 is arranged on the side of the delivery tank 4 and is in the Between the material mechanism 1 and the testing mechanism 3, the discharge mechanism 5 and the testing mechanism 3 are arranged side by side, and the sorting mechanism 4 is erected above the testing mechanism 3 and the discharging mechanism 5, and the sorting mechanism 4 The lithium batteries 20 that have been tested on the testing mechanism 3 are sucked up correspondingly and placed on the corresponding receiving trough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com