Patents

Literature

65results about How to "The test process is stable and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water conveyance tunnel with prestressed composite lining for shield tunnelling

InactiveCN102191940AHigh degree of simulationLarge scale testUnderground chambersDrainageSocial benefitsReinforced concrete

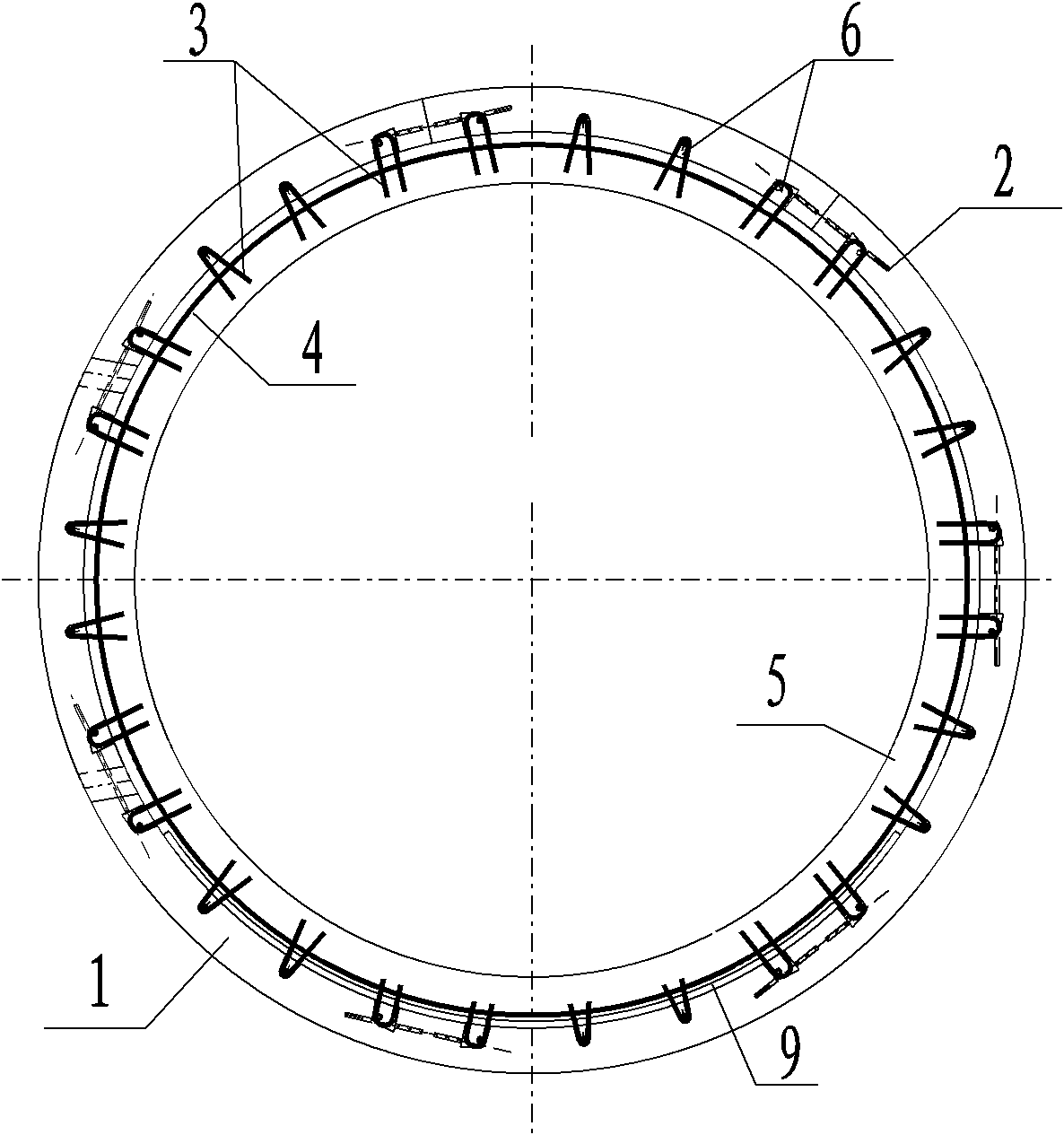

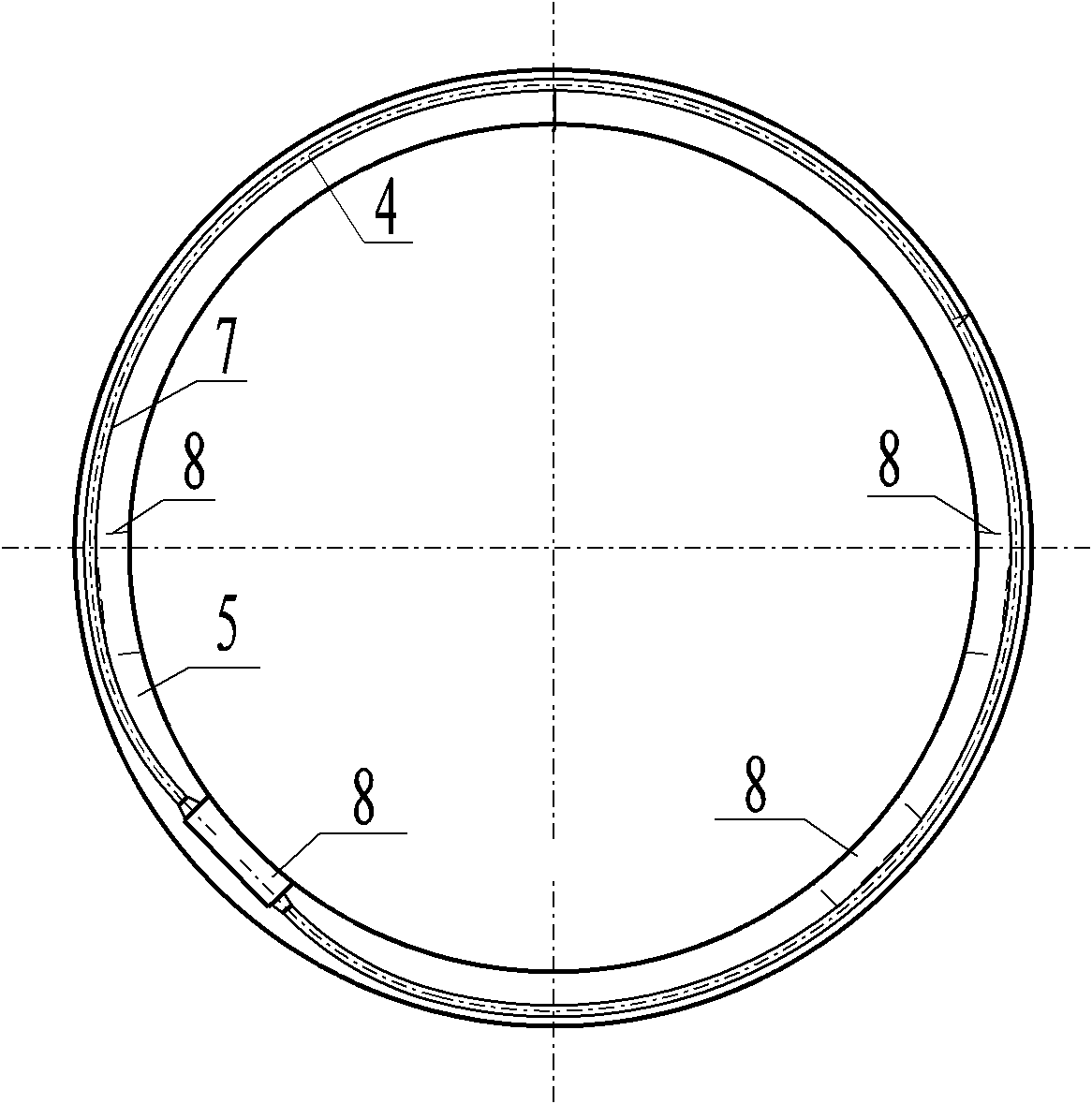

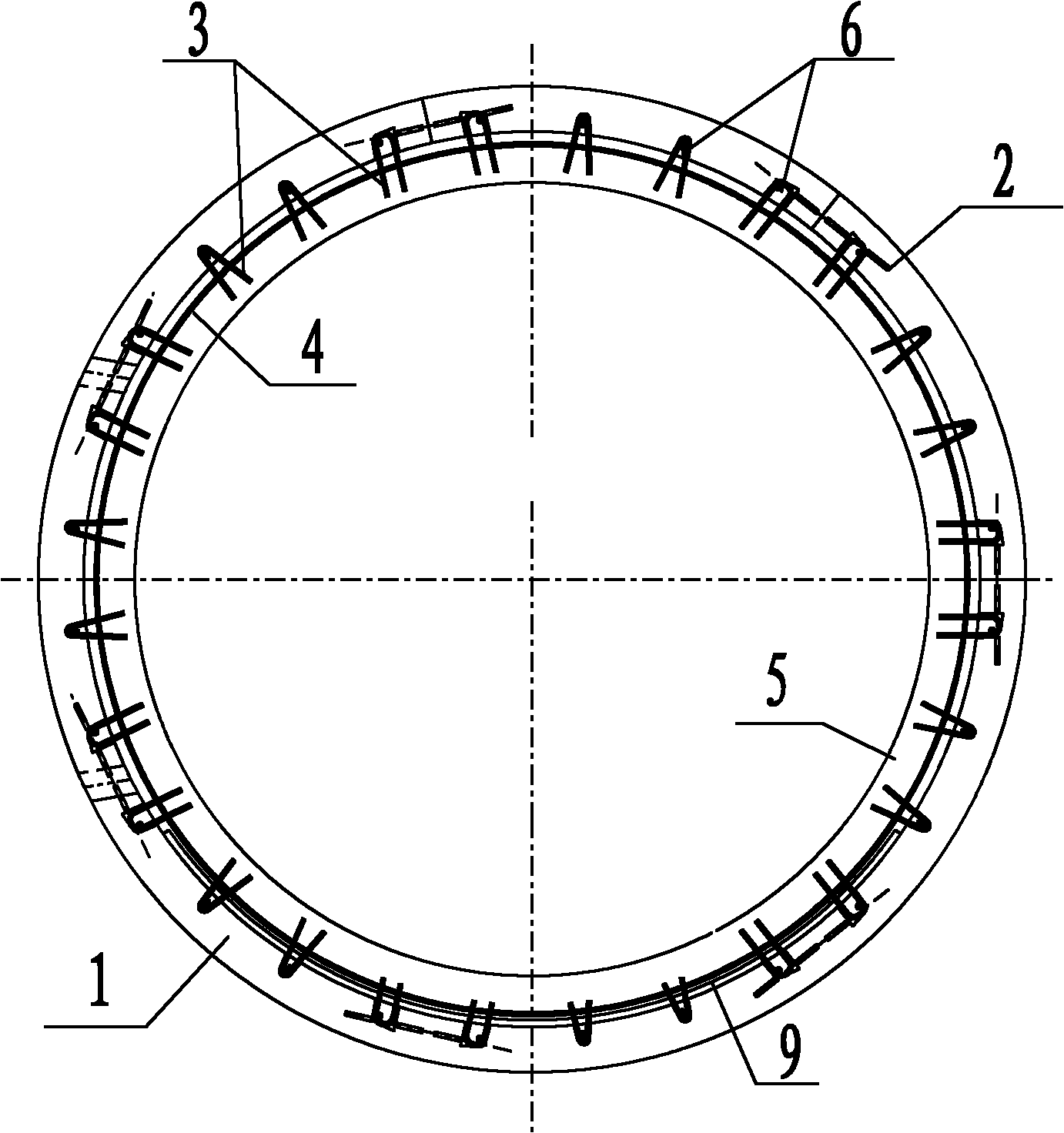

The invention provides a water conveyance tunnel with a prestressed composite lining for shield tunnelling. The tunnel comprises an ordinary reinforced concrete outer lining (1) which is formed by shield construction and is an assembled segment ring, wherein segments on the same ring are connected by connecting bolts (2); dowel bars (3) are installed in hand holes on the assembled segment ring; concrete is directly poured on the outer lining (1) to form an inner lining (5); shear keys (6) are formed in such a manner that concrete is filled in the hand holes of the outer lining; and the inner lining (5) and the outer lining (1) are combined via the dowel bars (3) and the concrete shear keys (6) to form a composite lining structure. Thus, the defects of great construction difficulty, long construction period and higher investment caused by the separated pressure pipeline water conveyance scheme for shield tunnelling are overcome. The technical problems of high head, high flow, high load and possibility of endangering the tunnel safety due to seepage of underground water, which are encountered when the soft soil layer of the riverbed is tunnelled in the shield tunnelling construction of the Yellow River crossing tunnel, are solved. Besides, the invention reduces the project investment and has obvious social benefits.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

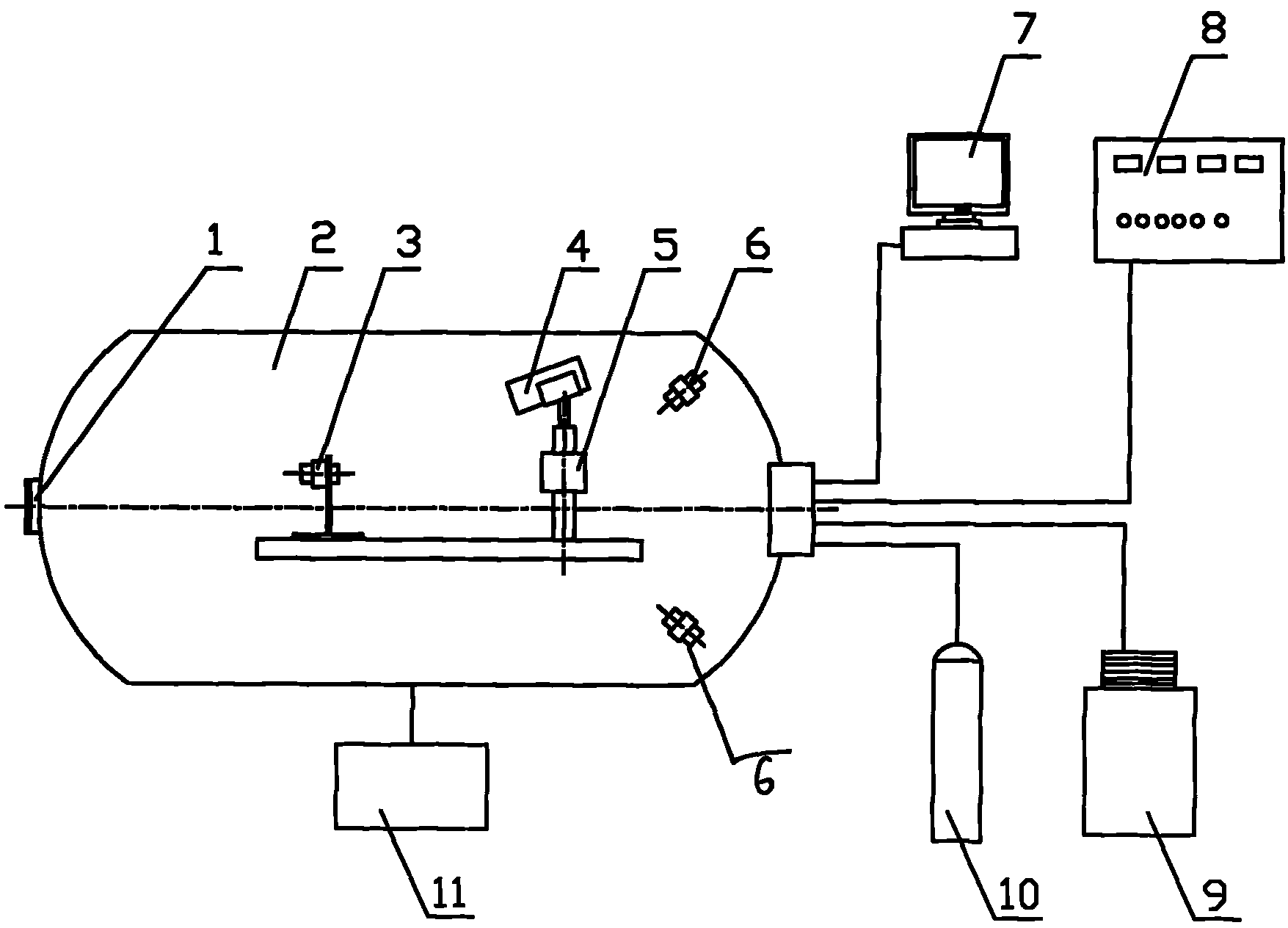

Method for monitoring plume contamination of attitude control engine of spacecraft

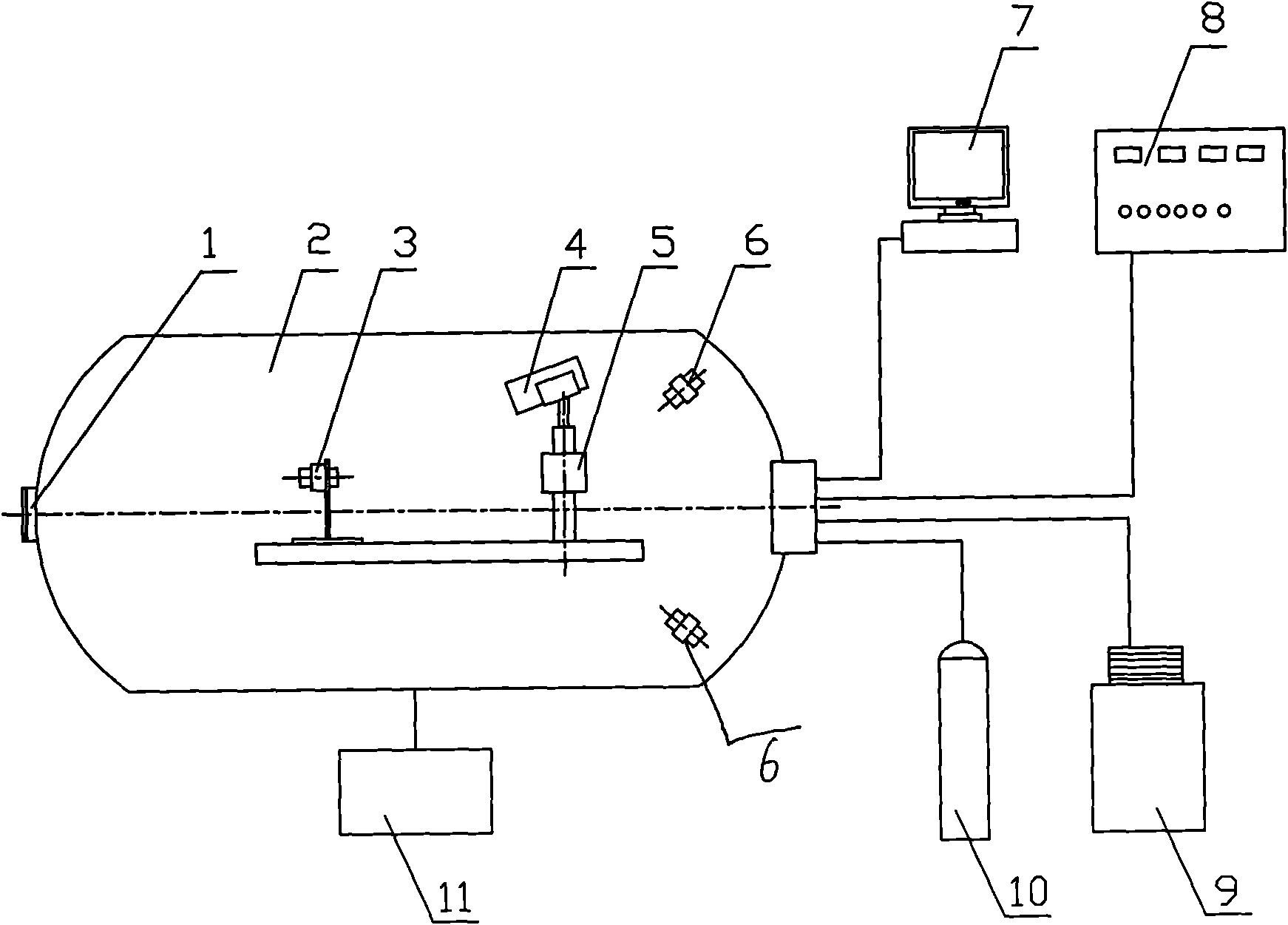

The invention relates to a method for monitoring plume contamination of an attitude control engine of a spacecraft, in particular to a method for monitoring plume contamination of an attitude control engine of a spacecraft by adopting a quartz-crystal microbalance, belonging to the technical field of aviation. In a monitoring device for the plume contamination of the attitude control engine of the spacecraft, a set of quartz-crystal microbalance monitor is arranged on the sliding rail of the existing space electric propulsion ground simulation testing equipment, and two sets of quartz-crystal microbalance monitors are arranged behind an engine nozzle on the surface of a vacuum chamber. In the method, an attitude engine is adopted to ignite so as to ensure that the engine jets heat flow gas, and contaminants are generated when the gas is condensed; and the frequency and temperature of the quartz-crystal microbalance are monitored online in situ and saved. The method improves the sensitivity of plume contamination monitoring of the attitude control engine in China reaching 1.10*10-9 to 4.42*10-9, and the testing process is stable and reliable and has good repeatability, so the method is suitable for large-scale tests.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

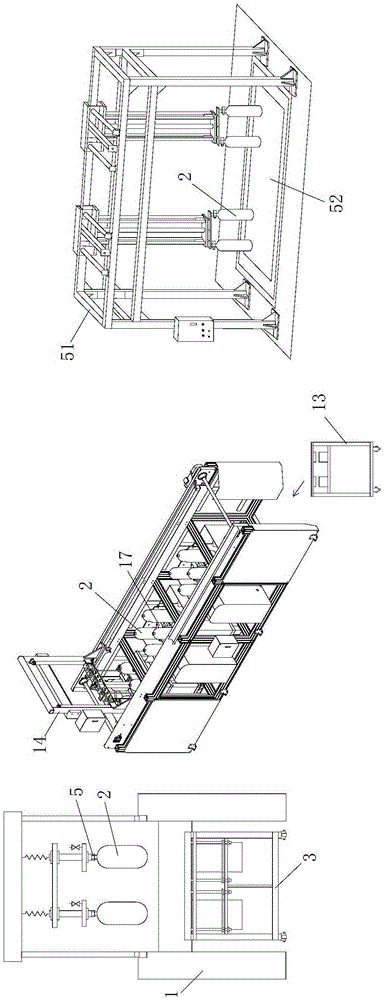

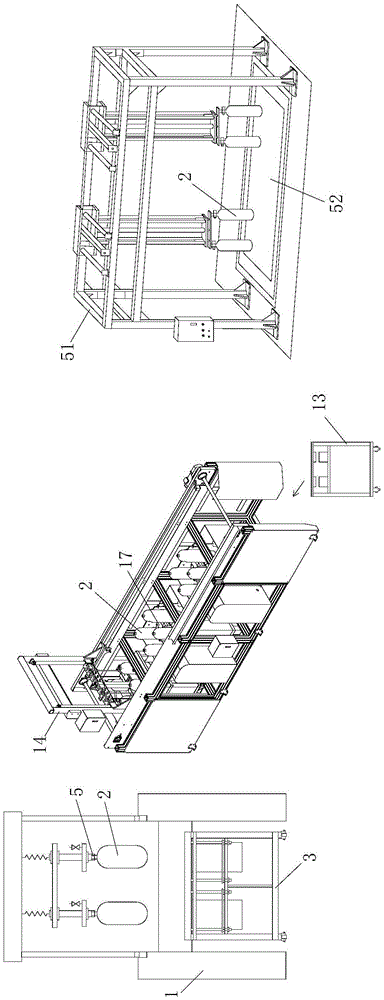

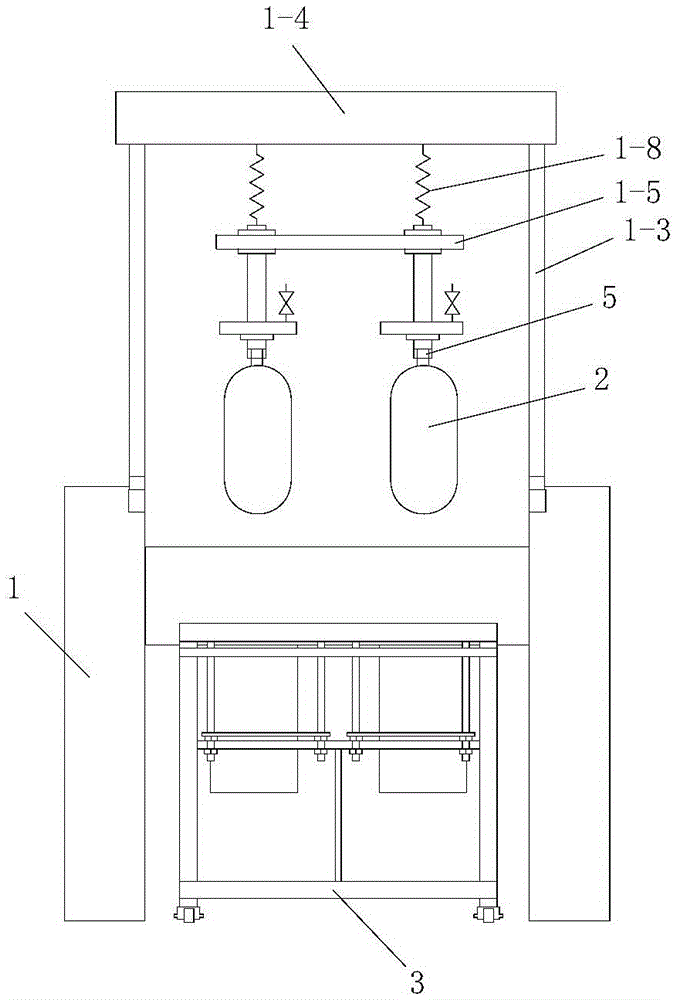

Carbon fiber gas cylinder detection line and carbon fiber gas cylinder detection method

InactiveCN105424489ASimple structureCompact structureDetection of fluid at leakage pointDrying using combination processesFiberCarbon fibers

The invention discloses a carbon fiber gas cylinder detection line and a carbon fiber gas cylinder detection method. The detection line includes, in a front-to-back arrangement manner, a water pressure test apparatus, a water pressure auxiliary test apparatus and an air tightness test apparatus. The water pressure test apparatus includes a test rack, a test operation bench, a pressurizing apparatus, a test case installed on the test rack, and test trolleys for stably placing a plurality of to-be-tested gas cylinders. The water pressure auxiliary test apparatus includes a gas cylinder fixture, a transporting trolley, and a gas cylinder water-pouring-away and drying device. The air tightness test apparatus includes an air tightness detection apparatus and a second air supply apparatus for supplying air to the to-be-tested gas cylinders. The air tightness test apparatus is in a cabinet structure or a ground trough structure. The detection method includes the steps of 1) water pressure test; 2) water pouring-away and drying treatment; and 3) air tightness test. The detection line is reasonable in design and simple in operations, is good in use effects, and can easily and quickly complete water pressure test and air tightness test for a plurality of carbon fiber gas cylinders.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

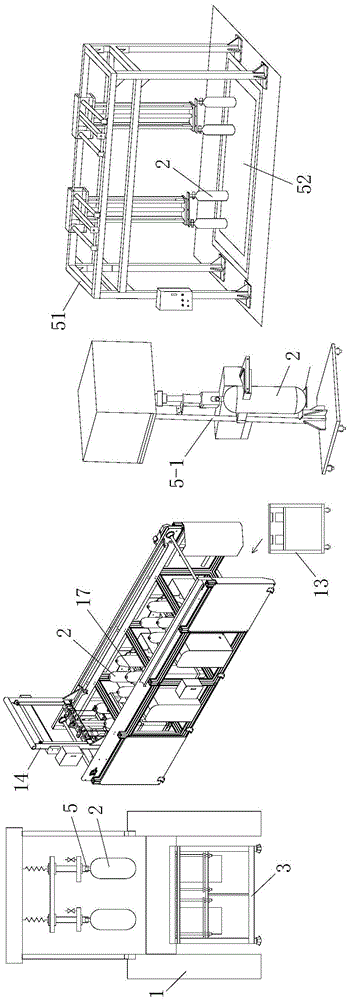

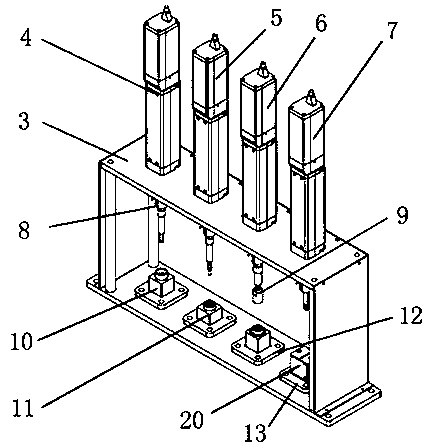

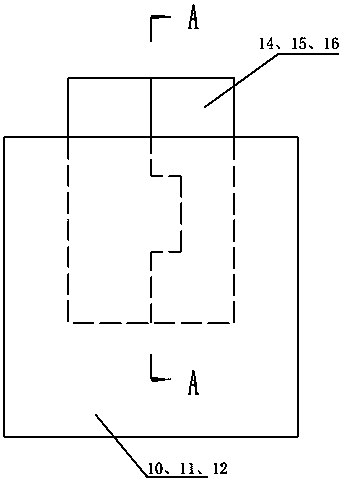

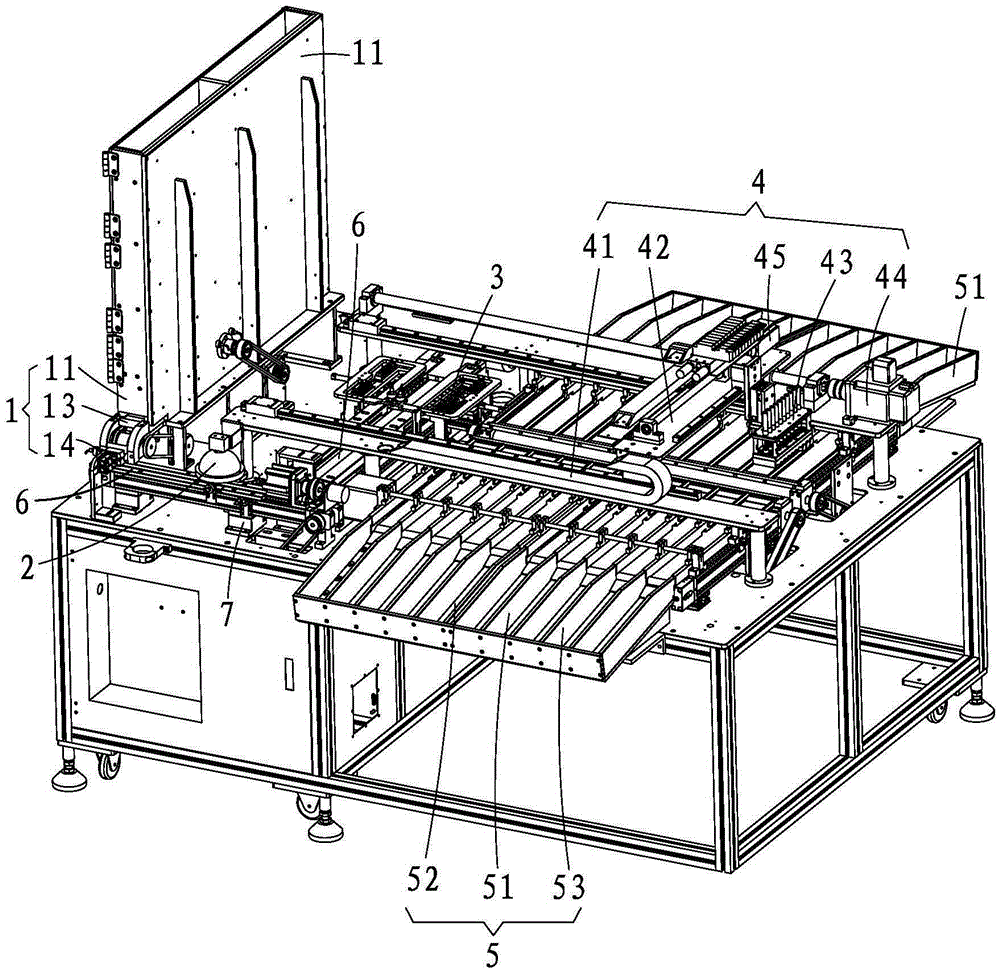

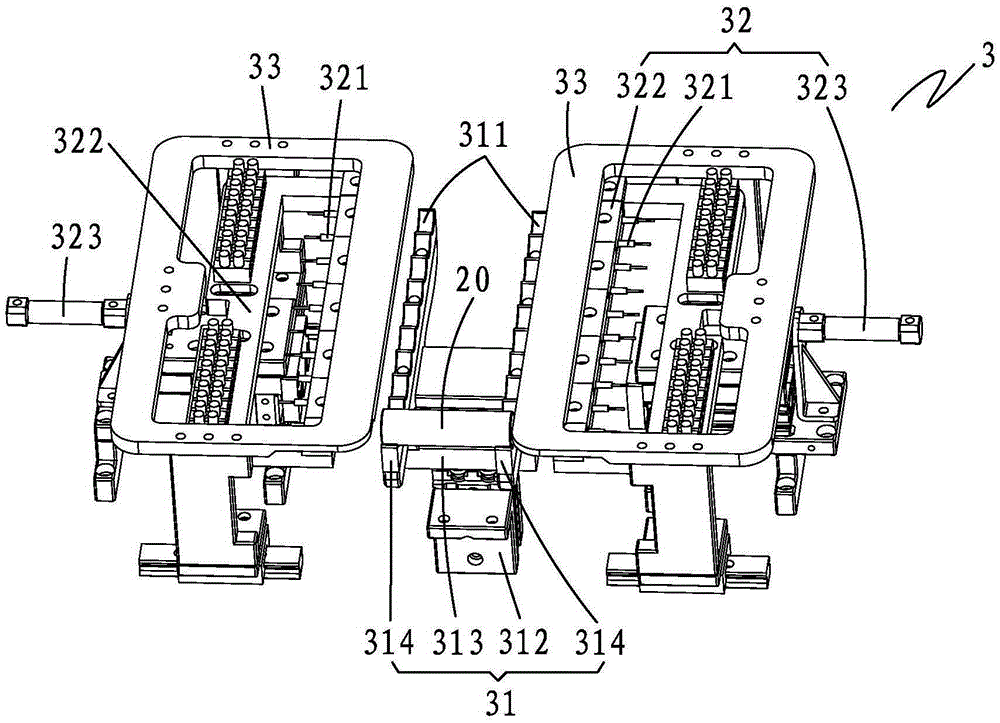

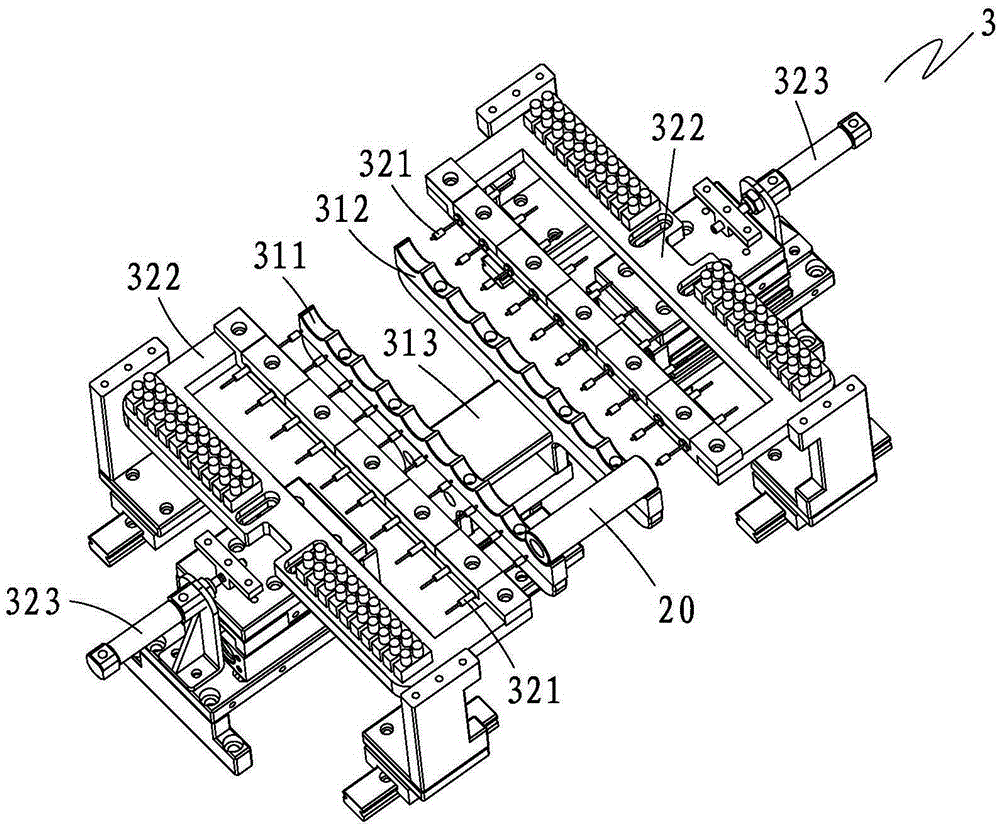

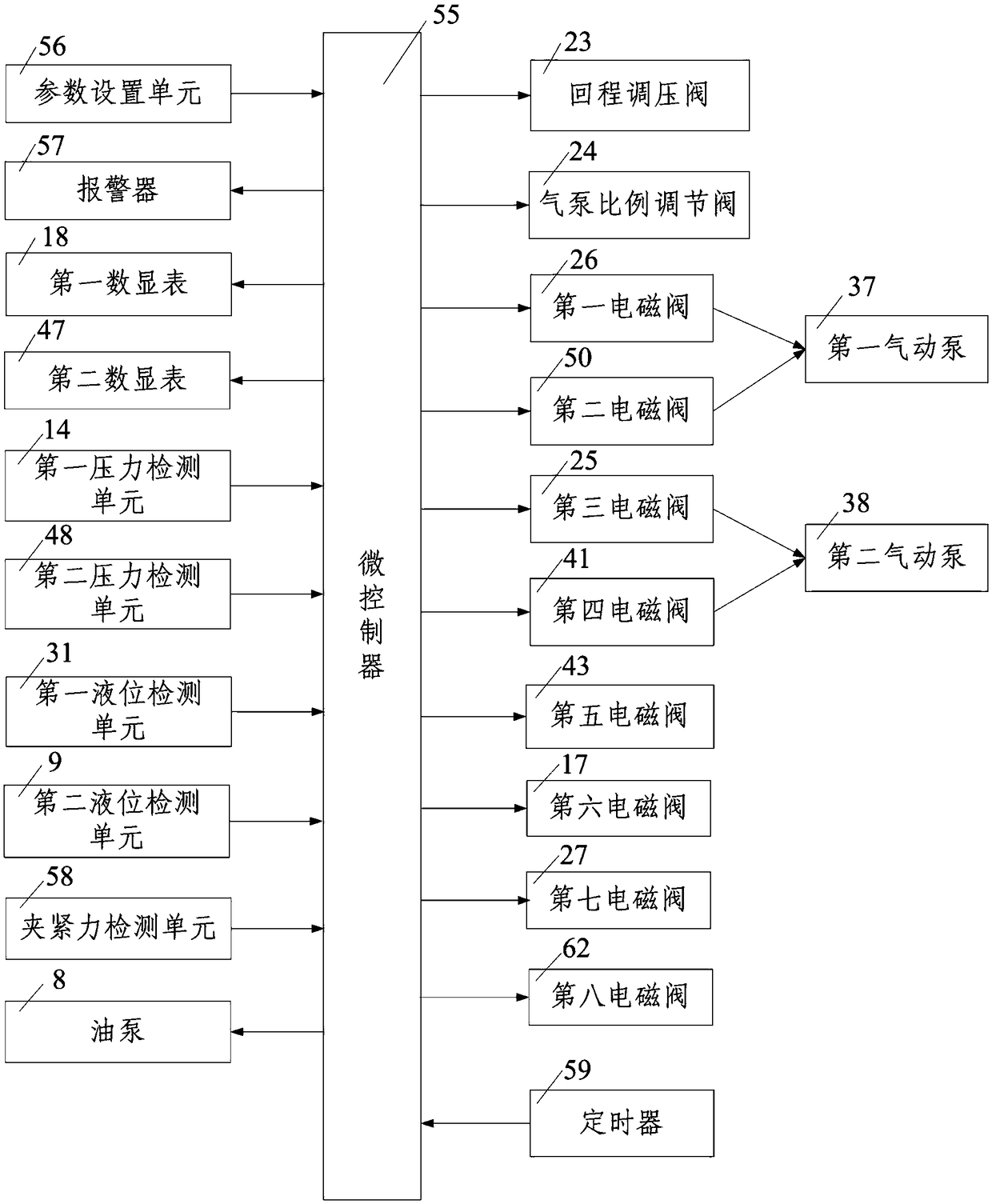

Automatic detection line and detection method of carbon fiber gas bottle

InactiveCN105466786ASimple structureCompact structureDetection of fluid at leakage pointDrying using combination processesEngineeringTest fixture

The invention discloses an automatic detection line and detection method of a carbon fiber gas bottle. The detection line comprises a water pressure testing device, an auxiliary water pressure testing device, a bottle valve loading and unloading machine and an air tightness experiment device, which are arranged from front to back, wherein the water pressure testing device comprises a testing rack, a testing operation platform, a pressurizing device, a testing box and a testing trolley; the auxiliary water pressure testing device comprises a gas bottle clamp, a conveying trolley, and gas bottle water pouring and drying treatment equipment; the bottle valve loading and unloading machine comprises a bottle valve loading and unloading rack, a control cabinet, a gas bottle fixing mechanism and a bottle valve screwing mechanism; the air tightness experiment device comprises an air tightness testing device and a second gas supplying device for supplying gas to a plurality of gas bottles to be tested. The detection method comprises the following steps: 1, testing water pressure; 2, carrying out water pouring and drying treatment; 3, assembling a bottle valve; 4, testing air tightness. The automatic detection line provided by the invention is reasonable in design, simple to use and operate and good in use effect, and can be used for simply, conveniently and rapidly finishing water pressure testing and air tightness testing processes of the plurality of carbon fiber gas bottles.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

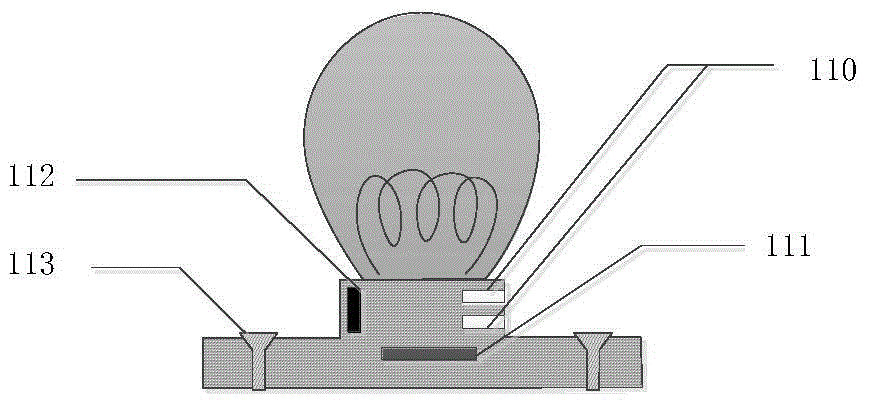

Calibration method of quartz crystal microbalance

ActiveCN101750140AHigh sensitivityImprove accuracyWeighing apparatus testing/calibrationQuartz crystal microbalanceTest procedures

The invention relates to a calibration method of a quartz crystal microbalance, belonging to the technical field of aeronautics and astronautics. The method comprises depositing heavy metal gold at the surface of the quartz crystal microbalance by using a magnetron sputtering device; injecting an inert gas in a vacuum system; observing and recording the vacuum degree of a vacuum chamber; monitoring and storing the frequency value and the temperature value of the quartz crystal microbalance; monitoring and storing the S polarized light current and P polarized light current of ellipsometry system, and finally closing the testing system, closing the gas charging system of inert gas, and closing the vacuum system. The method improves the sensibility of precision measurement of the quartz crystal microbalance; the test procedure is stable and reliable, and has good replicability; an ellipsometry film thickness measuring apparatus is used for providing direct film thickness measuring method for the quartz crystal microbalance; and the method has high measuring accuracy, stable test procedure and good replicability.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

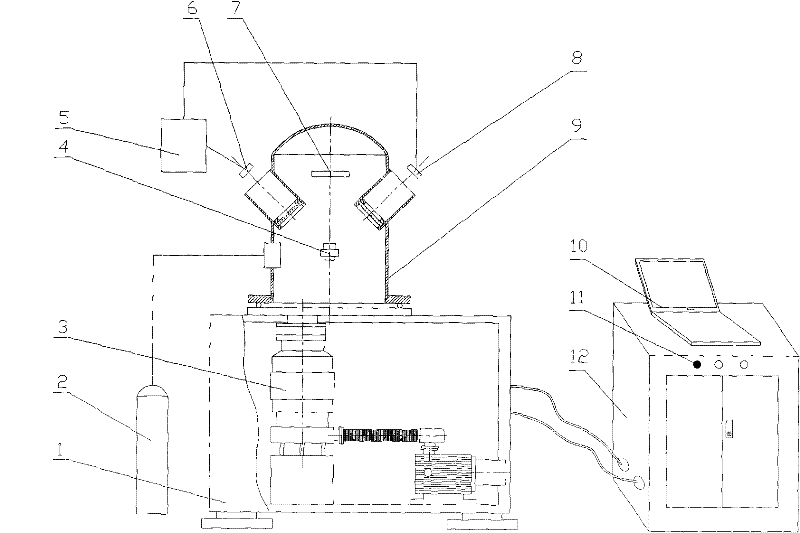

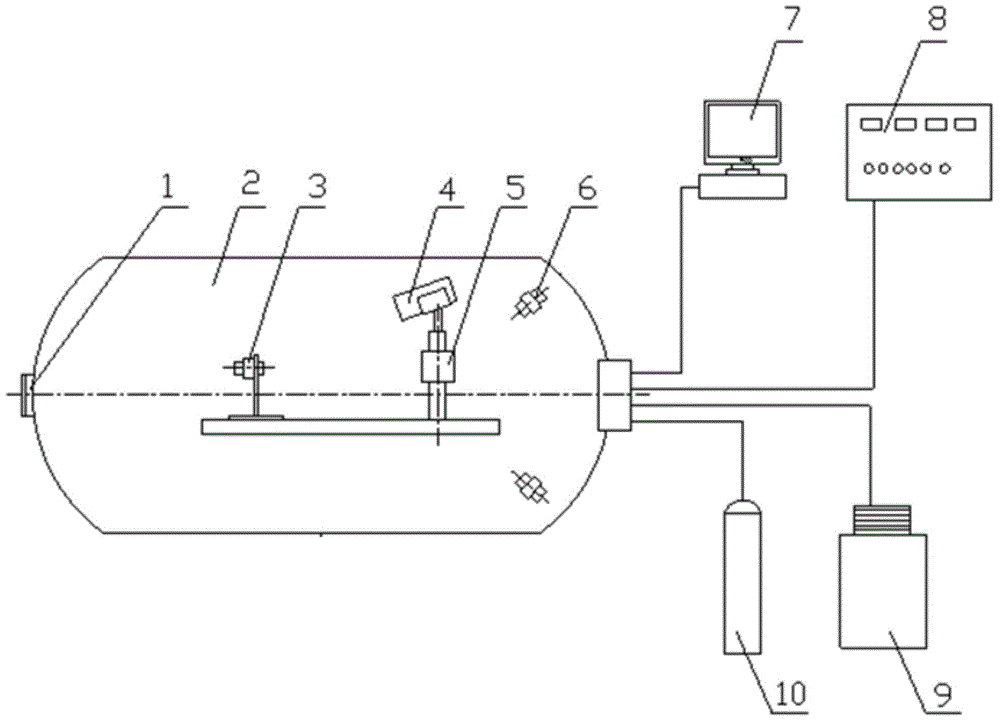

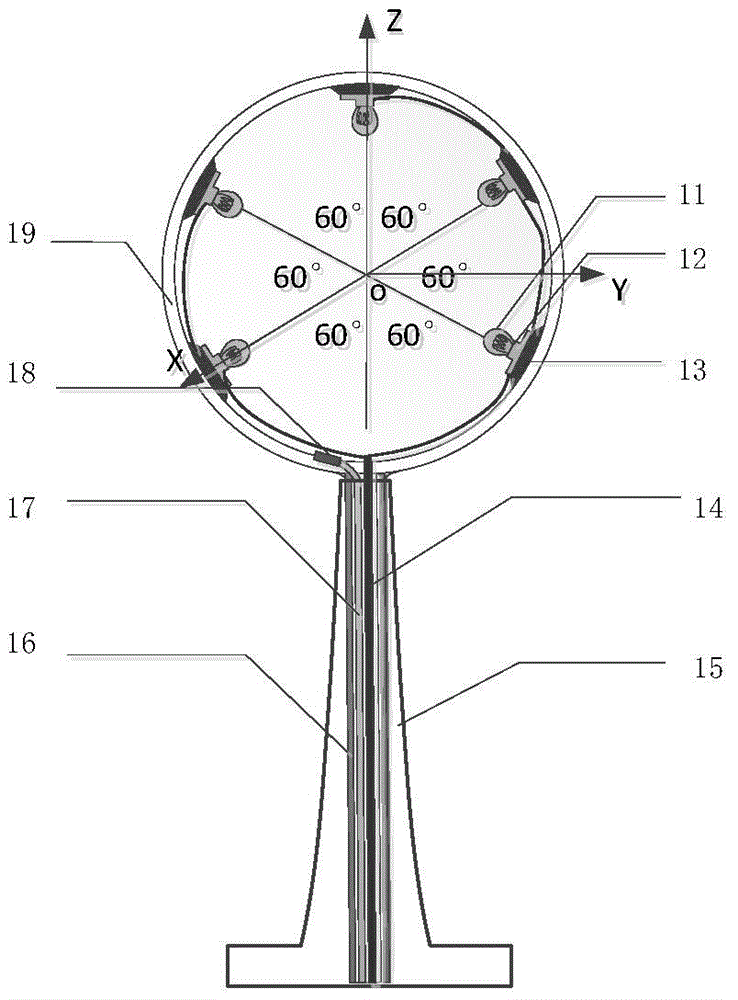

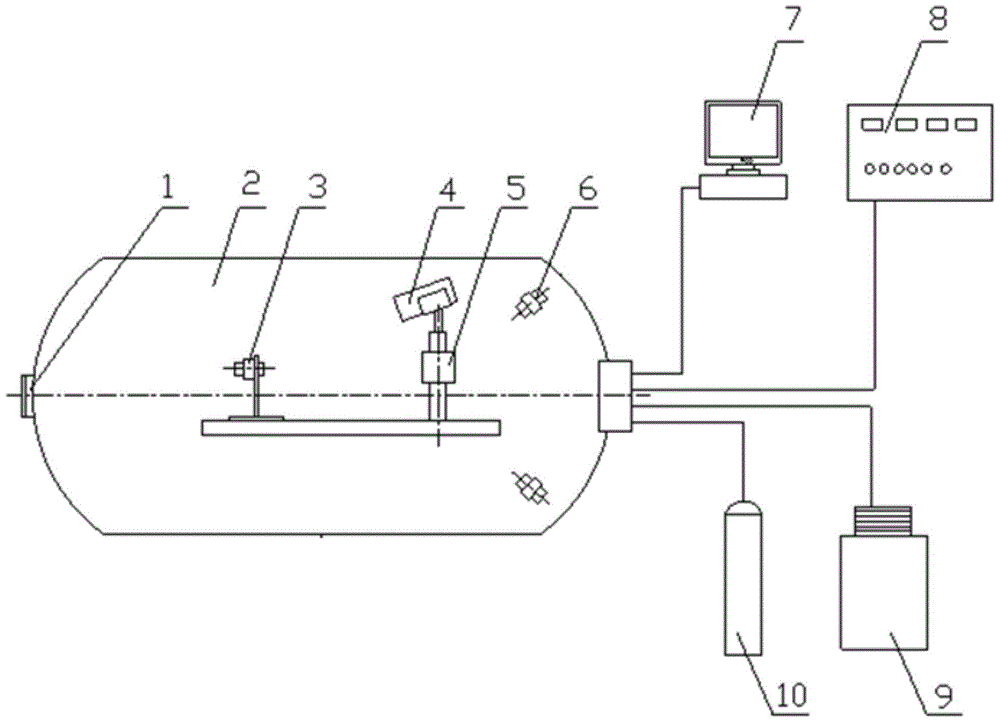

Electric propulsion spacecraft plume parameter detection apparatus

ActiveCN105004529AHigh sensitivityImprove accuracyGas-turbine engine testingJet-propulsion engine testingElectricitySpace environment

The invention provides an electric propulsion spacecraft plume parameter detection apparatus. The apparatus comprises a vacuum cabin observation window, a vacuum cabin, two electric thruster multi-parameter diagnosis devices, an electric thruster, a movable support, a computer, an ignition control cabinet, a vacuum air exhaust system, and an air supply bottle, the radial cross section of a first electric thruster multi-parameter diagnosis device vertical to an installing plate is parallel to the radial cross section of the electric thruster vertical to the installing plate, and the distance between the two radial cross sections is greater than 100 cm. According to the apparatus, the electric propulsion spacecraft plasma plume parameter distribution and spacecraft on-orbit performance degradation condition in the simulated space environment condition can be estimated via the measurement and collection of pollution data in the electric thruster multi-parameter diagnosis devices, guidance and basis are provided for the development of the electric propulsion spacecraft and the estimation of the lifetime, the electric propulsion spacecraft can work safely and reliably in the space, the test process is stable and reliable, and the reproducibility is good.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Method for monitoring sensitive low-temperature surface pollution of spacecrafts

ActiveCN101876613AHigh sensitivityReduce risks in materials usedMaterial weighingMetallic materialsEngineering

The invention relates to a method for monitoring sensitive low-temperature surface pollution of spacecrafts, in particular to a method for monitoring sensitive low-temperature surface pollution of spacecrafts by utilizing a quartz crystal microbalance, belonging to the technical field of aerospace. The method is directly applied to monitoring surface pollution of infrared low-temperature remote sensors and other low-temperature space probes. The method is characterized by utilizing a liquid nitrogen refrigeration system and quartz wafers to simulate the sensitive low-temperature surfaces of the spacecrafts; lowering the surface temperature of the quartz crystal by the liquid nitrogen refrigeration system to ensure the quartz crystal to work under the worst temperature on the spacecraft orbit; heating non-metal materials or ensuring an engine to ignite to ensure the non-metal materials or the engine to effuse or jet pollutants; carrying out online in-situ monitoring on the frequency and temperature of the quartz crystal microbalance and storing the frequency and temperature; and closing a test system. The method is high in sensitivity (1.10*10<-9>-4.42*10<-9>), stable and reliable in test process, good in repeatability and suitable for large-scale test.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

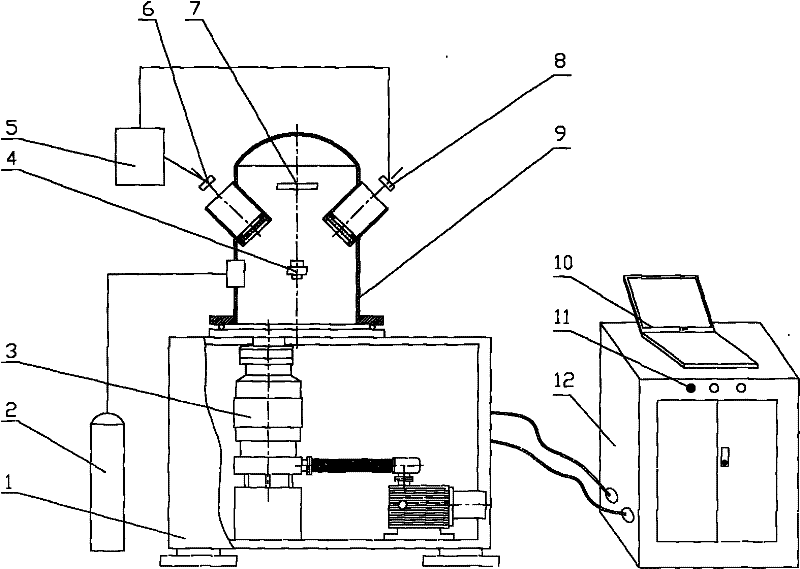

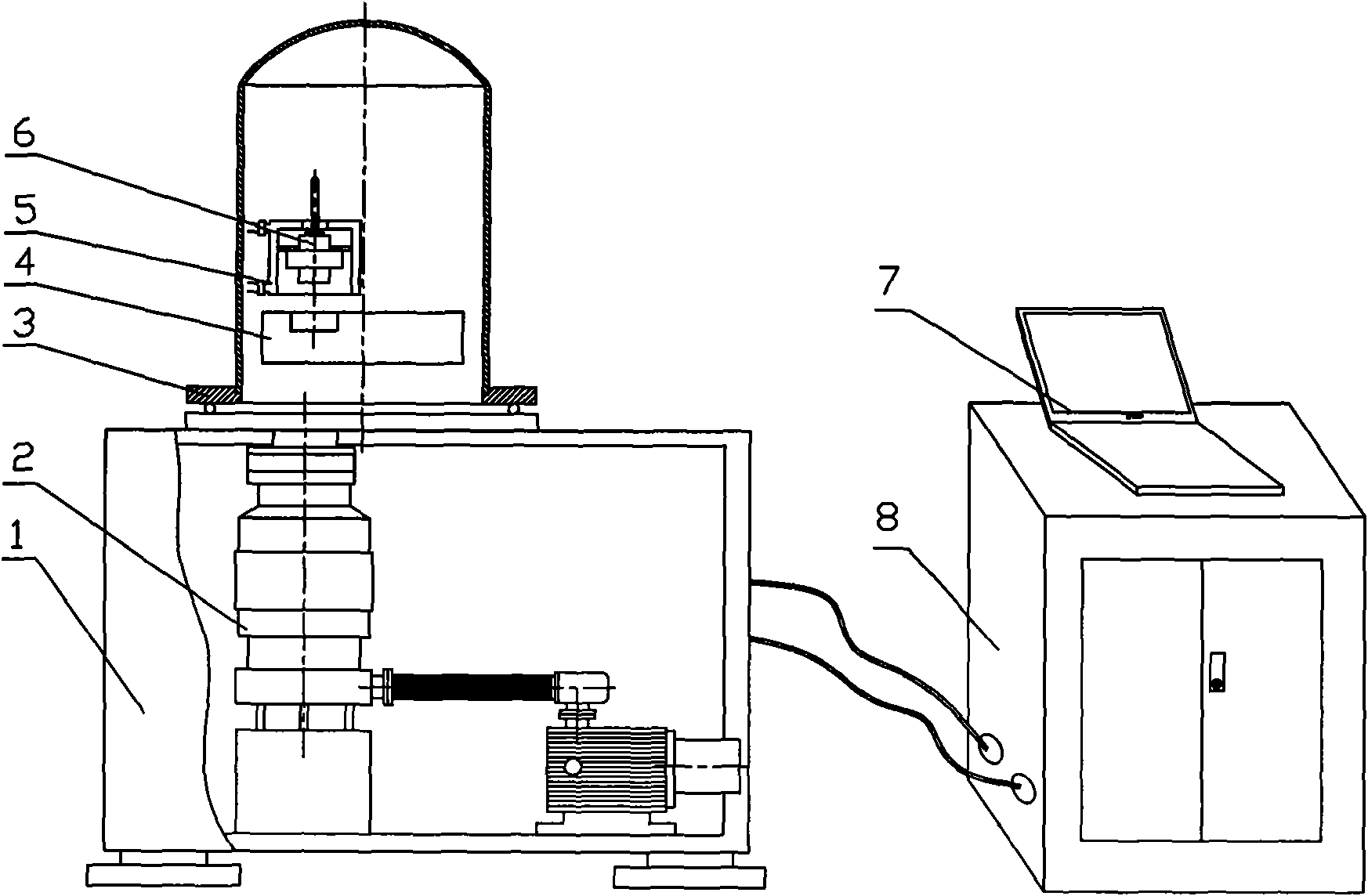

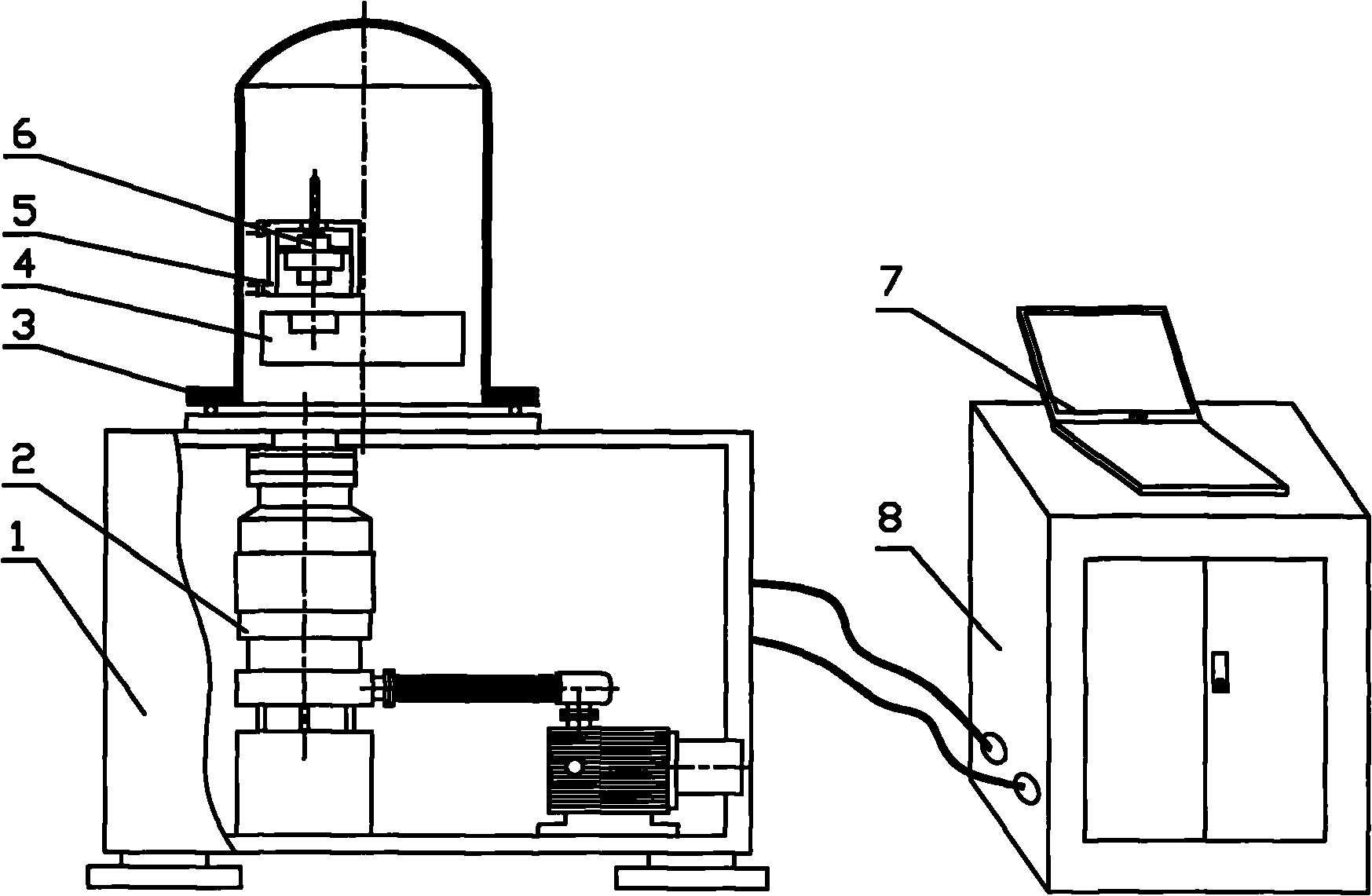

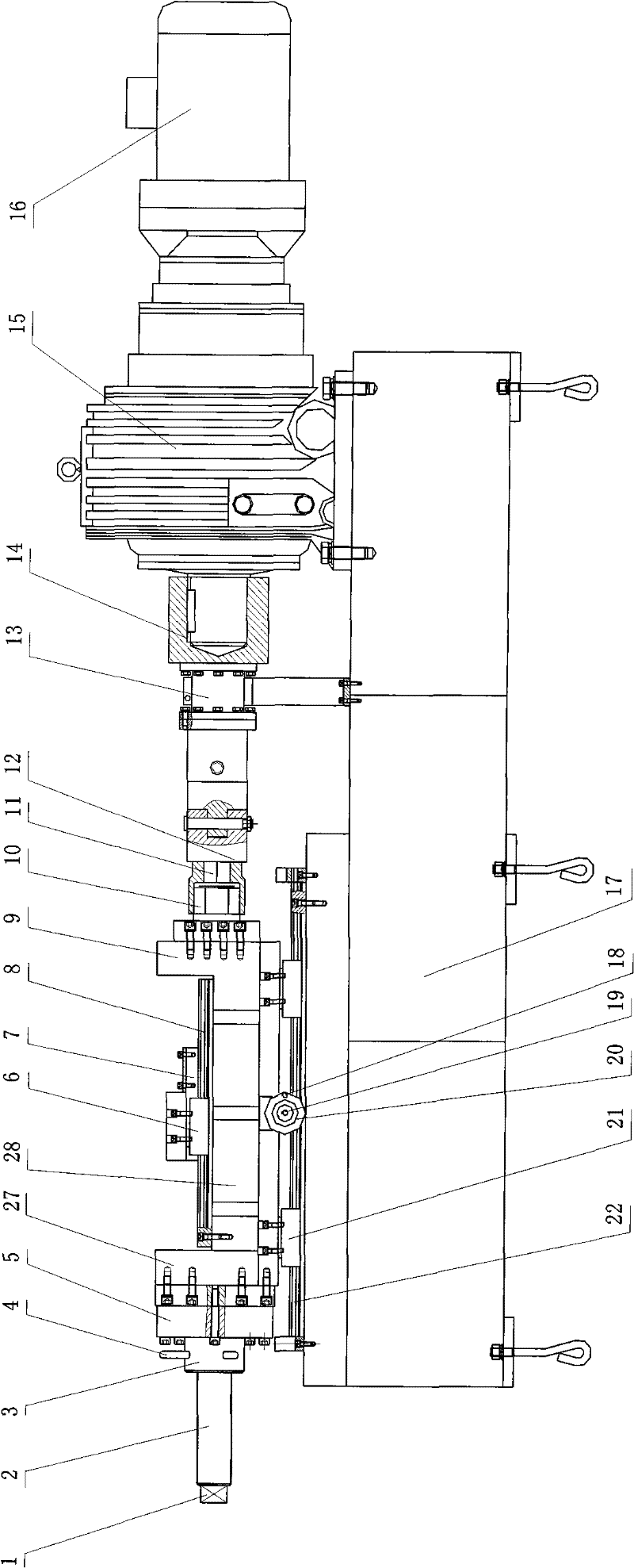

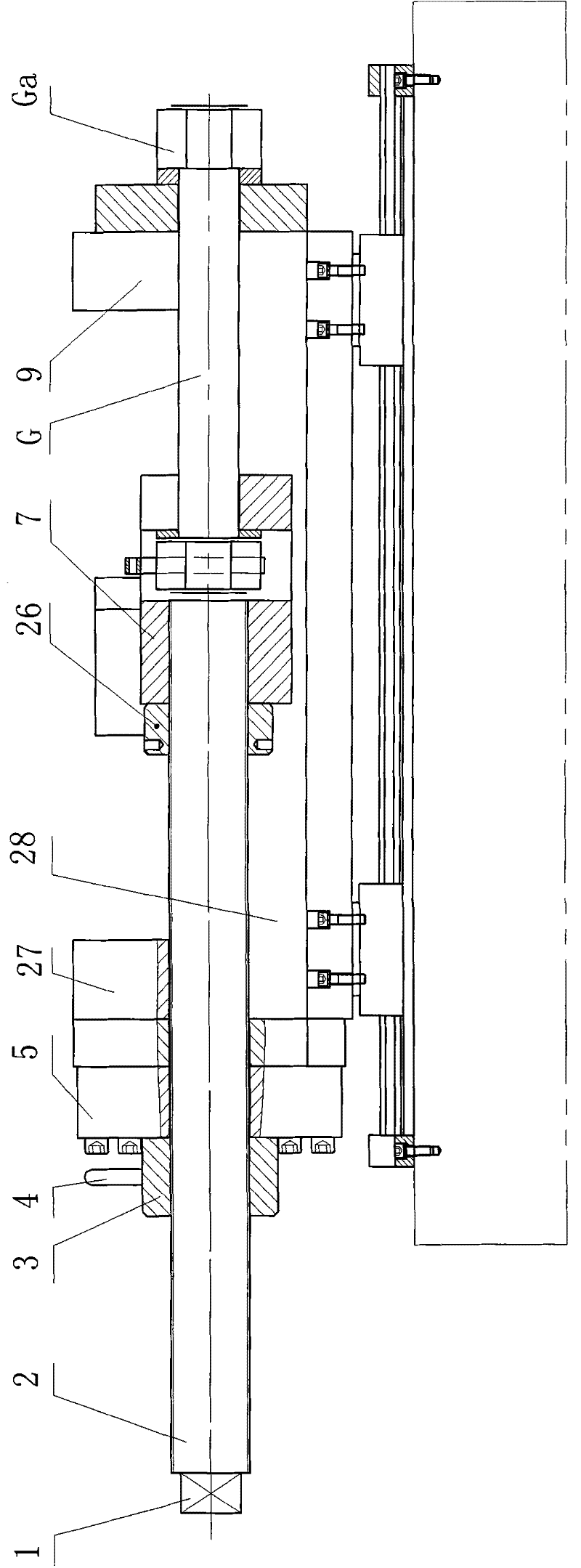

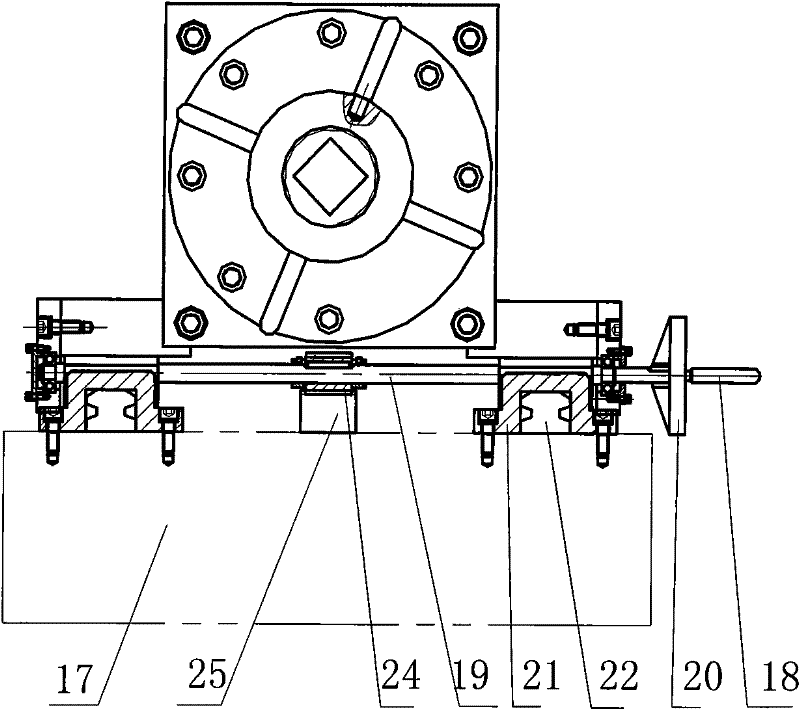

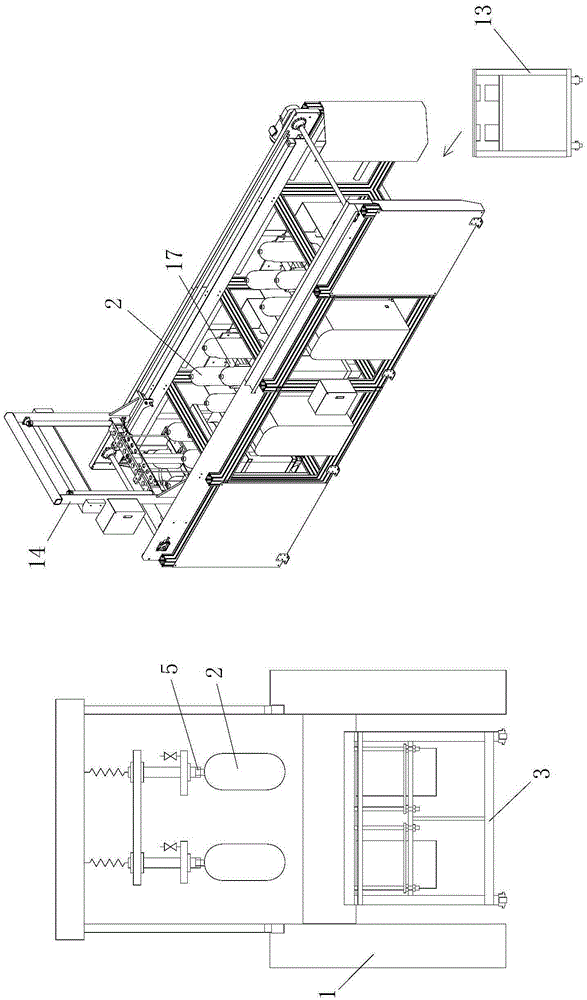

A large-scale bolt torque testing equipment

ActiveCN102262021ARealize fully automatic collectionRealize the display effectMaterial strength using steady torsional forcesCouplingElectric machinery

The invention belongs to experimental and testing devices for mechanical parts, and specifically relates to a torque force testing device for a large-sized bolt. The device comprises a clamping and fixing part and a twisting part; the clamping and fixing part is formed by the way that two guide rails (22) are arranged on a pedestal (17), left and right guide sleeves (21) are arranged on each guide rail (22), a sliding pull base (28) is formed on the four guide sleeves (21), a bolt pull sleeve (7) is placed in an opening cavity of the sliding pull base (28), and two sides of the bolt pull sleeve (7) are sleeved in sliding rails (8) at two sides of the opening cavity of the sliding pull base (28) via sliding sleeves (6); a front end of a tensioning screw (2) is connected with the bolt pull sleeve (7); a locking screw disc (3) is sleeved on the tensioning screw (2); a rack (25) is arranged on the pedestal (17); and a shaft (19) of a wheel gear (24) engaged with the rack penetrates into the sliding pull base (28). The twisting part is orderly composed of a nut sleeve head (10), a rotary special-shaped head (11), a universal coupling (12), a torque sensor (13), a coupling (14), a reducer (15) and a motor (16). The torque force testing device is steady, reliable, accurate, safe and convenient in the test procedure, and can implement automatic test and improve the speed, the efficiency and the accuracy of the test.

Owner:上海宝冶工程技术有限公司 +1

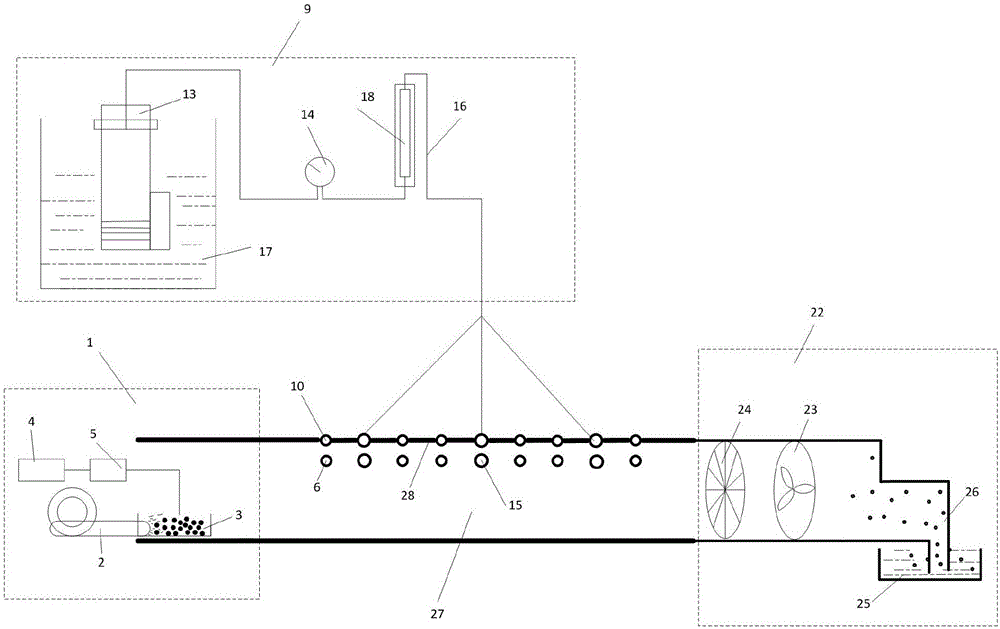

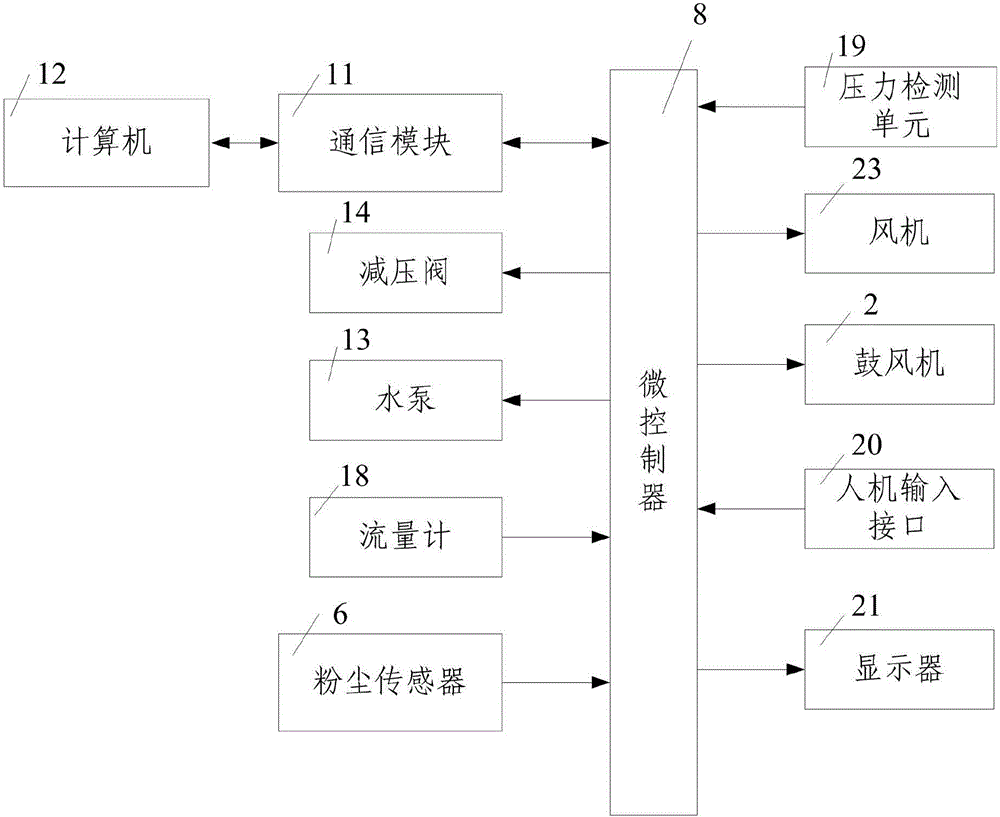

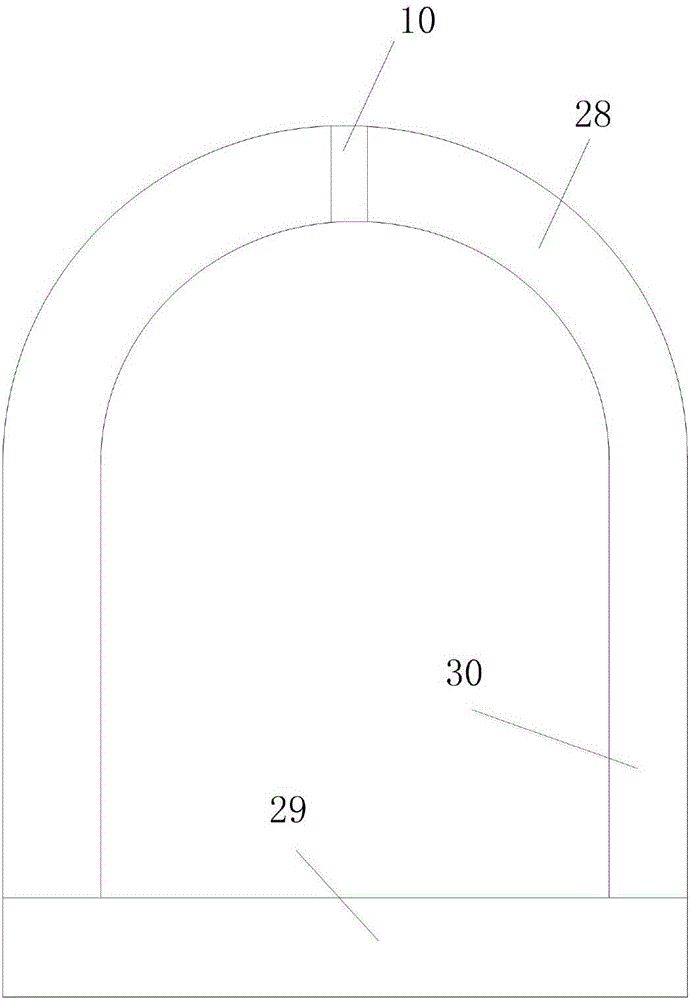

Testing device and testing method for dust removing effect of dust suppressant and dust preventive

ActiveCN106769742ASimple structureReasonable designParticle suspension analysisEngineeringData treatment

The invention discloses a testing device and a testing method for the dust removing effect of a dust suppressant and a dust preventive. The testing device comprises a data collecting and processing device, a simulated roadway device, a dust generation device, a dust preventive spraying device and a dust removing device. The testing method comprises the following steps: 1, preparing dust which is not soaked in a dust suppressant solution; 2, preparing dust which is soaked in the dust suppressant solution; 3, measuring the air dust concentration in a simulated roadway; 4, conveying the dust which is not soaked in the dust suppressant solution and measuring the dust concentration in the simulated roadway; 5, starting the dust preventive spraying device while conveying the dust which is not soaked in the dust suppressant solution, and measuring the dust concentration in the simulated roadway; 6, conveying the dust which is soaked in the dust suppressant solution and measuring the dust concentration in the simulated roadway; 7, starting the dust preventive spraying device while conveying the dust which is soaked in the dust suppressant solution, and measuring the dust concentration in the simulated roadway; 8, processing data and obtaining the dust removing efficiency. The testing device and the testing method, disclosed by the invention, are capable of testing the dust removing effect of the dust suppressant and the dust preventive.

Owner:XIAN UNIV OF SCI & TECH +1

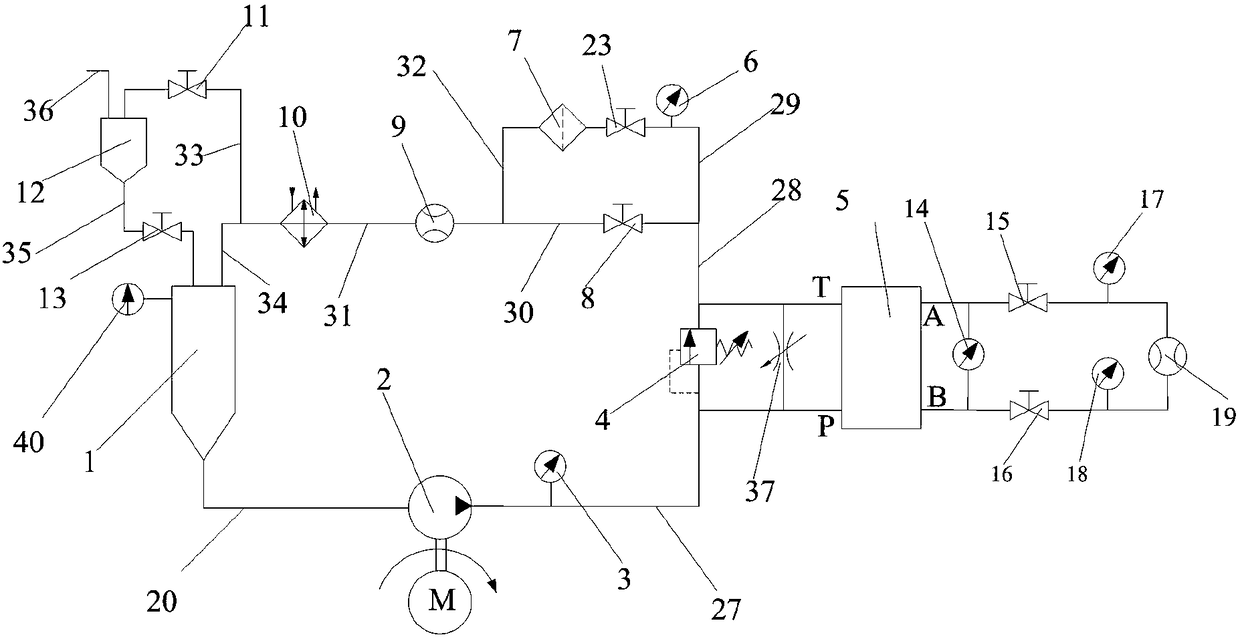

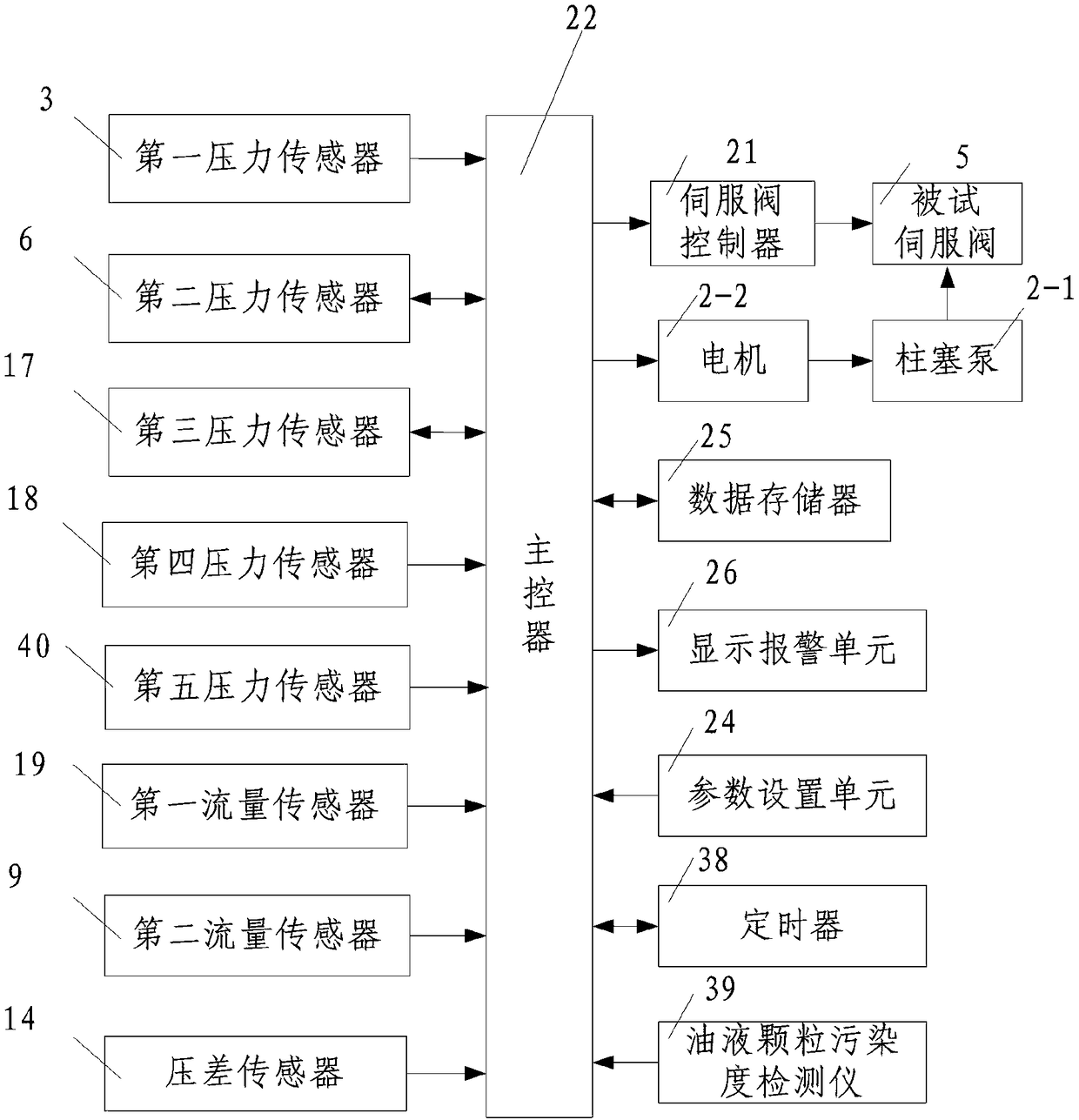

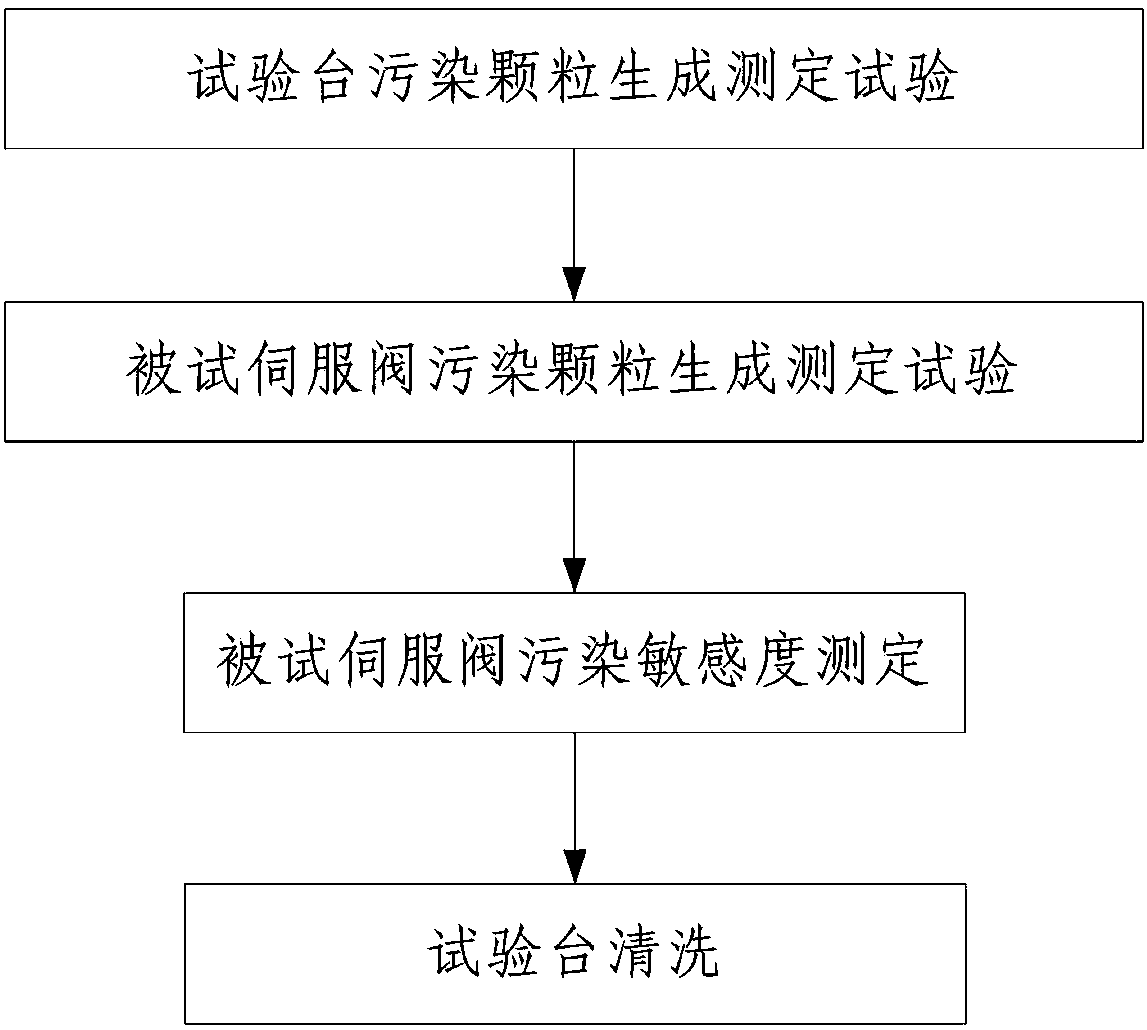

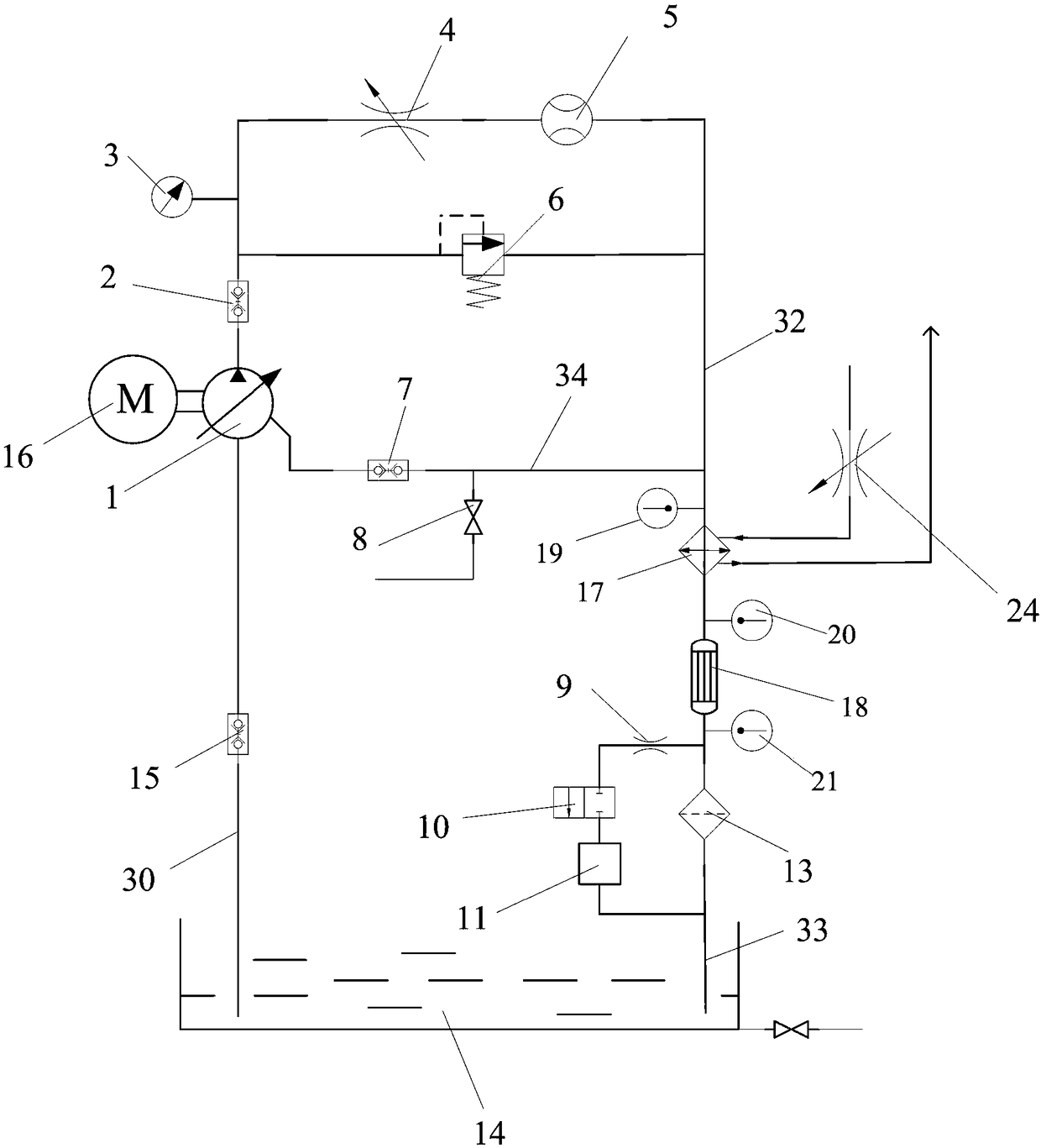

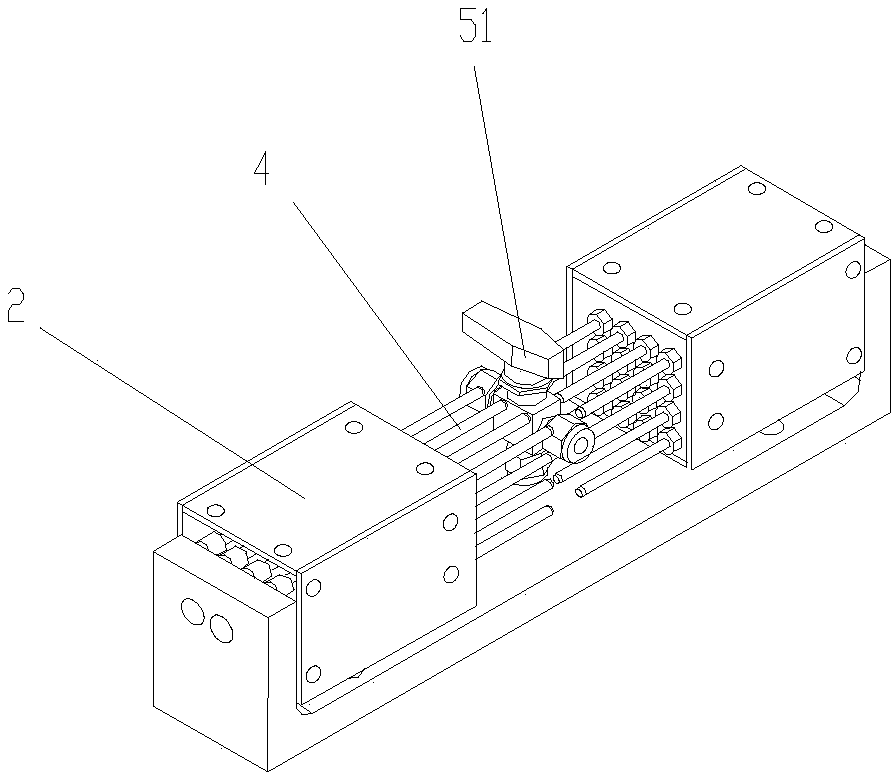

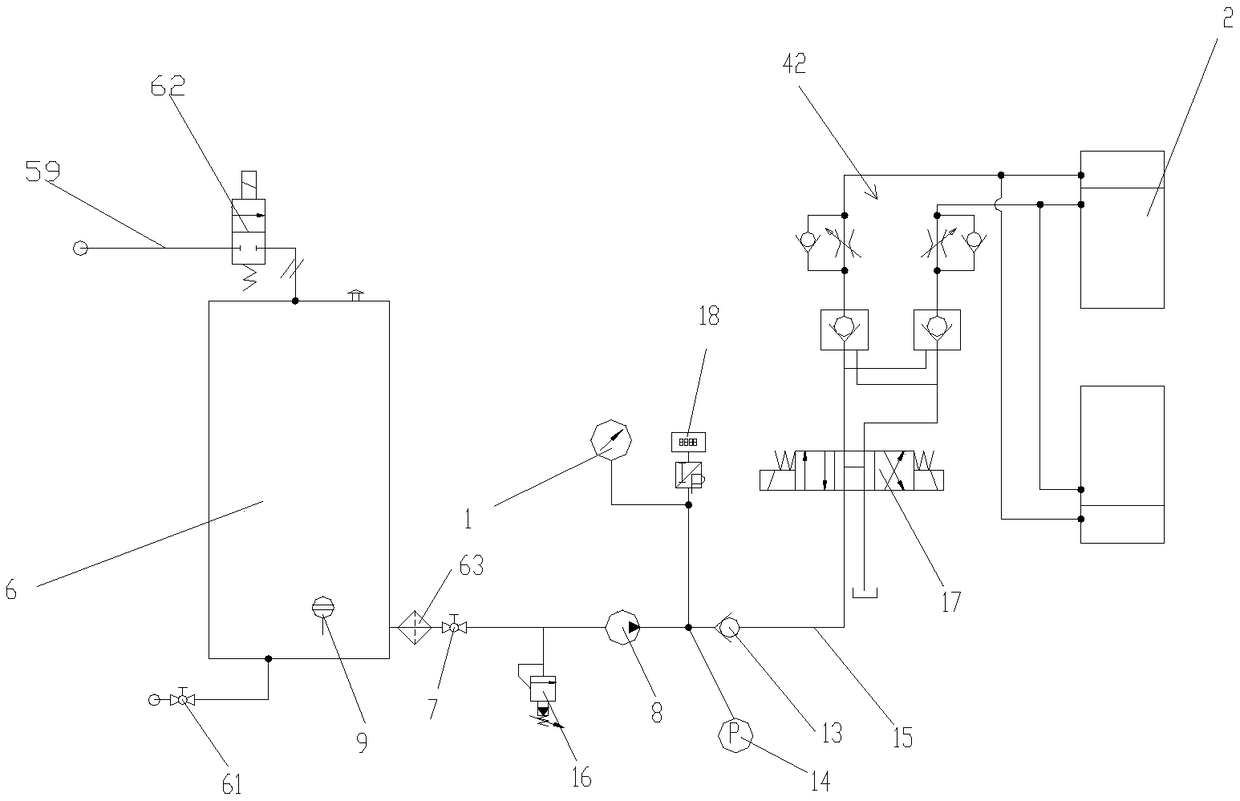

Testing device and testing method for servo valve pollution sensitivity measurement

ActiveCN108169091ASimple structureReasonable designParticle suspension analysisMeasurement testControl theory

The invention discloses a testing device and a testing method for servo valve pollution sensitivity measurement. The testing device comprises a monitoring device and a test bench for mounting a testedservo valve, wherein the test bench comprises an oil supply device for supplying oil to the tested servo valve, a cleaning filter for filtering hydraulic oil at an oil returning port of the tested servo valve, and a dust solution tank for collecting the hydraulic oil at the oil returning port of the tested servo valve and accommodating a dust solution. The testing method comprises the following steps: 1, performing a test bench pollution particle generation measurement test; 2, performing a tested servo valve pollution particle generation measurement test; 3, performing tested servo valve pollution sensitivity measurement; 4, cleaning the test bench. The testing device is reasonable in design, easy and convenient to use and operate and good in using effect; measurement of servo valve pollution sensitivity can be easily, conveniently and quickly completed; the testing precision is relatively high.

Owner:陕西东方长安航空科技有限公司

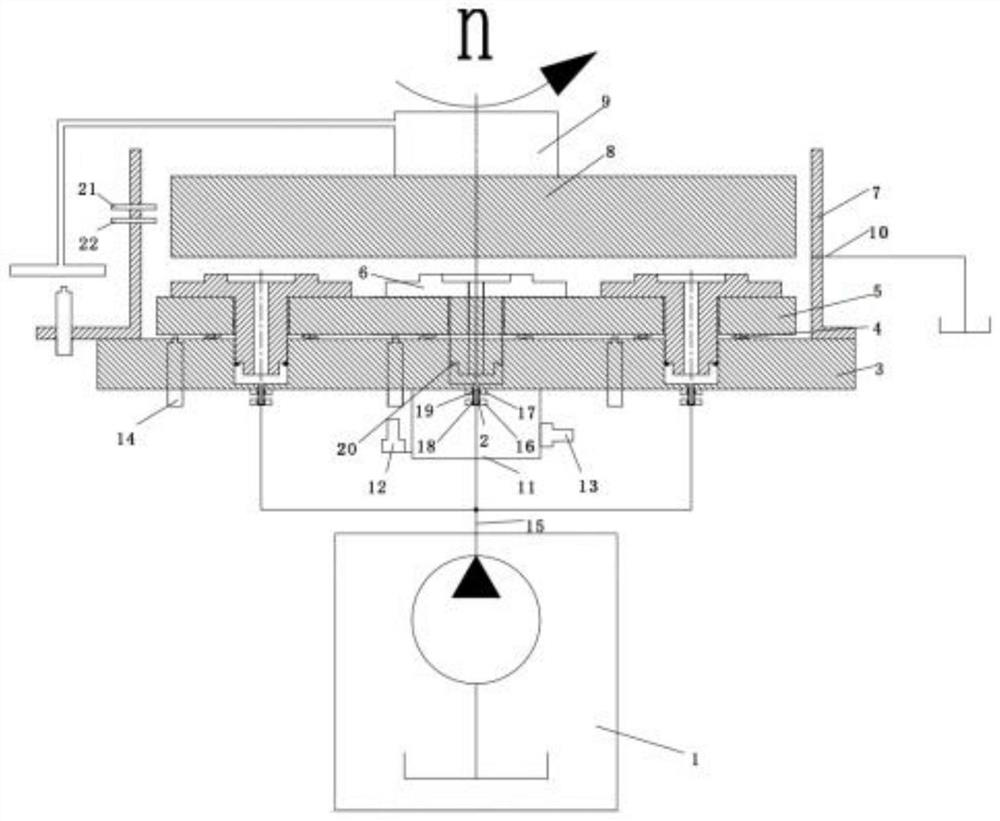

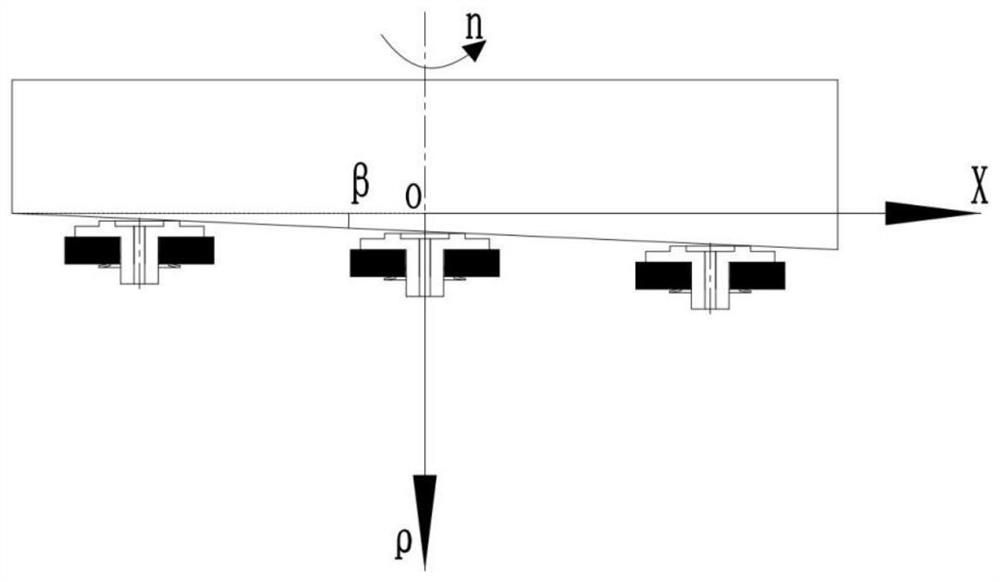

Method and test device for simulating piston shoe pair friction under high-speed and high-pressure working conditions of plunger pump

PendingCN114199707AMeet the basic requirements of the friction stateImprove testabilityUsing mechanical meansInvestigating abrasion/wear resistanceWear testingEngineering

The invention provides a method and a test device for simulating piston shoe pair friction of a plunger pump under high-speed and high-pressure working conditions, and the test device comprises an oil supply pump station, a fixed damper, a lower clamp, a disc spring, a floating disc, a lower test piece, an upper test piece, an oil box assembly, a vibration sensor, a torque sensor, an eddy current displacement sensor, and a friction wear testing machine. The test method can directly test lubrication and friction characteristic information of the sliding shoe pair, and has excellent testability, and the test result is accurate and stable. The test bed utilizes a constant pressure oil source type static pressure bearing theory to construct a static pressure lubricating environment of the sliding shoe pair, and utilizes the curved surface design of the disc spring and the surface of the upper test piece to directly simulate the friction state of the sliding shoe pair under the alternating residual pressing force.

Owner:YANSHAN UNIV

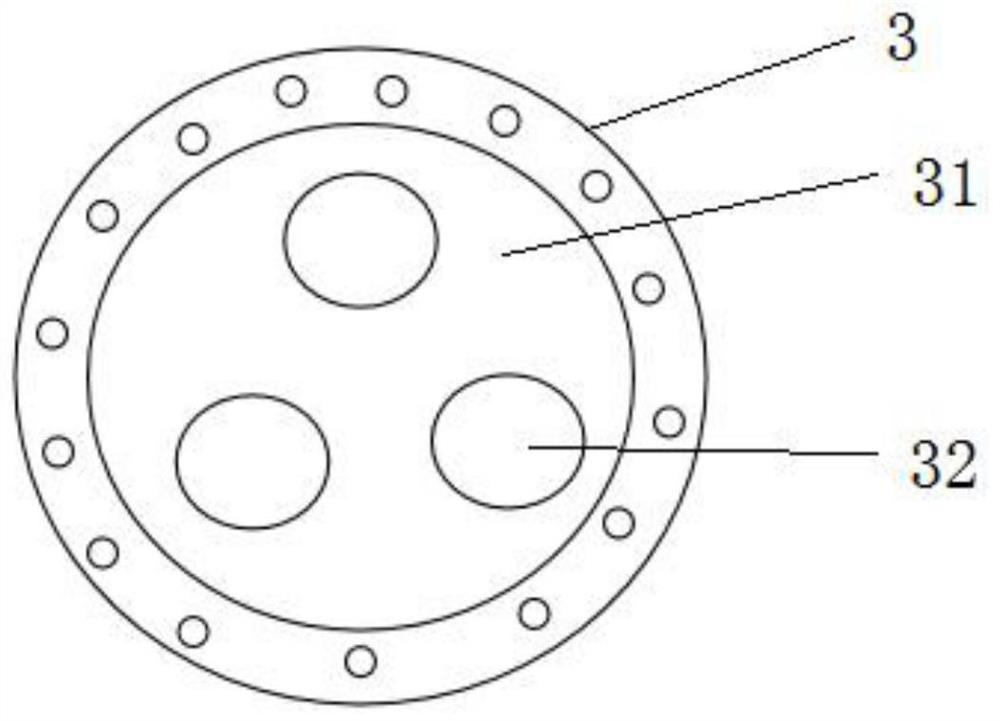

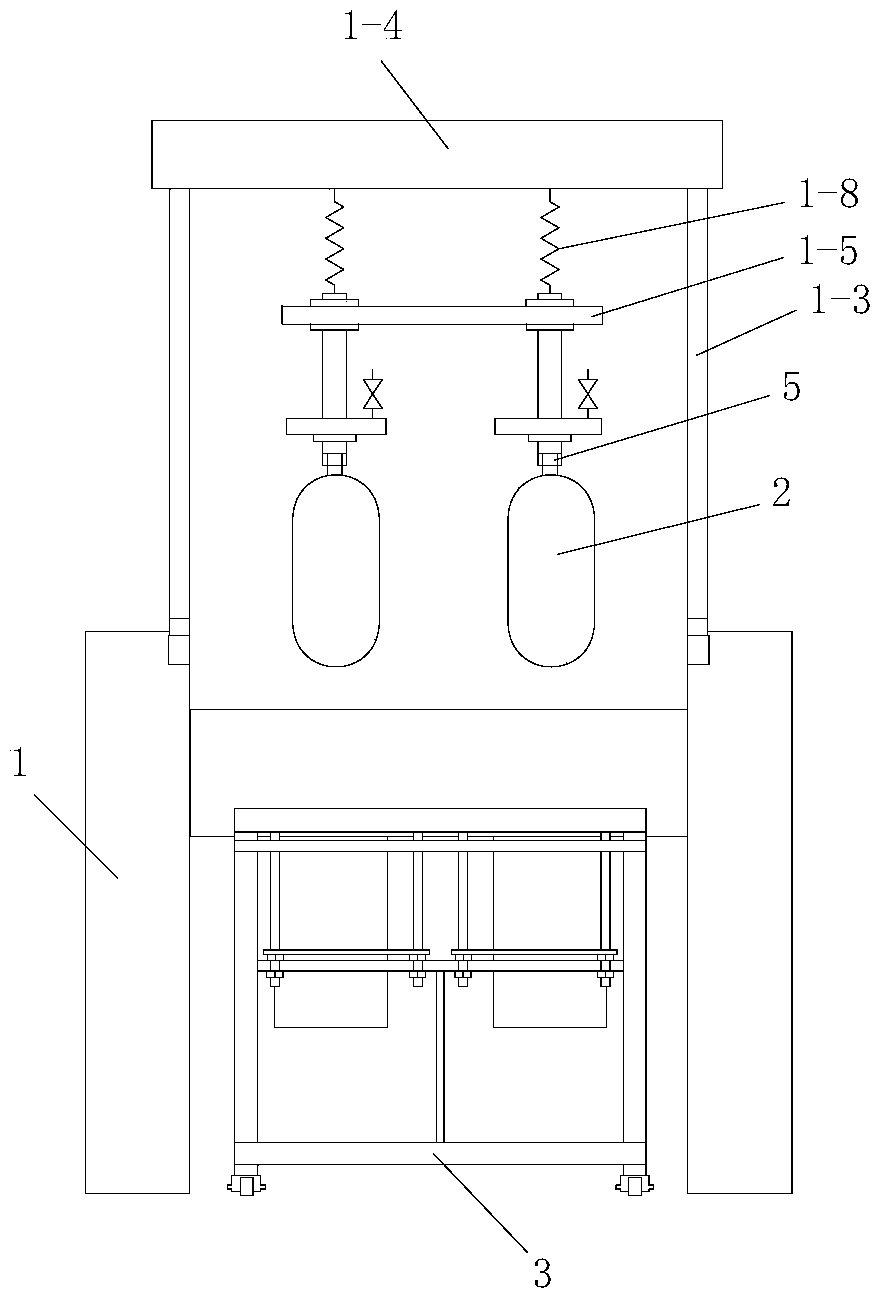

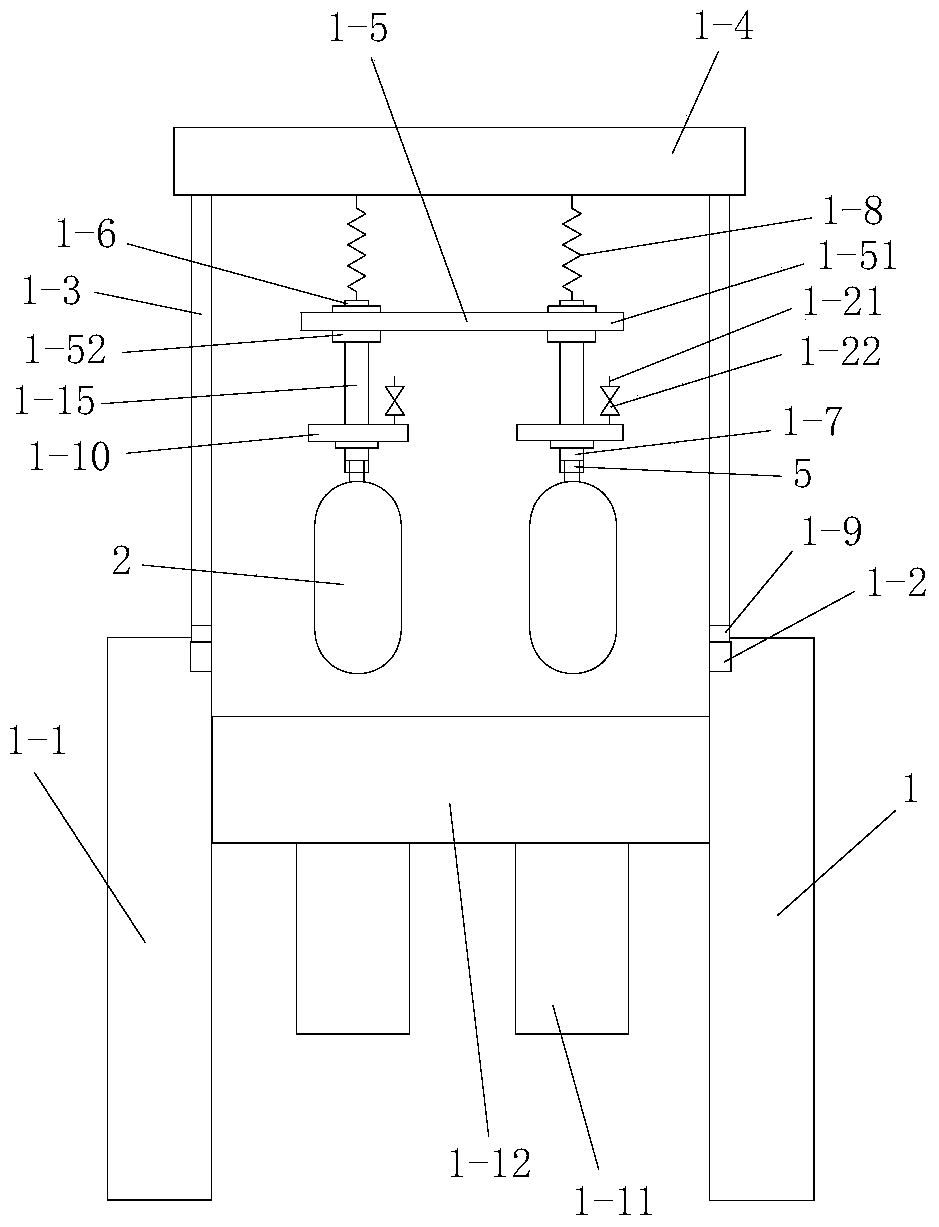

Carbon fiber cylinder detection system and method

InactiveCN105571949ASimple structureCompact structureDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesFiberCarbon fibers

The invention discloses a carbon fiber cylinder detection system and method. The detection system comprises a hydraulic pressure tester, a hydraulic pressure assisted tester and a tightness tester; the hydraulic pressure tester comprises a test rack, a test operating table, a pressurizing device, a test case mounted on the test rack and a test cart for multiple cylinders to be tested to be placed steadily on; the hydraulic pressure assisted tester comprises a cylinder clamp, a conveying cart and a cylinder emptying and drying apparatus; the tightness tester comprises a tightness test unit and a second gas supply device supplying gas to multiple cylinders to be tested, and the tightness test unit is a cabinet type tightness test unit or a trough type tightness test unit; the method comprises the steps: first, hydraulic pressure testing; second, emptying and drying treatment; third, tightness testing. This system is reasonable in design and simple to operate and effective to use and enables the hydraulic pressure test and tightness test process of multiple carbon fiber cylinders to be finished simply and quickly.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

Tensioning device suitable for underground construction defective anchor rod

PendingCN108756966AFreely adjust the offset angleImprove applicabilityAnchoring boltsRound tableArchitectural engineering

The invention discloses a tensioning device suitable for an underground construction defective anchor rod. The tensioning device comprises a hollow oil cylinder, an oil cylinder fixing arm, an angle adjusting device, a round table support, a drawing connecting rod and a hydraulic power source. The drawing angle of the drawing connecting rod can be changed through the angle adjusting device so thatthe drawing connecting rod and the construction defective anchor rod can be in a coaxial position, then the drawing connecting rod is connected to the defective anchor rod through a connecting sleeve, and after the position of the angle adjusting device is fixed, radial tension detection is performed on the construction defective anchor rod through the extension of the hollow oil cylinder; and after the detection is completed, the defective anchor rod can be fastened by using a tray and bolts under the condition that the defective anchor rod is under high pre-tightening force. The tensioningdevice can perform a tensile test on the construction defective anchor rod coaxially, thereby effectively detecting the anchoring force of the construction defective anchor rod and applying high pre-tightening force to the construction defective anchor rod.

Owner:HUNAN UNIV OF SCI & TECH

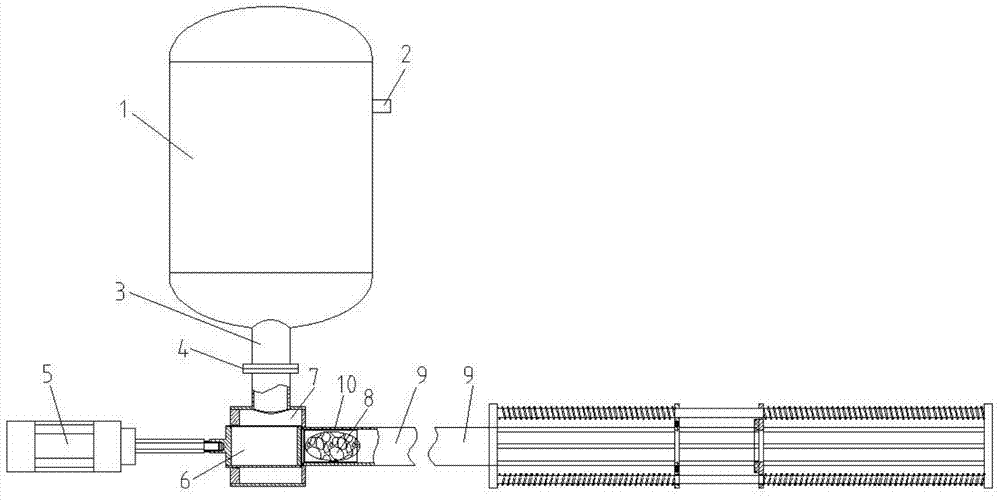

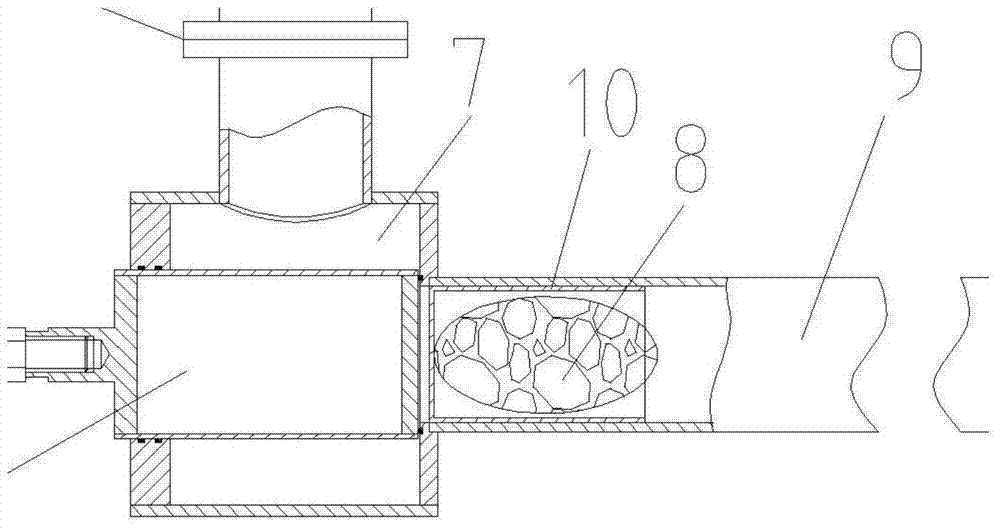

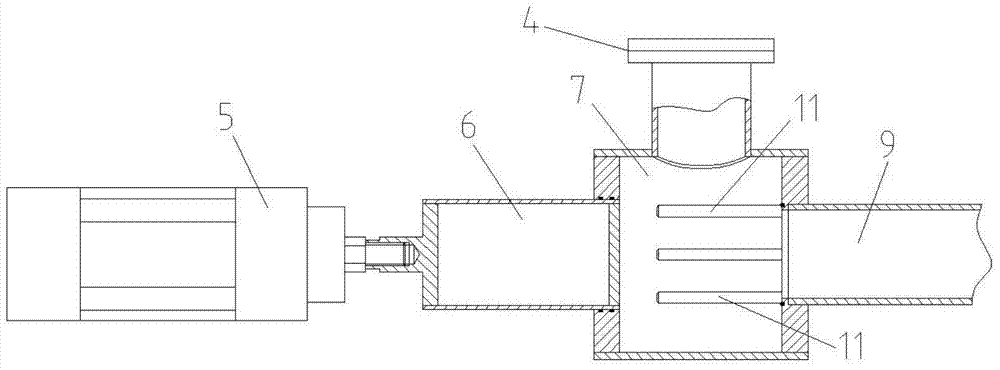

Turbofan engine inlet part birdshot impacting device

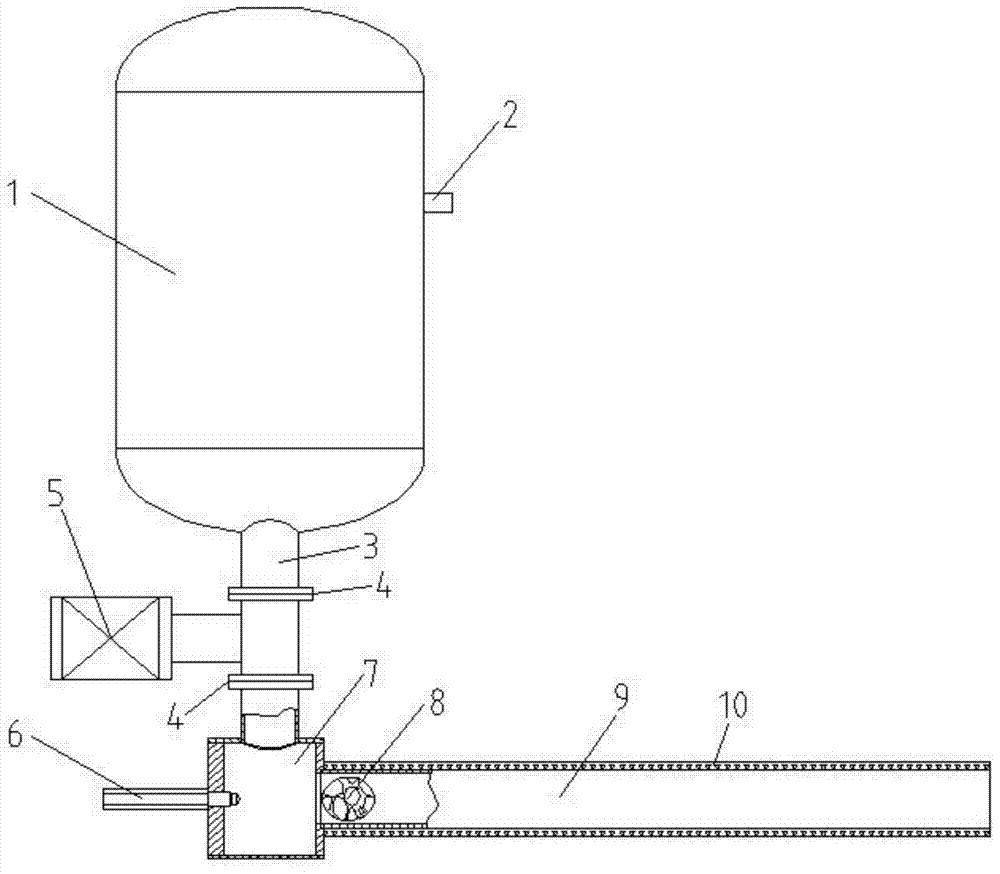

InactiveCN103939218AEasy to processIncrease flight speedTurbine/propulsion air intakesSpool valveAviation

The invention discloses a turbofan engine inlet part birdshot impacting device, and belongs to the technical field of aviation equipment. The turbofan engine inlet part birdshot impacting device comprises an air storage tank, a locking air cylinder, a cabin sliding valve, a birdshot filling launching bin, a birdshot launching pipe, a birdshot supporting rod, a birdshot inlet, a sliding valve groove, a birdshot inlet sliding valve and a birdshot shell stripper, wherein the inlet of the birdshot launching pipe is connected with the birdshot filling launching bin; the cabin sliding valve and the birdshot supporting rod are arranged in the birdshot filling launching bin, and the locking air cylinder is arranged outside the birdshot filling launching bin and is connected with the cabin sliding valve together; the birdshot inlet and the sliding valve groove are both arranged on the same side wall of the birdshot filling launching bin, and the birdshot shell stripper and the outlet of the birdshot launching pipe are connected together. The turbofan engine inlet part birdshot impacting device provided by the invention has the advantages that impact force is generated for a birdshot by controlling the high pressure gas, the birdshot rapidly flies to a target, and a birdshot impacting effect is realized; and a test device is simple, a part is easy to purchase or process. The whole device is easy to implement, and the cost is low.

Owner:SHANGHAI JIAO TONG UNIV

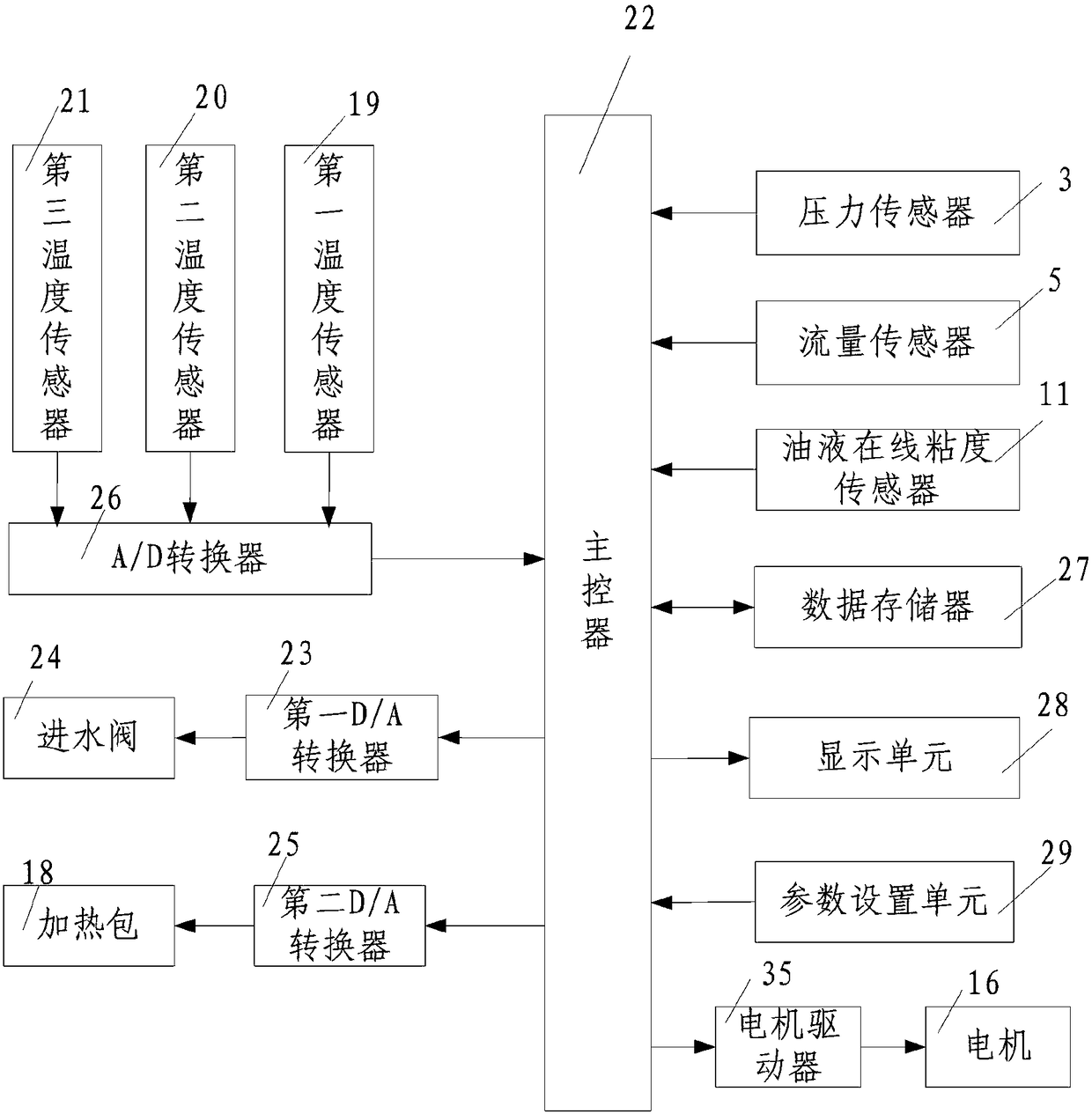

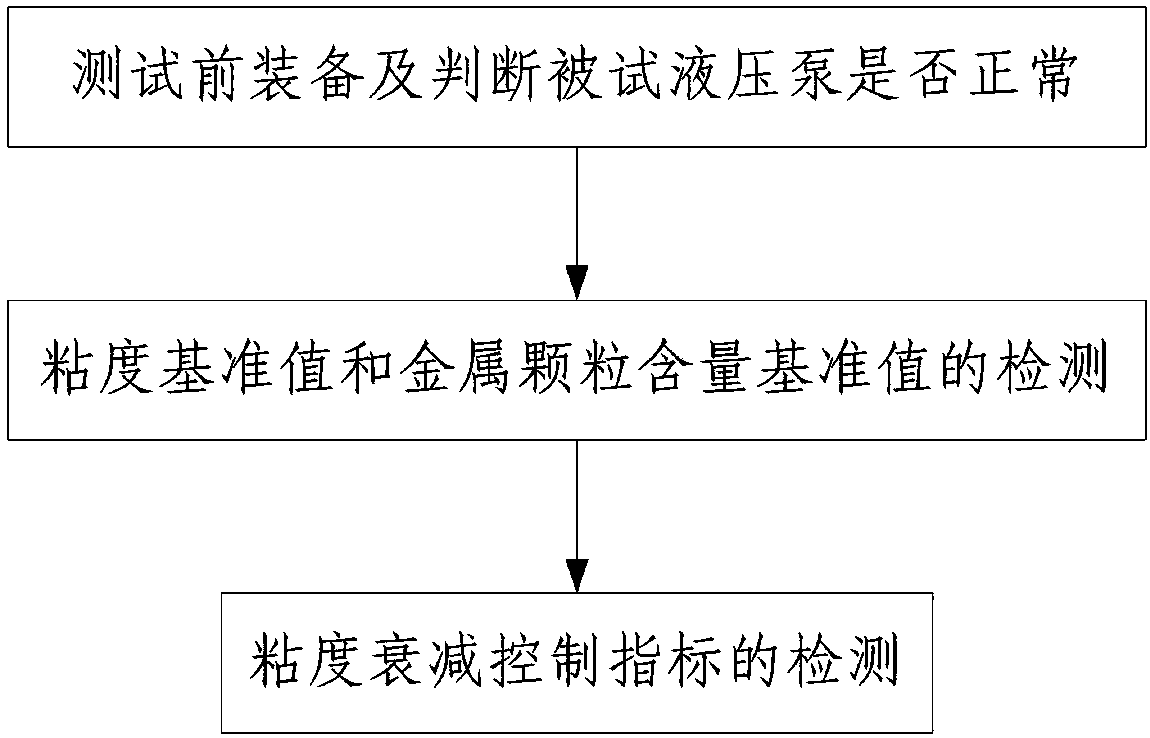

Aviation hydraulic oil viscosity attenuation control index test system and test method

PendingCN108195720ASimple structureReasonable designFlow propertiesAuxillary controllers with auxillary heating devicesAviationIndex test

The invention discloses an aviation hydraulic oil viscosity attenuation control index test system and a test method. The test system comprises a monitoring device and a test platform for the mountingof a tested hydraulic pump, and the test platform comprises an oil tank used for supplying oil to the tested hydraulic pump, a heating and cooling module used for controlling the temperature of the return oil of the tested hydraulic pump, a filter used for filtering the return oil of the tested hydraulic pump and connected to the oil tank, and an on-line oil viscosity sensor used for detecting theviscosity of the return oil of the tested hydraulic pump. The test method comprises the following steps: (1) before testing, the tested hydraulic pump is mounted, and whether the tested hydraulic pump is normal or not is judged; (2) a viscosity reference value and a metallic element content reference value are detected; (3) a viscosity attenuation control index is detected. The aviation hydraulicoil viscosity attenuation control index test system has the advantages of simple structure, reasonable design, easiness in use and operation and good use effect, and can easily and quickly carry outthe testing of an aviation hydraulic oil viscosity attenuation control index, and moreover, the testing precision is higher.

Owner:陕西东方长安航空科技有限公司

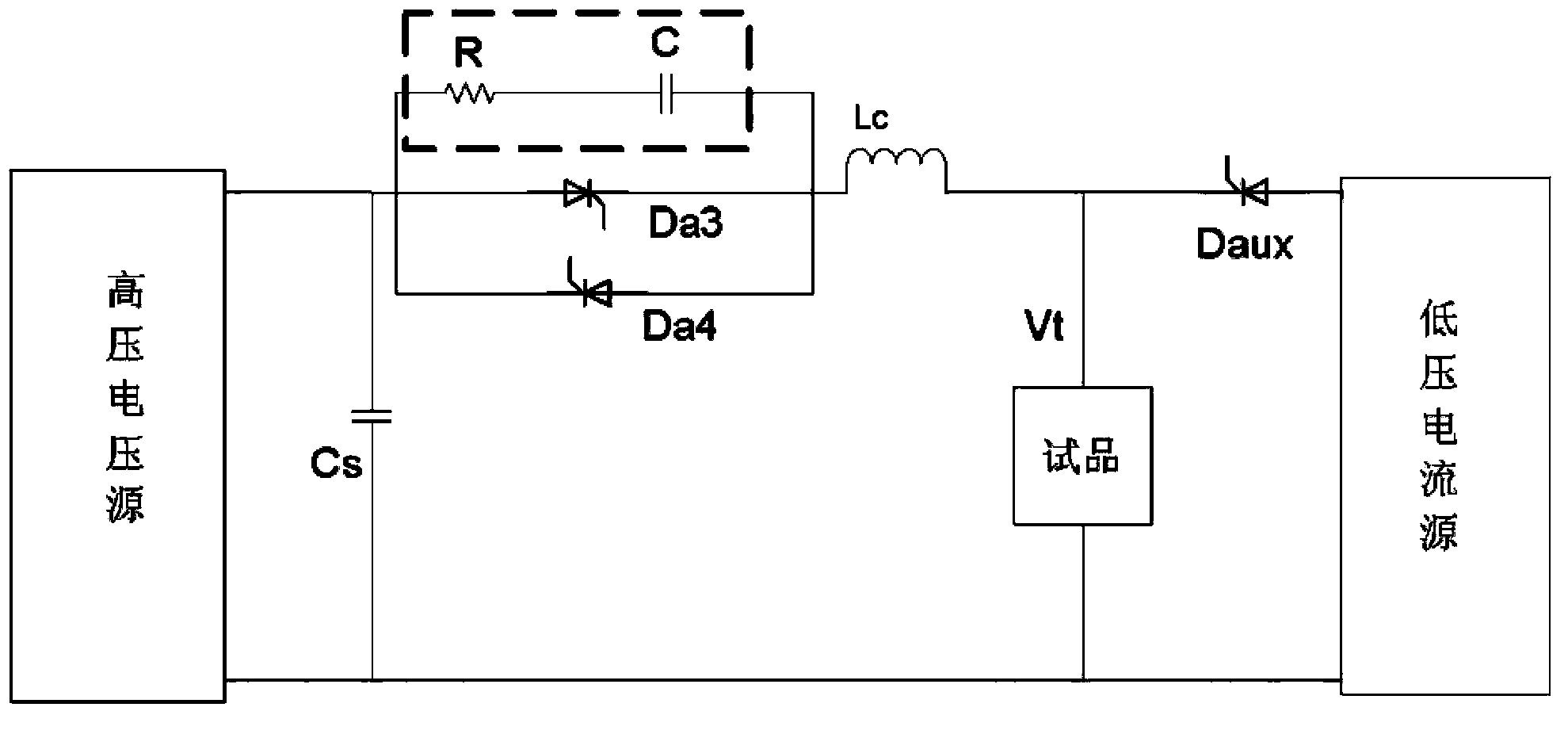

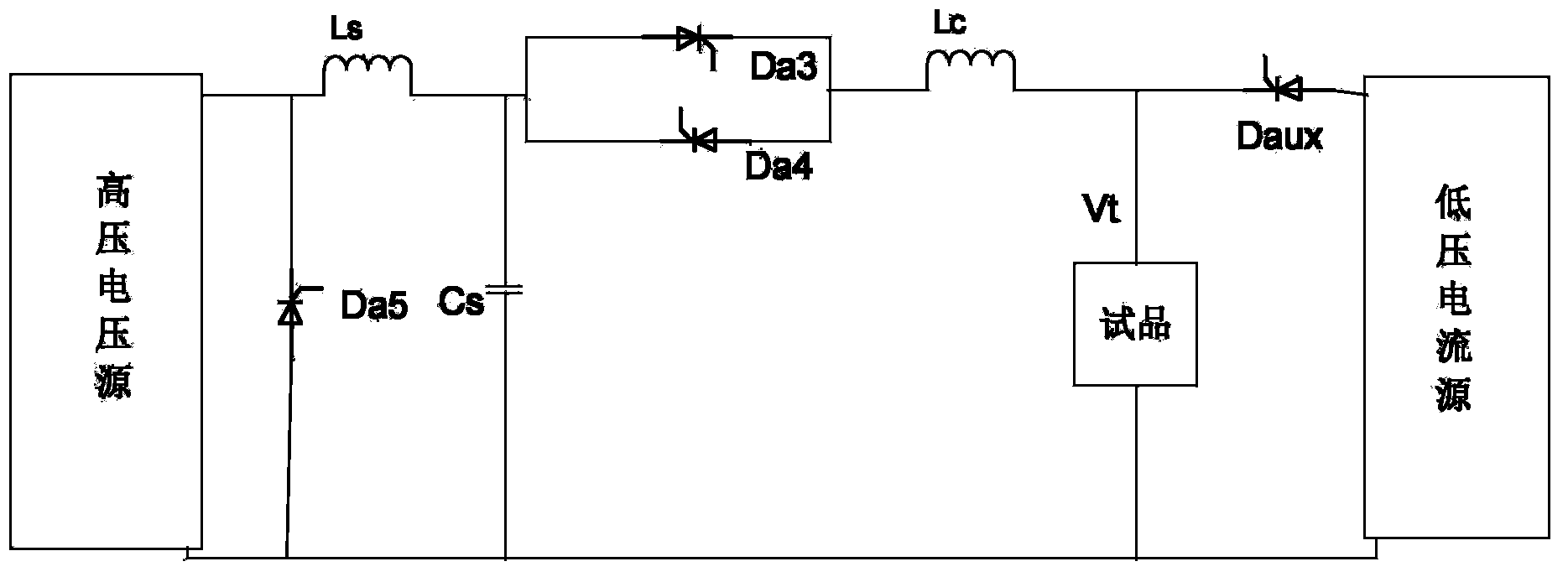

High-voltage direct-current power transmission commutation transient low-voltage test method and circuit thereof

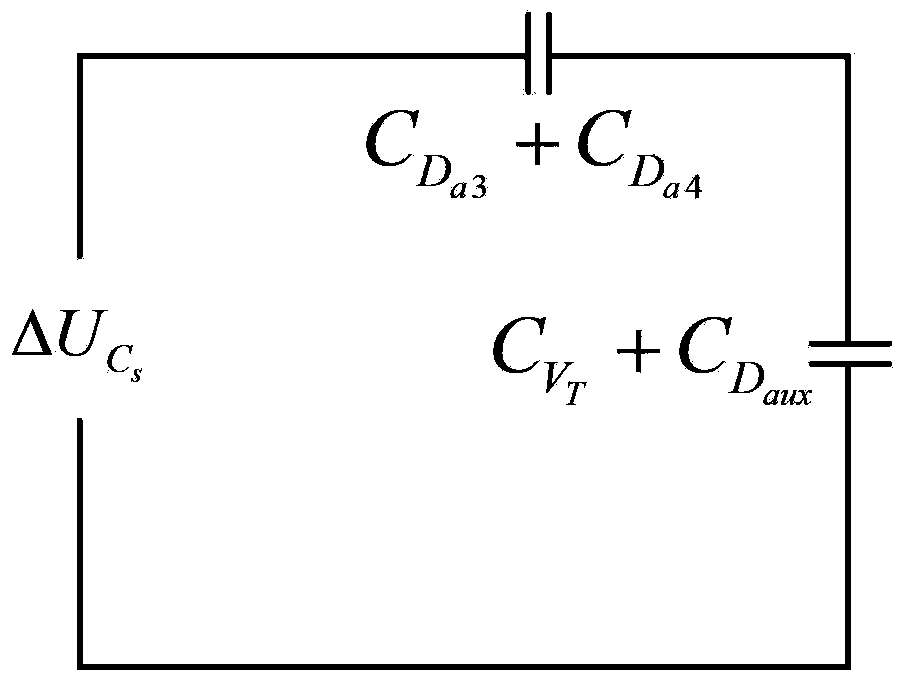

ActiveCN103353562ATrue Response Voltage Stress CharacteristicsThe test process is stable and reliableElectrical testingLow voltageHigh-voltage direct current

The present invention relates to a high-voltage direct-current power transmission commutation transient low-voltage test method and a circuit thereof. The circuit comprises a high-voltage voltage source, a low-voltage current source and auxiliary control valves Da5, Da4 and Da3. In the test method, according to the triggering timing of the auxiliary control valves Da5, Da4 and Da3, a high backward recovery voltage and a low forward triggering voltage can be applied over a test valve Vt when a forward voltage is established on the test valve Vt, such that voltage stress characteristics in a direct-current power transmission commutation transient operation process can be truly reflected, and the test requirements can be satisfied by controlling the triggering of the auxiliary control valves by a control system, requiring no additional auxiliary equipment in the test circuit and eliminating the need to consider the heat radiation of resistors. The method and circuit provided by the invention are simple to implement, and can increase the test efficiency.

Owner:XJ ELECTRIC

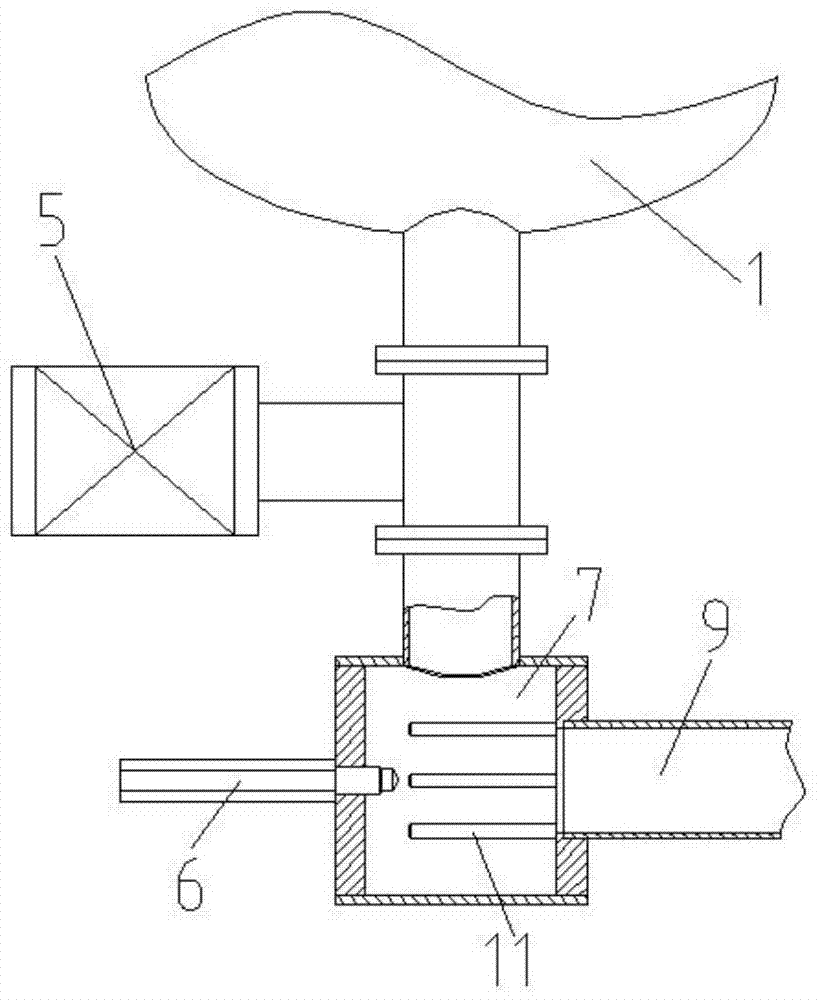

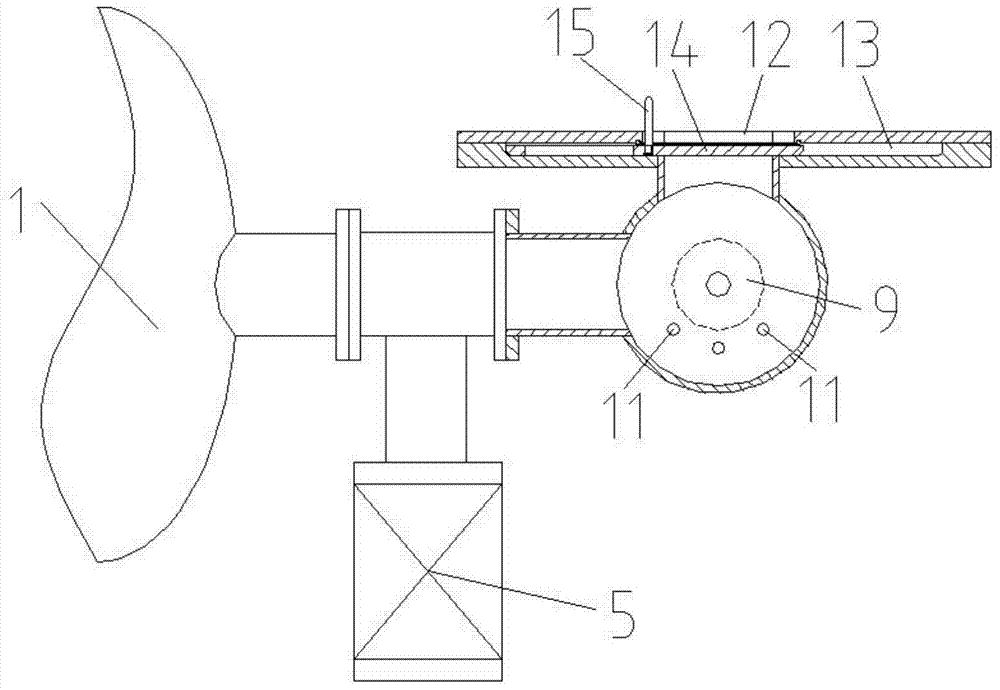

Electronic control type aimable ice shot impact testing device

The invention discloses an electronic control type aimable ice shot impact testing device and belongs to the technical field of aeronautical facilities. The electronic control type aimable ice shot impact testing device comprises an air storage tank, an electronic control valve, a sighting device, an ice shot filling and launching compartment, an ice shot launching tube, an ice shot supporting rod, an ice shot inlet, a sliding valve groove, an ice shot inlet sliding valve and a hand lever, wherein the inlet of the ice shot launching tube is connected with the ice shot filling and launching compartment, the ice shot supporting rod is arranged in the ice shot filling and launching compartment, the sighting device is arranged on the ice shot filling and launching compartment, the ice shot inlet and the sliding valve groove are formed in the same lateral wall of the ice shot filling and launching compartment, the ice shot inlet sliding valve is arranged in the sliding valve groove, and the hand lever is fixedly connected with the ice shot inlet sliding valve. By means of the electronic control type aimable ice shot impact testing device, impact force is applied on ice shots by controlling high-pressure air, and therefore, the ice shots fly to a target quickly to achieve ice shot impact effect. The electronic control type aimable ice shot impact testing device is simple, parts are purchased or manufactured easily, the whole electronic control type aimable ice shot impact testing device can be implemented easily, and cost is low.

Owner:SHANGHAI JIAO TONG UNIV

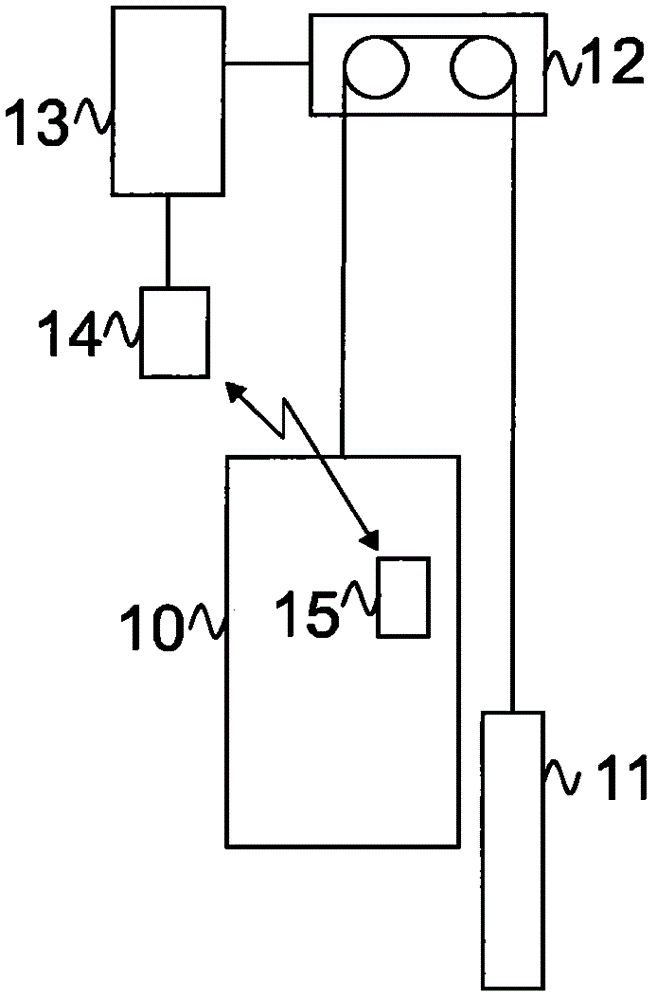

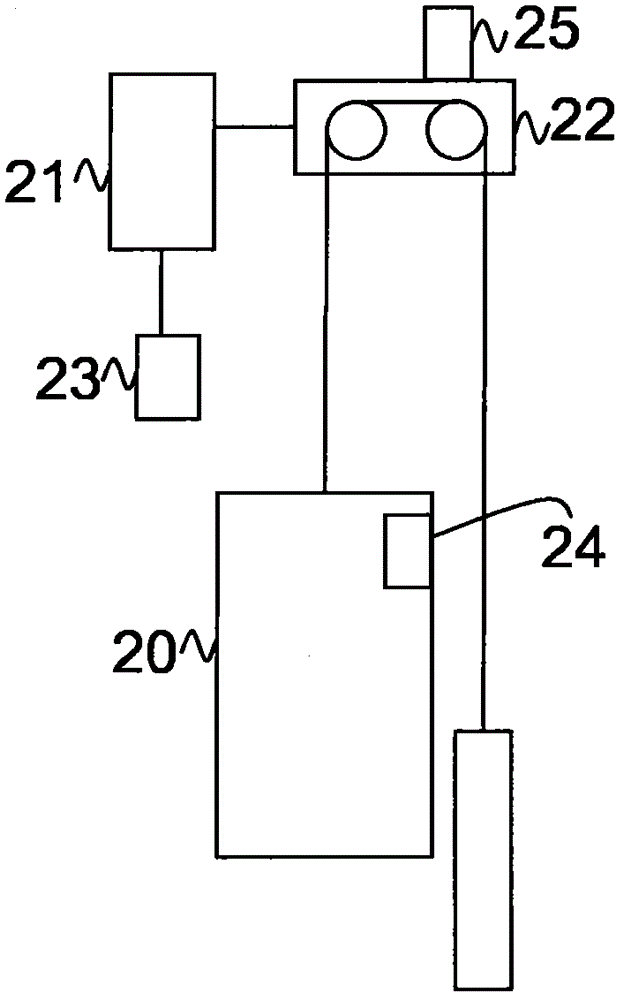

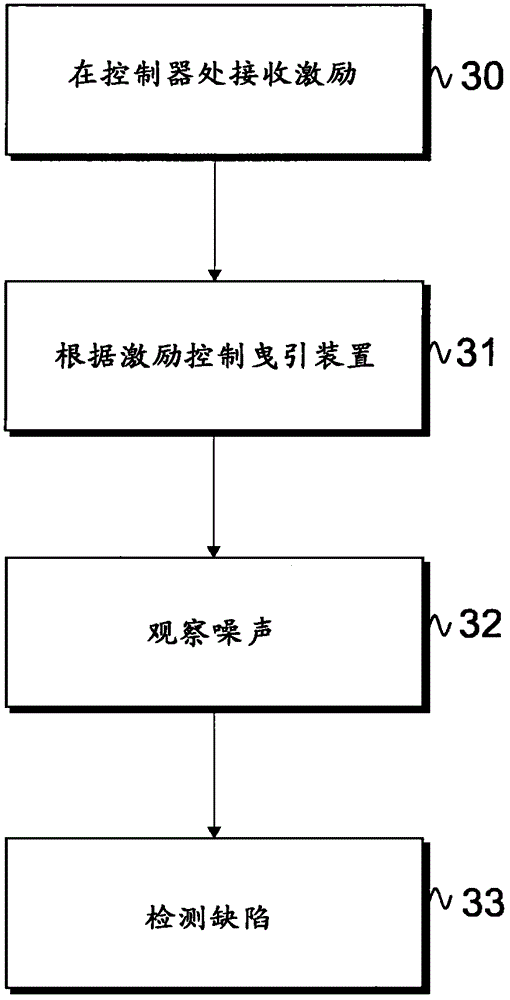

Elevator structure test

ActiveCN105164039AThe test process is stable and reliableRepeatable testing processVibration measurement in fluidElevatorsEngineeringMovement control

Various embodiments in the invention relate to an elevator structure test. Loose joints and other defects, such as manufacturing, installation, wearing and other similar defects, are hard to find. Especially in case of passenger elevator it is crucial to find these defects in order to produce safe elevators. Testing can be done using a special test signal that is formed by combining an excitement signal with movement control signal. The test signal causes purposively pulsating or oscillating movement of the elevator car that deviates from the ordinary movement of the elevator. This movement causes noises from loose joints and other defects. The sources of these noises can then be located and the defects can be fixed.

Owner:KONE CORP

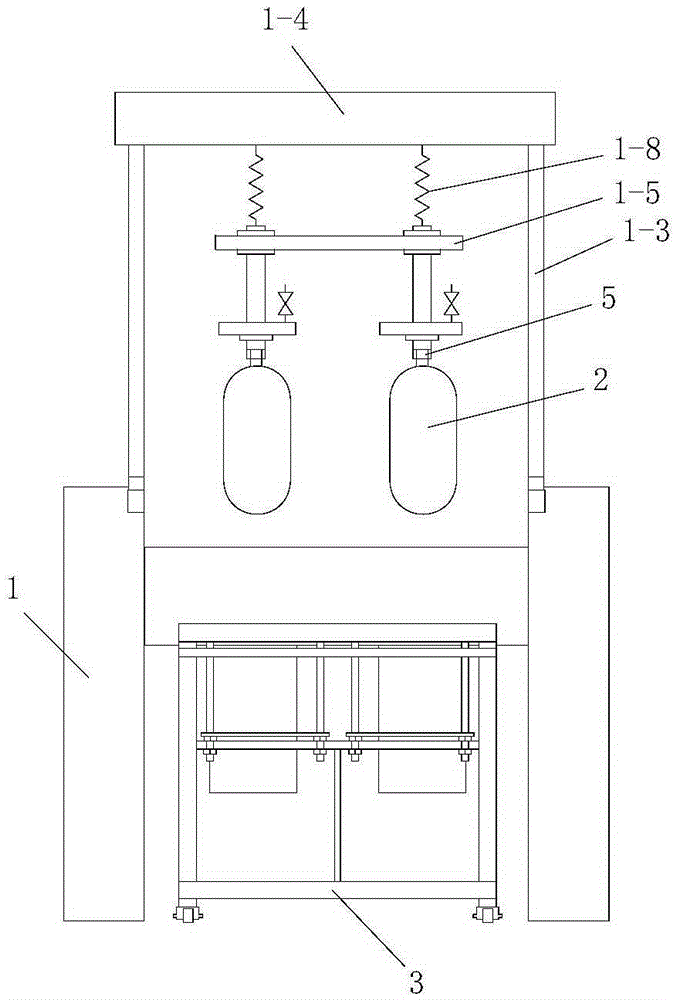

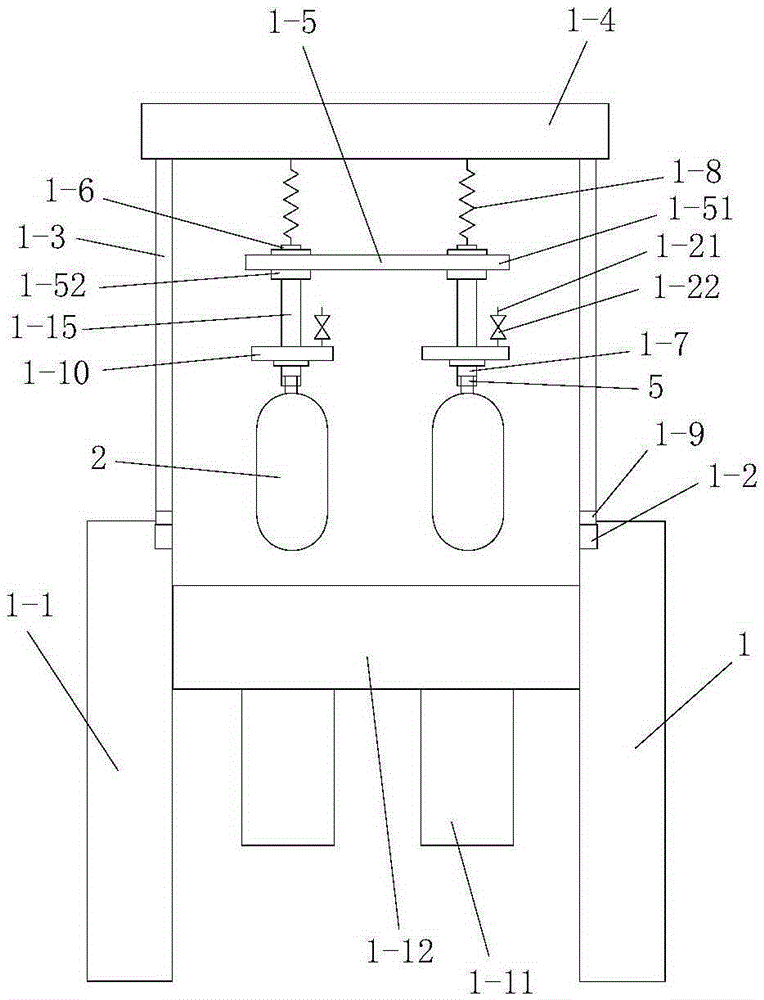

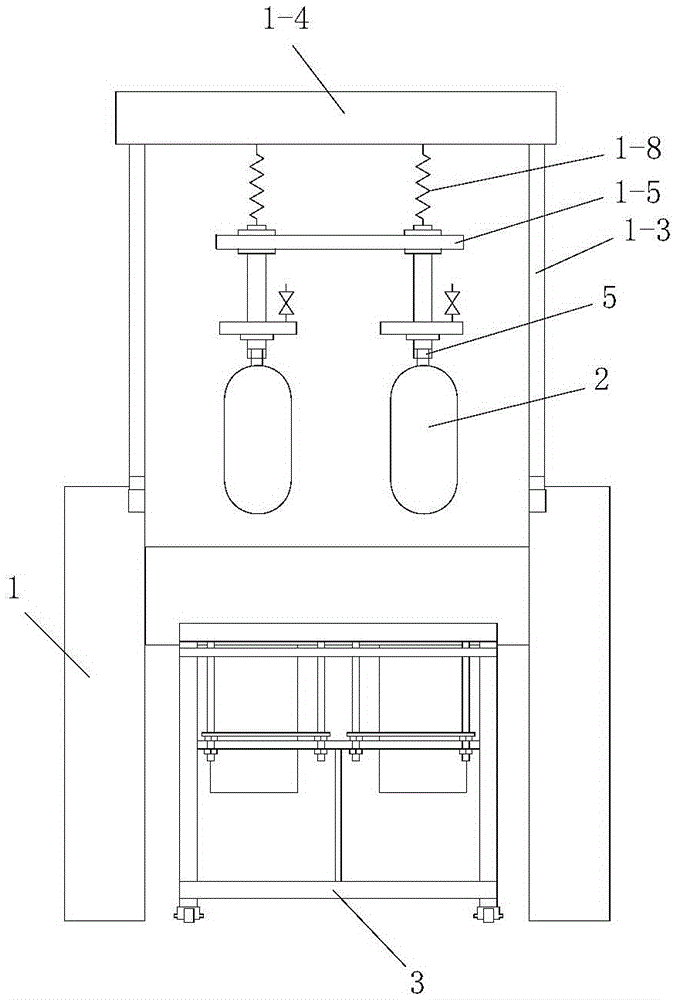

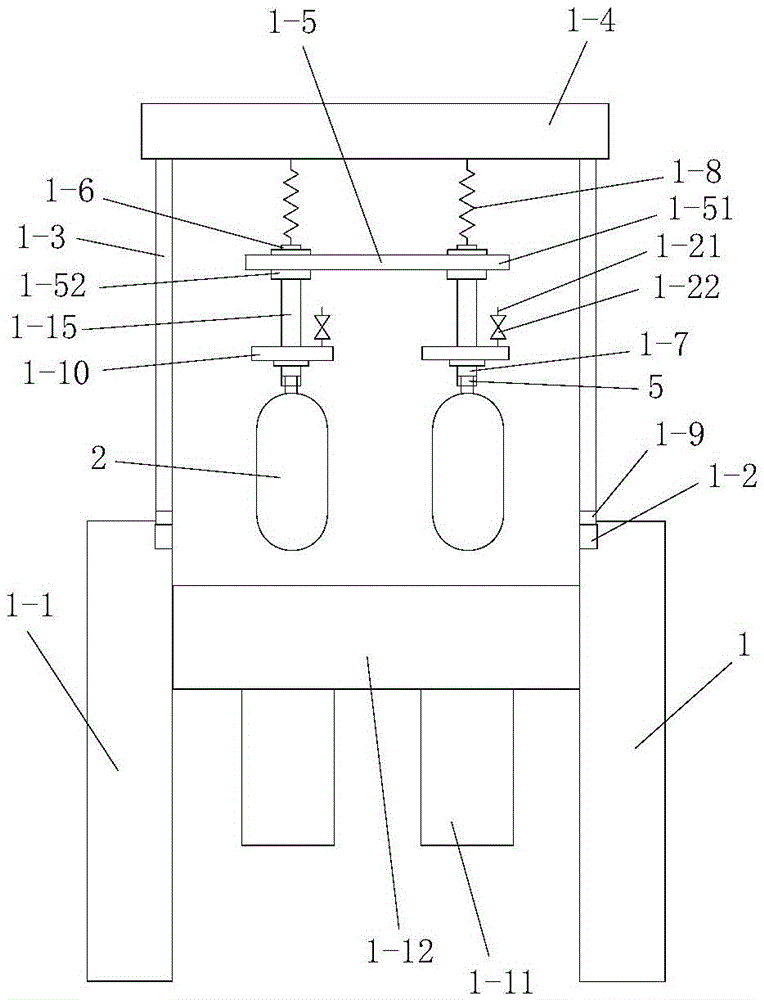

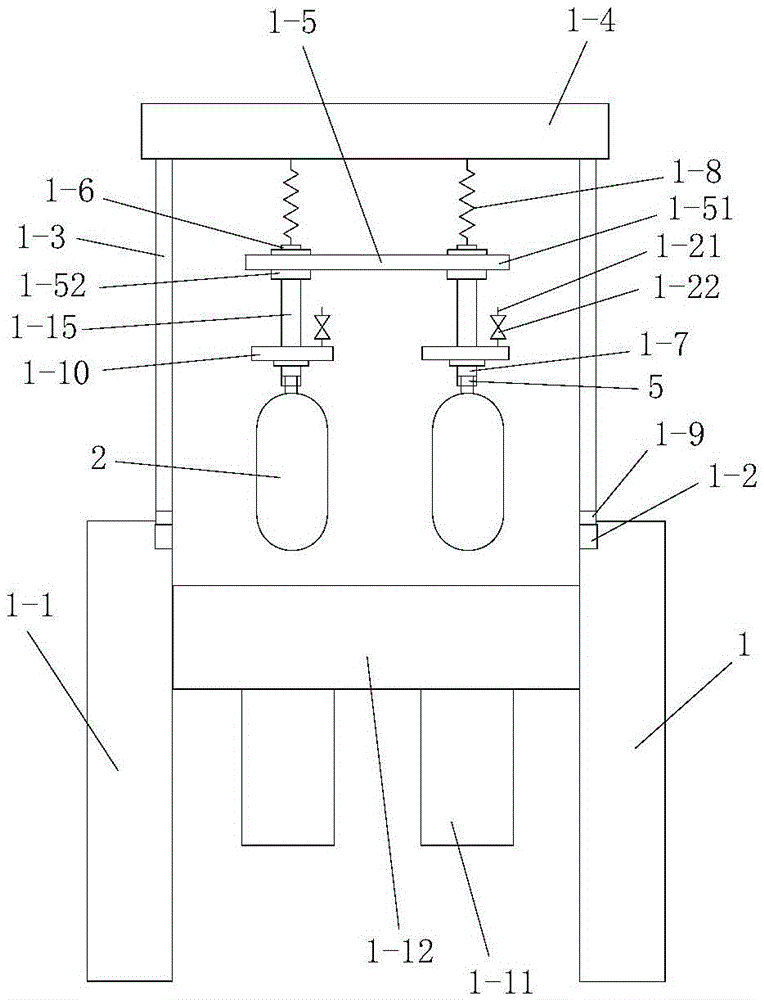

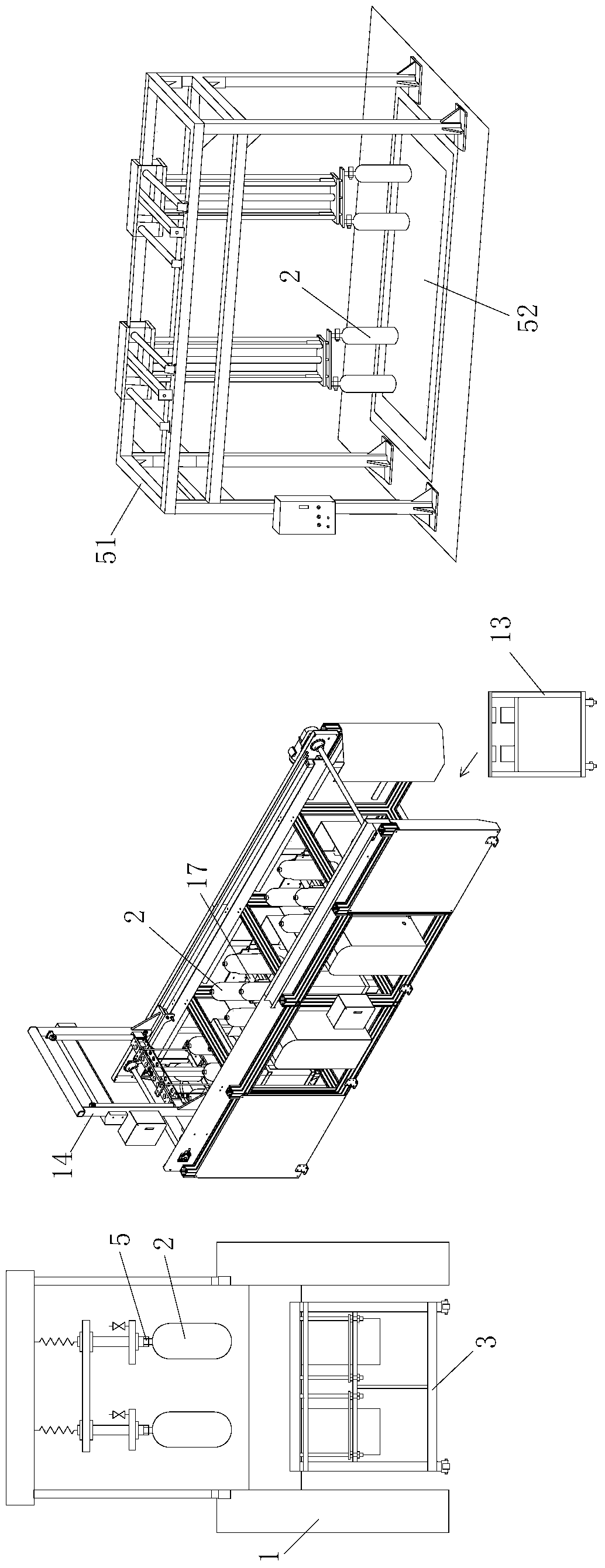

Carbon fiber gas cylinder hydraulic pressure test device and hydraulic pressure test method

InactiveCN105403463ASimple structureCompact structureMaterial strength using tensile/compressive forcesFiberCarbon fibers

The present invention discloses a carbon fiber gas cylinder hydraulic pressure test device and a hydraulic pressure test method, the carbon fiber gas cylinder hydraulic pressure test device comprises a hydraulic pressure test unit for testing deformation and pressure bearing capacity of a plurality of to-be-tested gas cylinders, and a hydraulic pressure auxiliary test unit located in front side of the hydraulic pressure test unit; the hydraulic pressure test unit comprises a test rack, a test console, a pressurization unit, a test case and a test vehicle; the hydraulic pressure auxiliary test unit comprises a gas cylinder fixture, a conveying vehicle and a gas cylinder water-pouring and drying treatment unit for performing water pouring and drying treatment on the to-be-tested gas cylinders, and a horizontal placement platform for horizontal placement of the gas cylinder fixture is arranged on the upper part of the conveying vehicle; and the method comprises the following steps: 1, hydraulic pressure test; and 2, water pouring and drying treatment. The carbon fiber gas cylinder hydraulic pressure test device is reasonable in design, easy to operate and good in use effect, a simultaneous testing process of the deformation and pressure bearing capacity of the plurality of gas cylinders can be completed easily, and the water pouring and drying treatment of the plurality of gas cylinders after testing can be performed easily.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

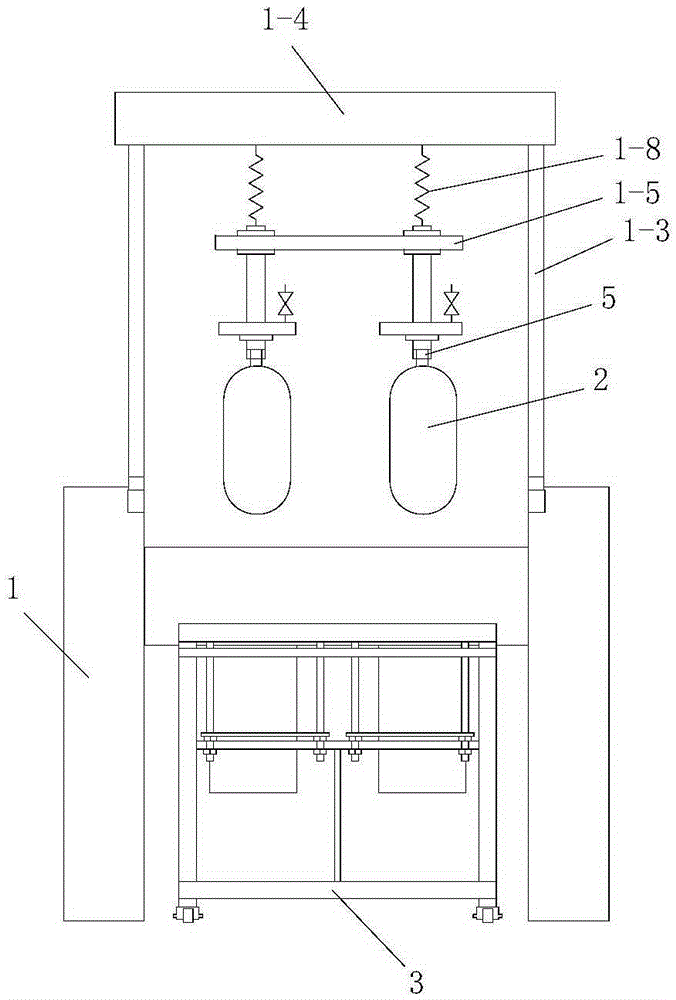

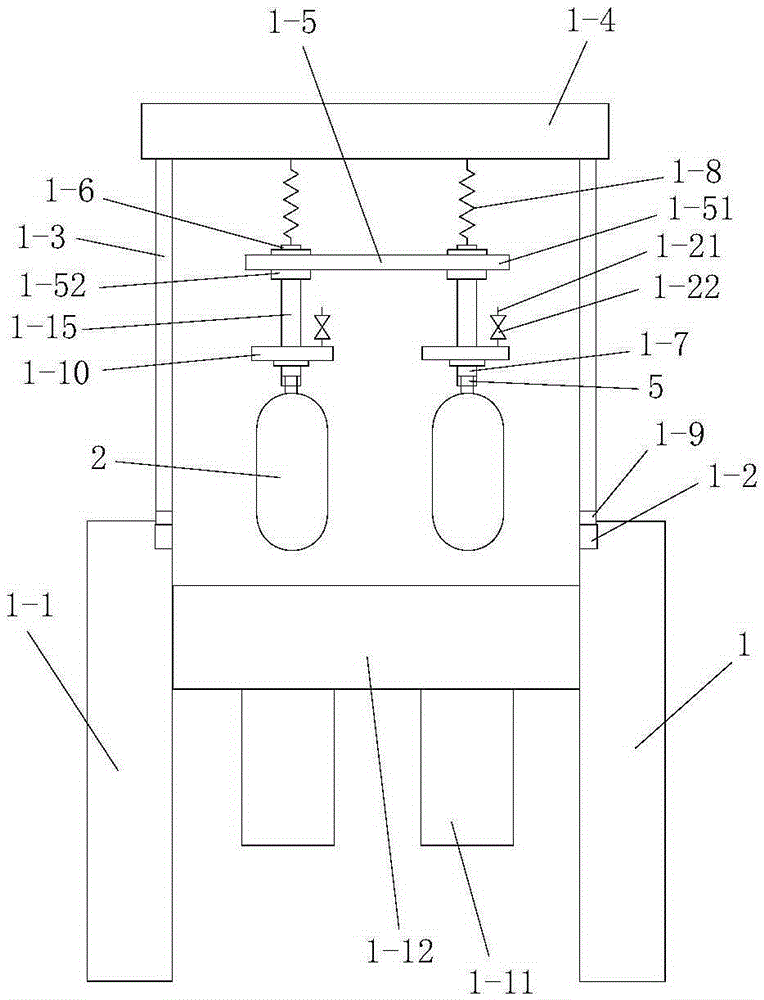

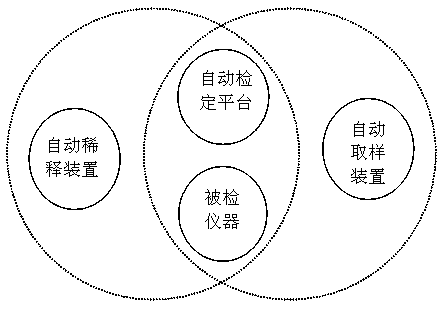

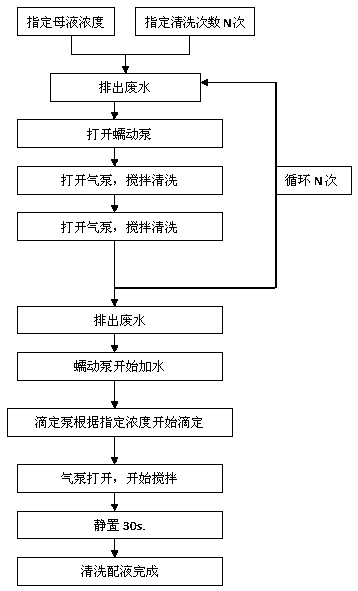

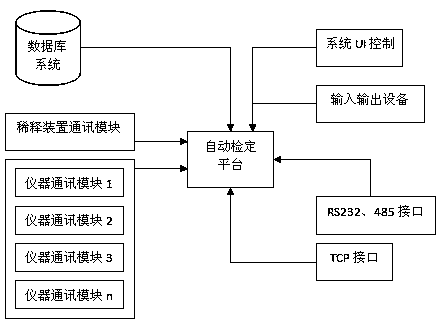

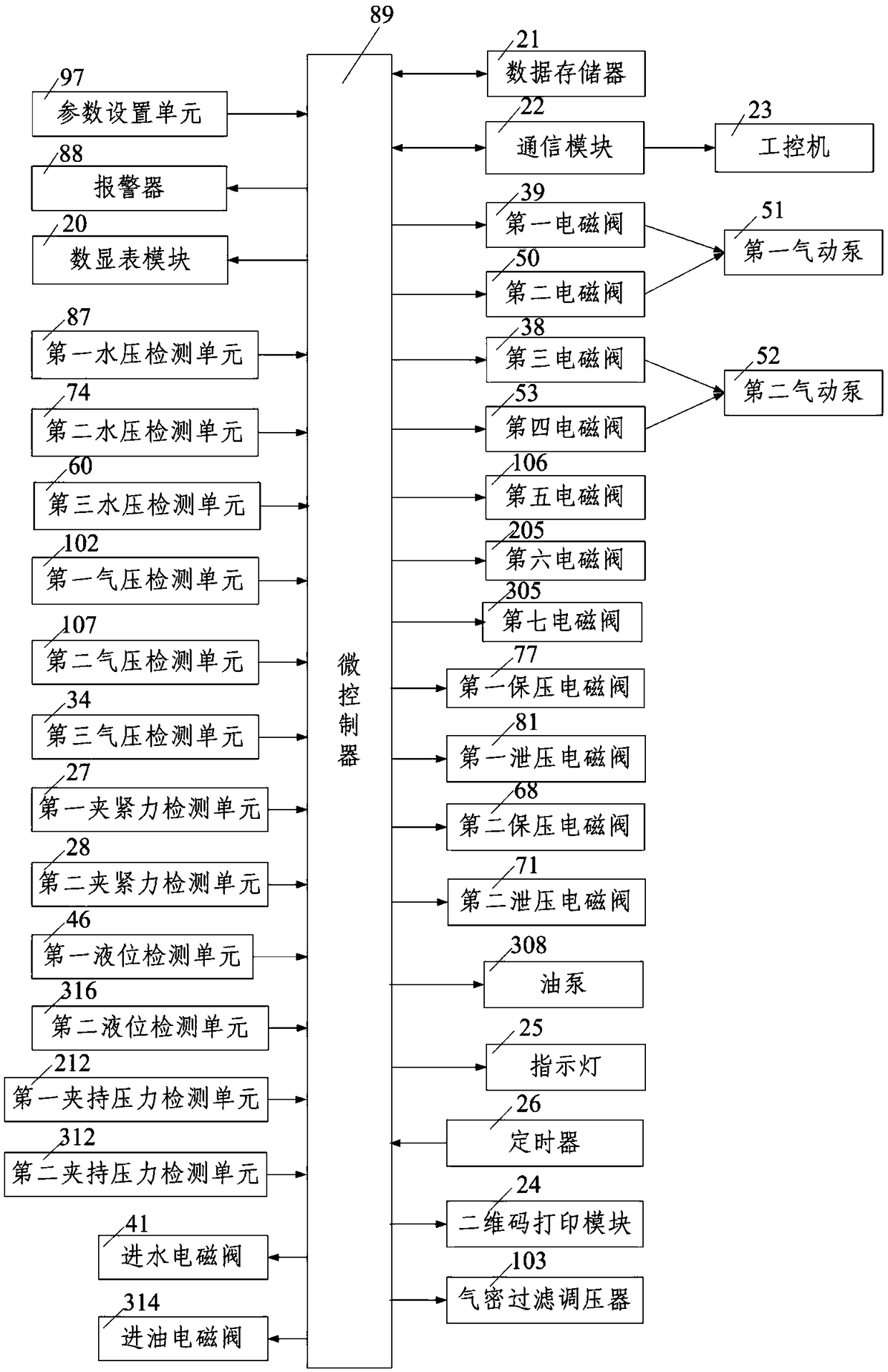

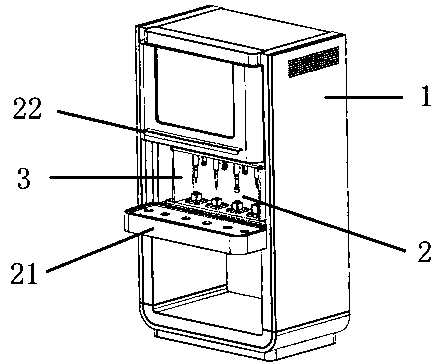

On-site automatic verification system for water quality monitor

InactiveCN108802314AThe test process is stable and reliableImprove automationTesting waterInformatizationMetrology

The invention provides an on-site automatic verification system for a water quality monitor, comprising an on-site automatic verification platform of the water quality monitor, an automatic sampling device and an automatic dilution device. The on-site automatic verification system unifies detection standards, so as to improve the automation and informationization of detection on such measuring instruments, greatly improve the efficiency of measurement and detection, and improve the detection quality; the system lowers the quality requirements on detection personnel, reduces the labor intensityof the detection personnel, reduces the consumption of reagents for detection, lowers the quality risks brought by manual solution preparation and detection on site, and better fits the general detection on such measuring instruments; the system has the advantages of wide adaptability, high intelligence, high comprehensive efficiency, etc., can better meet the requirements of existing technical specifications, and can be popularized to metrology technology institutions in various provinces and cities in China.

Owner:HUNAN INST OF METROLOGY & TEST

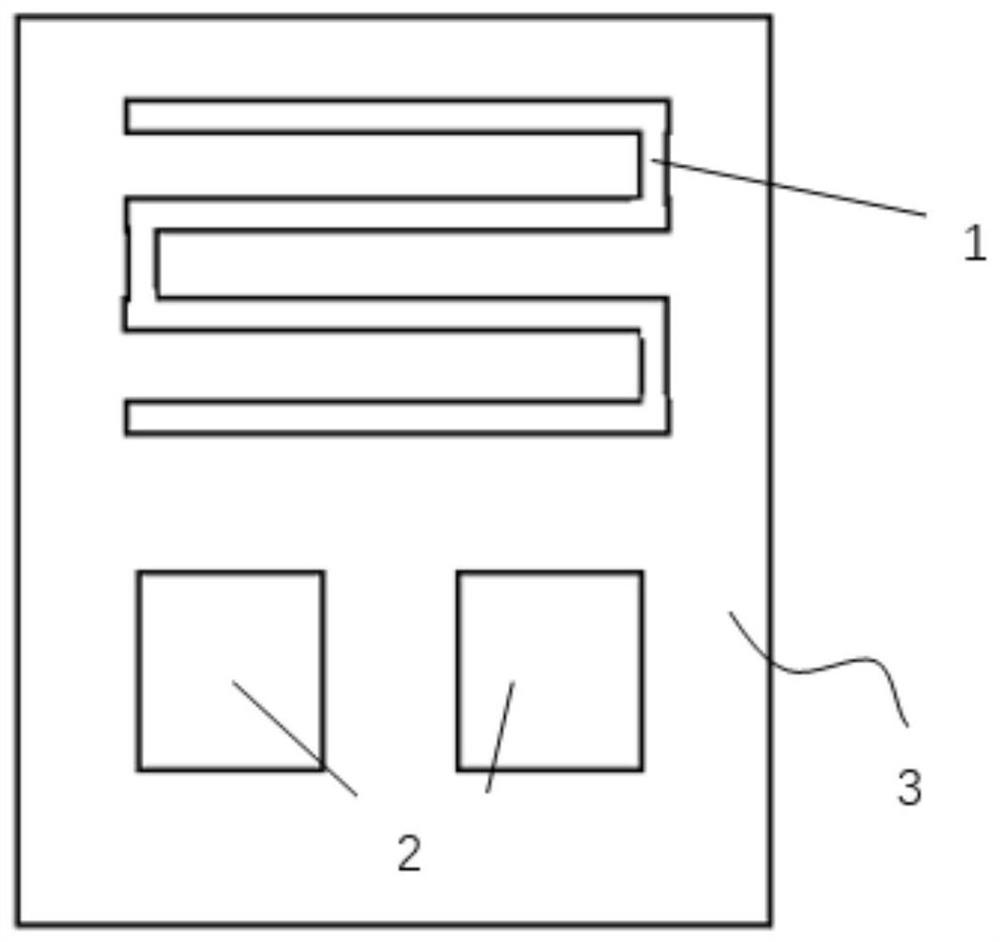

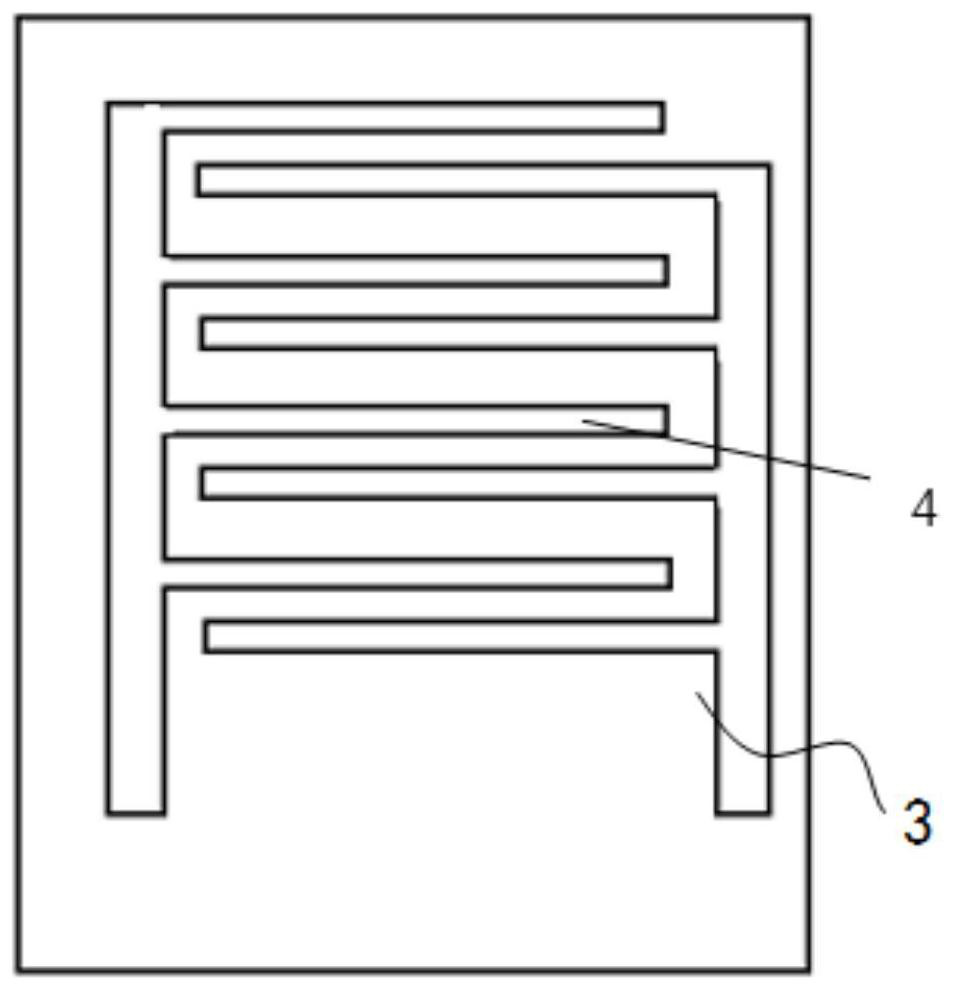

Flexible integrated sensor and method for simultaneously measuring temperature, pressure and medium

PendingCN113175948ASimple structureFew partsMeasurement devicesElectrode ContactMechanical engineering

The invention discloses a flexible integrated sensor and a method for simultaneously measuring the temperature, pressure and medium. The flexible integrated sensor comprises a circuit board and a pressure sensitive material, the circuit board is a double-sided board, one surface of the circuit board is provided with a temperature sensor and a material identification sensor, and the other surface of the circuit board is provided with an interdigital electrode; and in the using process, the temperature sensor and the material recognition sensor make contact with an object to be measured, the pressure sensitive material makes contact with the interdigital electrode, and the pressure sensitive material and the interdigital electrode form a force sensor. According to the flexible integrated sensor, measurement of various physical quantities can be completed through the same sensor, so that the types and the number of used sensors are reduced, the cost is reduced, and the flexible integrated sensor is simple in structure, small in number of components, small in device size and suitable for various measurement environments.

Owner:XI AN JIAOTONG UNIV

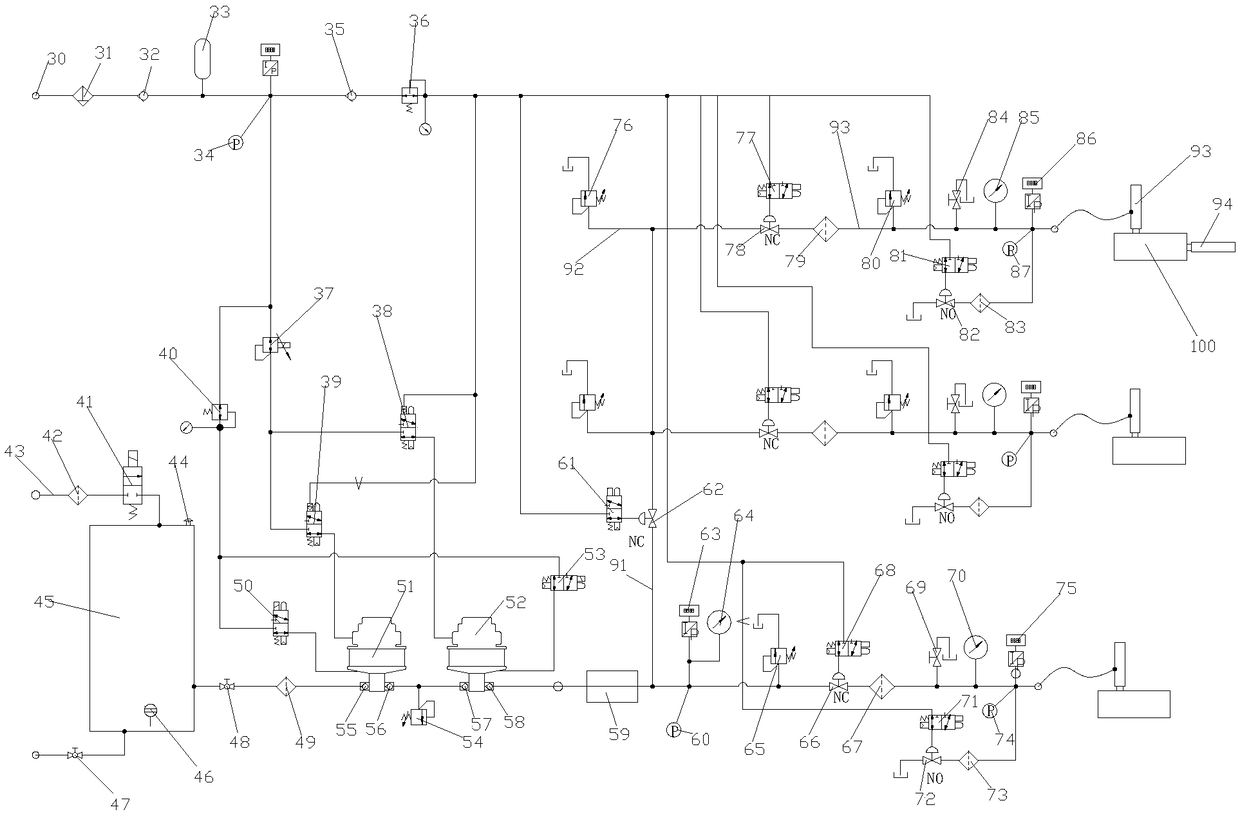

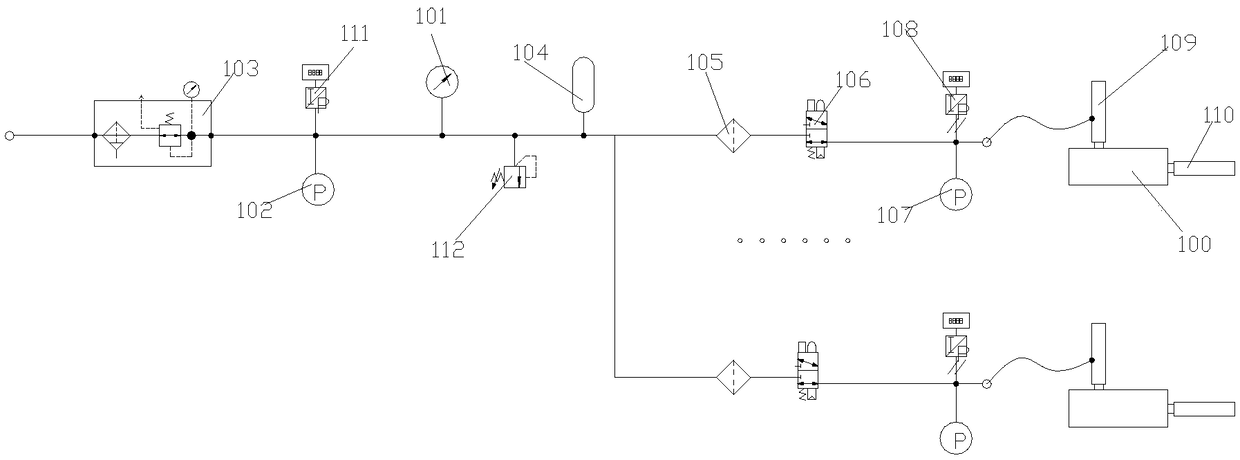

On-line irregular valve pressure testing system and testing method

PendingCN108801773ASimple structureReasonable designMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesPneumatic pressureTest fixture

The invention discloses an on-line irregular valve pressure testing system and a testing method. The testing system comprises a rack, a clamping device, a water pressure testing device, an air pressure testing device and a monitoring device, wherein the water pressure testing device comprises a water supply mechanism, a pressurizing mechanism and a pressure release mechanism. The testing method comprises the following steps: I, carrying out preparation before testing; II, defining an irregular valve, and confirming an irregular valve clamped area; III, clamping the irregular valve; IV, testingthe intensity and pressure of the valve; V, testing the sealing pressure of the valve; VI, dismounting and labeling the tested irregular valve. The system is reasonable in design simple and convenient to use and operate, good in use effect, capable of simply, conveniently and rapidly completing testing on intensity and pressure of multiple irregular valves and sealing pressure of the valves, highin security and accurate in testing.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

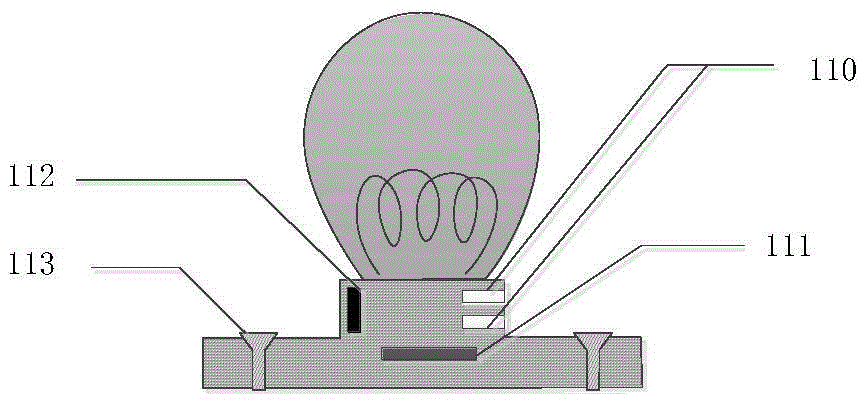

Electric energy gauge seal testing machine

ActiveCN108387439AAccurate Simulation TestAccurate dataElectrical measurementsStrength propertiesTest efficiencyEngineering

The invention relates to an electric energy gauge detection device and in particular relates to an electric energy gauge seal testing machine, aiming at solving the problems that testing equipment fortesting strength, a destructive force, a sealing force and an unsealing force of a newly developed electric energy gauge seal is lacked at present. The electric energy gauge seal testing machine is characterized by comprising an upper PC (Personal Computer) and a lower testing cabinet machine, wherein an industrial control computer is arranged at the upper part of a cabinet body; a mounting frameis arranged in a middle working region; four servo electric cylinders are arranged on the mounting frame and clamps are correspondingly mounted. The electric energy gauge seal testing machine is usedfor testing the sealing force, the unsealing force, the destructive force and the reliability of buckle type and threading type seals respectively. The electric energy gauge seal testing machine hasthe advantages that a test is accurately simulated; a whole testing process is safe and reliable and data is accurate and can be displayed through a graph; the device has the advantages of stability in operation and high testing efficiency and provides powerful guarantees for quality detection of seal products.

Owner:国网山西省电力公司计量中心

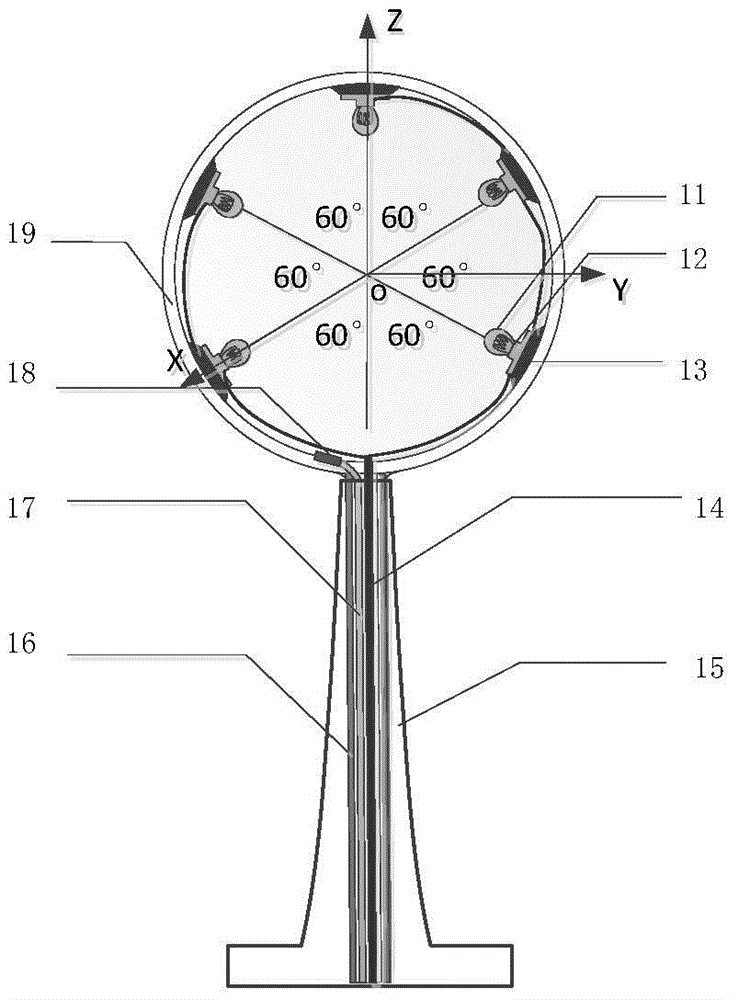

A method for obtaining plume parameters of electric propulsion spacecraft

ActiveCN105067274BHigh sensitivityImprove accuracyGas-turbine engine testingJet-propulsion engine testingPlasma densityPollution

The invention provides an electric propulsion spacecraft plume parameter acquisition method. In a condition of simulating a spacecraft orbit environment, plasma potential, plasma density, electron temperature, plasma ion energy spectrum, electric propulsion plume pollutant deposition and the like, and distribution of space parameters around a thruster are tested; due to use of an oil-free vacuum system, a thin gas atmosphere and a clean environment condition are provided for the method, accuracy of measured data during the test process is greatly enhanced, and an electric thruster test operation risk is reduced; and pollution data in electric thruster multi-parameter diagnosis equipment are measured and acquired, electric propulsion spacecraft plasma plume parameter distribution and a spacecraft in-orbit performance degradation condition in a simulated space environment condition can be estimated, and guidance and basis are provided for research on the electric propulsion spacecraft and service life estimation. The method of the invention is applied to electric propulsion spacecraft engine plume feature test and can be applied to scale test.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

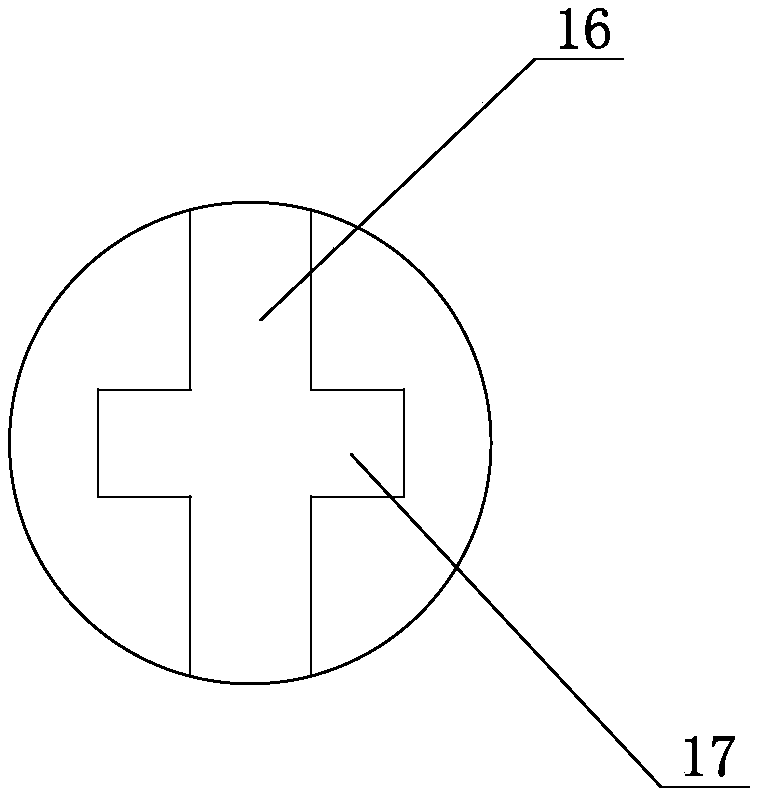

Wire hanging device

The invention relates to a wire hanging device, which comprises a main body bracket, wherein a fixed frame and a movable frame are arranged at the upper end of the main body bracket, a second cleat fork is arranged at the upper end of the fixed frame; a second arc-shaped hook is arranged on the second cleat fork; a first cleat fork is arranged at the upper end of the movable frame, a first arc-shaped hook is arranged on the first cleat fork, a handheld rod and a translation rod are arranged at the lower end of the main body bracket, the translation rod is fixedly connected with the movable frame, a sliding way is formed in the main body bracket, a sliding block sleeves the translation rod, and the sliding block is arranged in the sliding way and used in cooperation with the sliding way. The wire hanging device is novel in structure, convenient to use, capable of lowering the field safety risk level, easy to operate, capable of being operated by one person, small in size and convenientto store and carry; meanwhile, the working time is greatly saved, the cost is reduced, the physical strength of workers is saved, and the test process is more reliable and safer.

Owner:张玉国

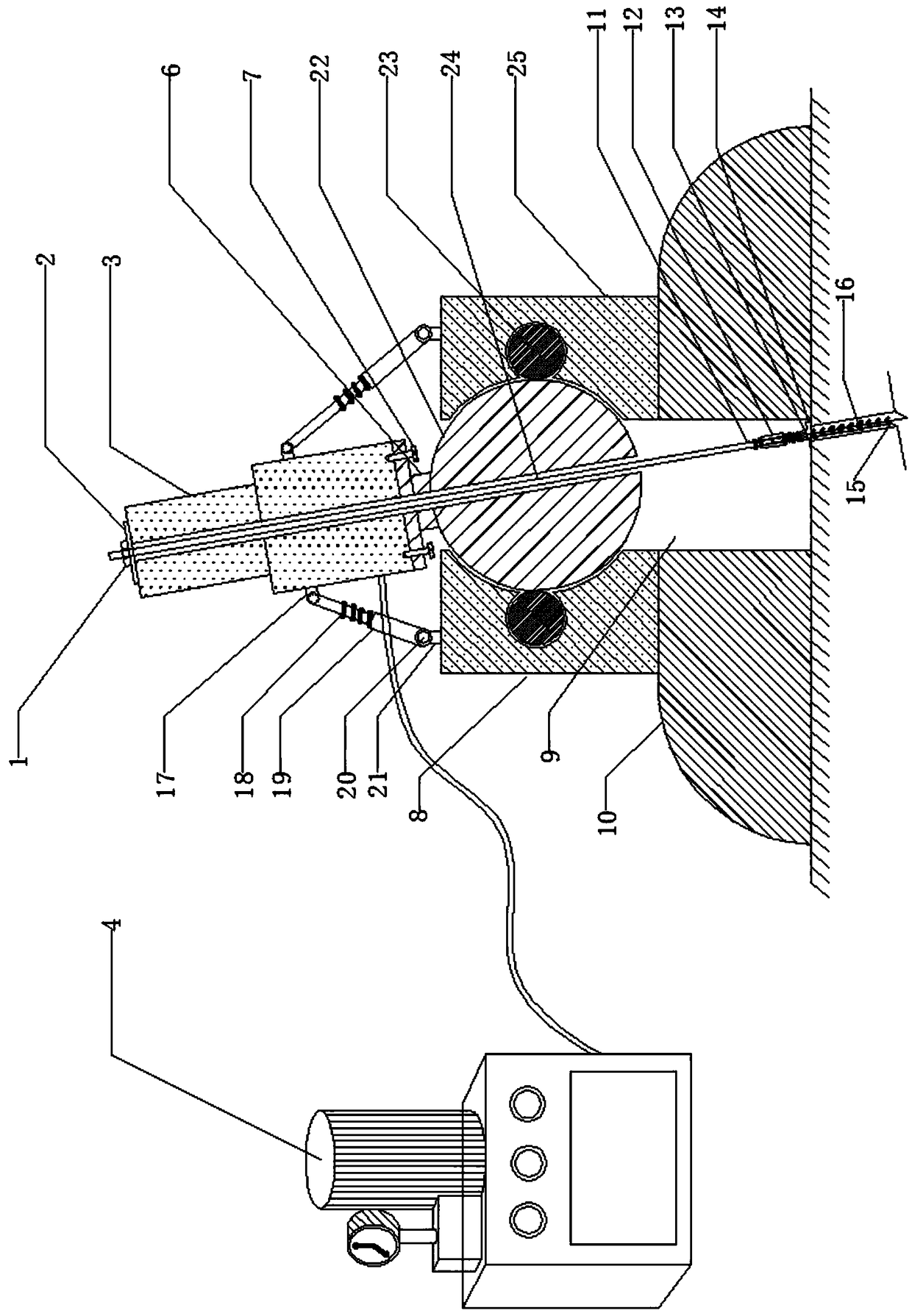

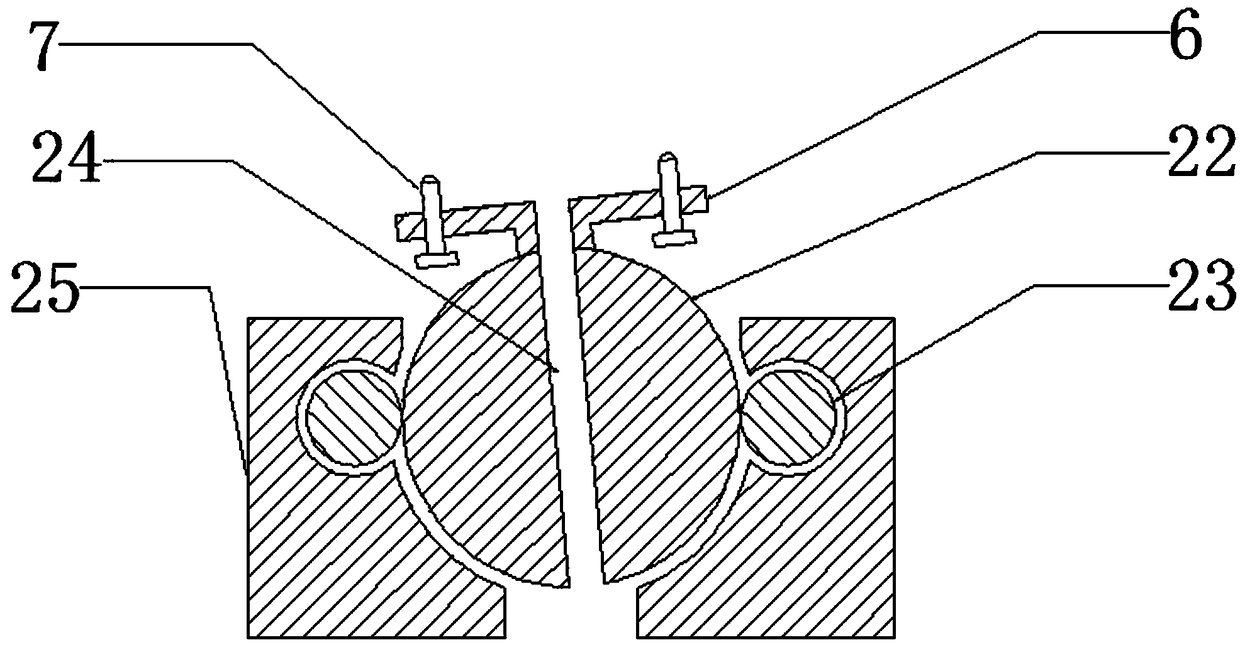

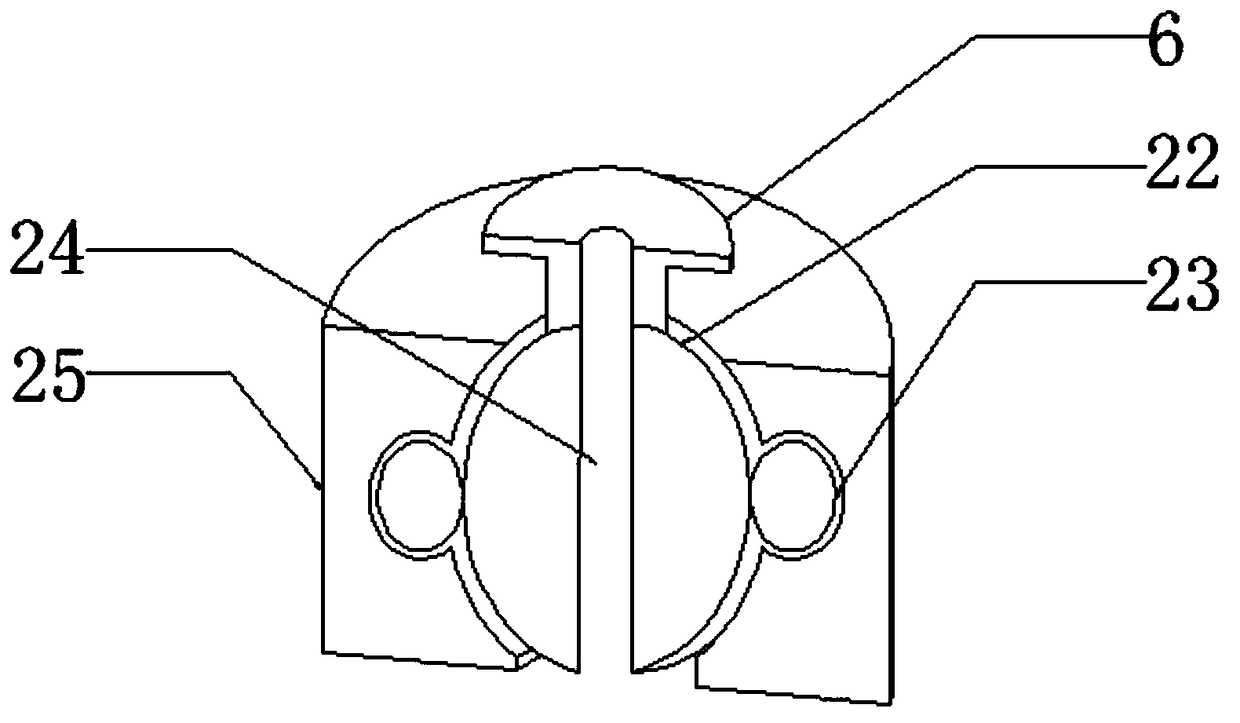

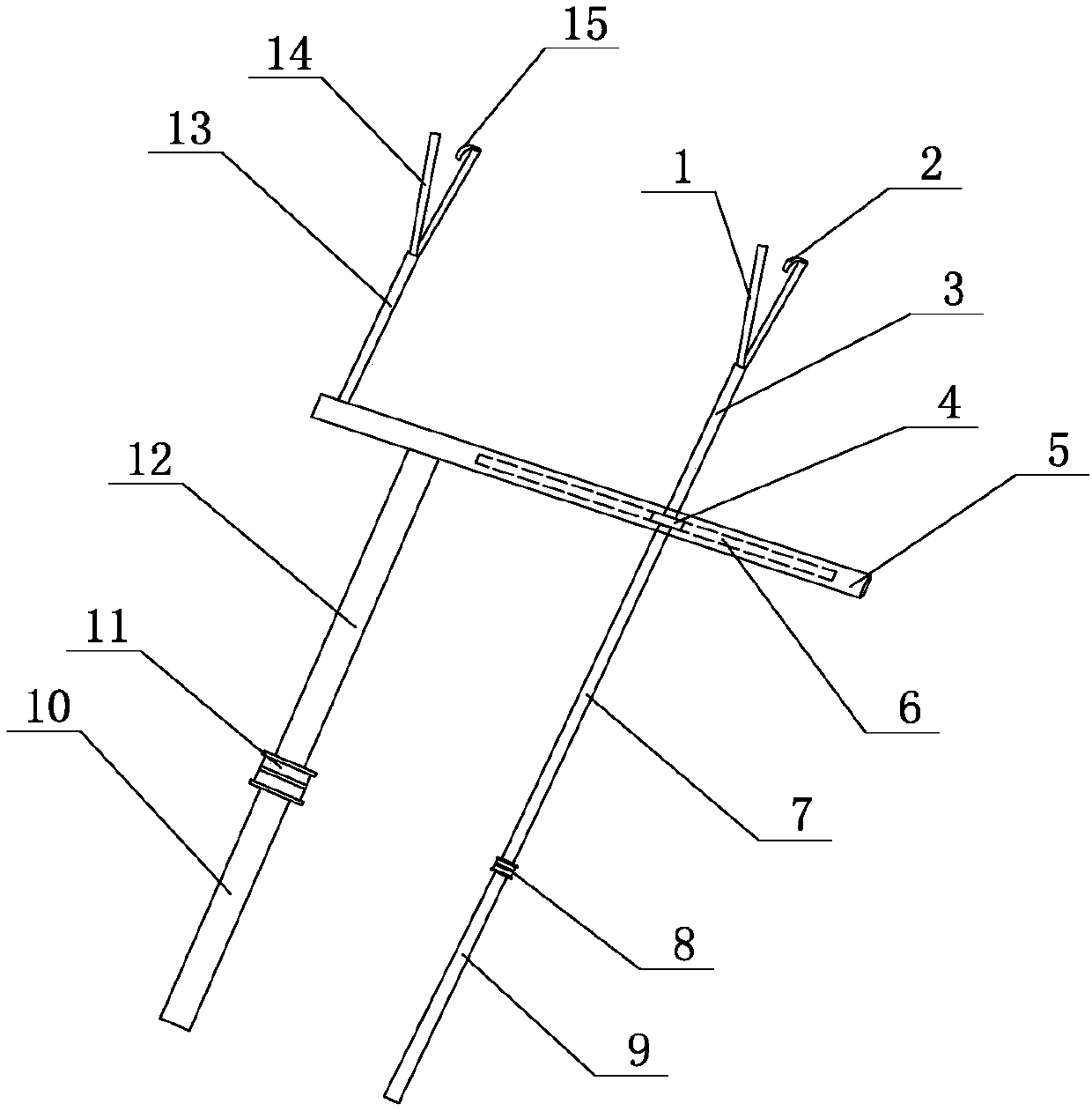

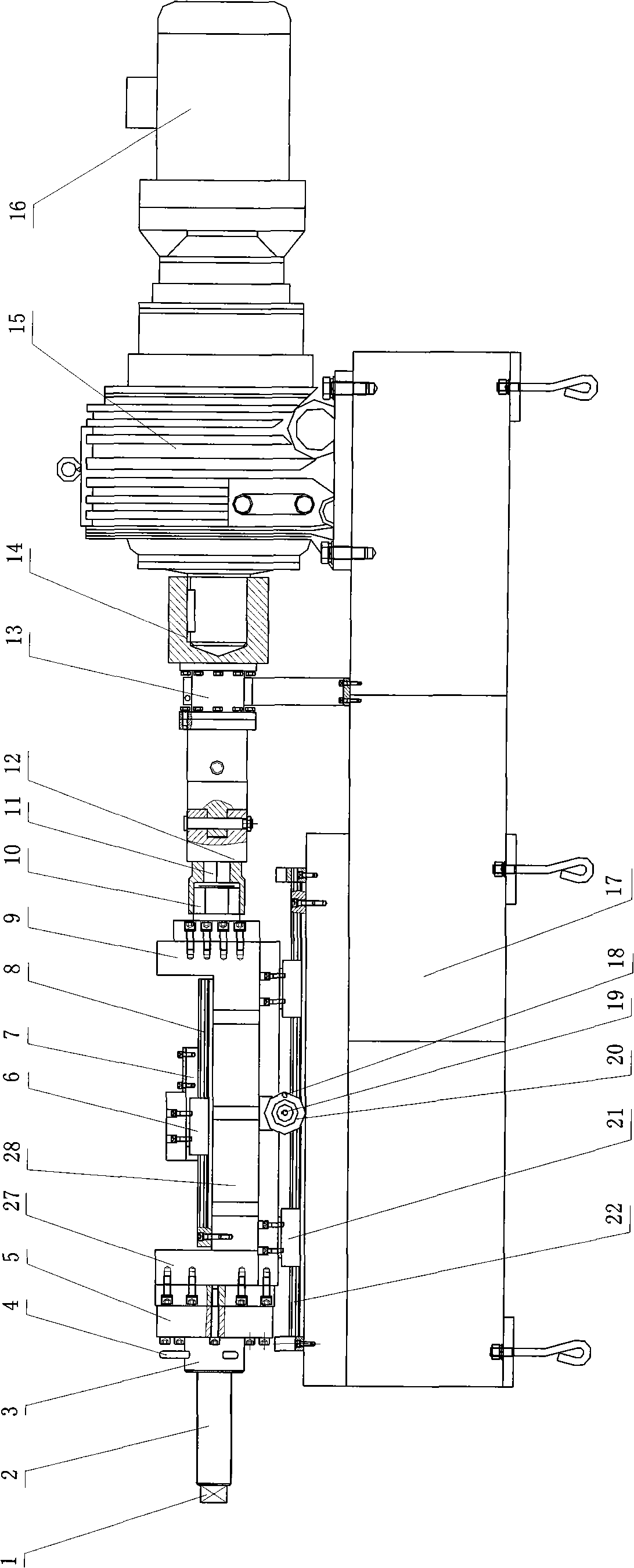

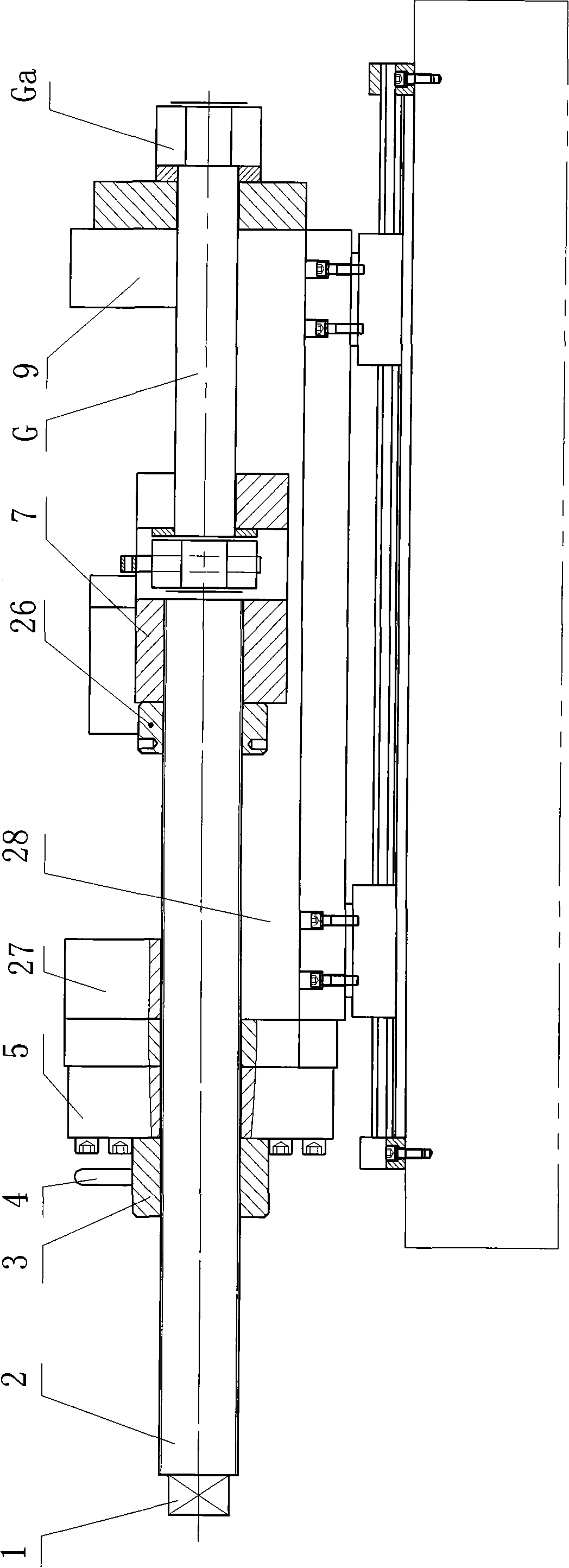

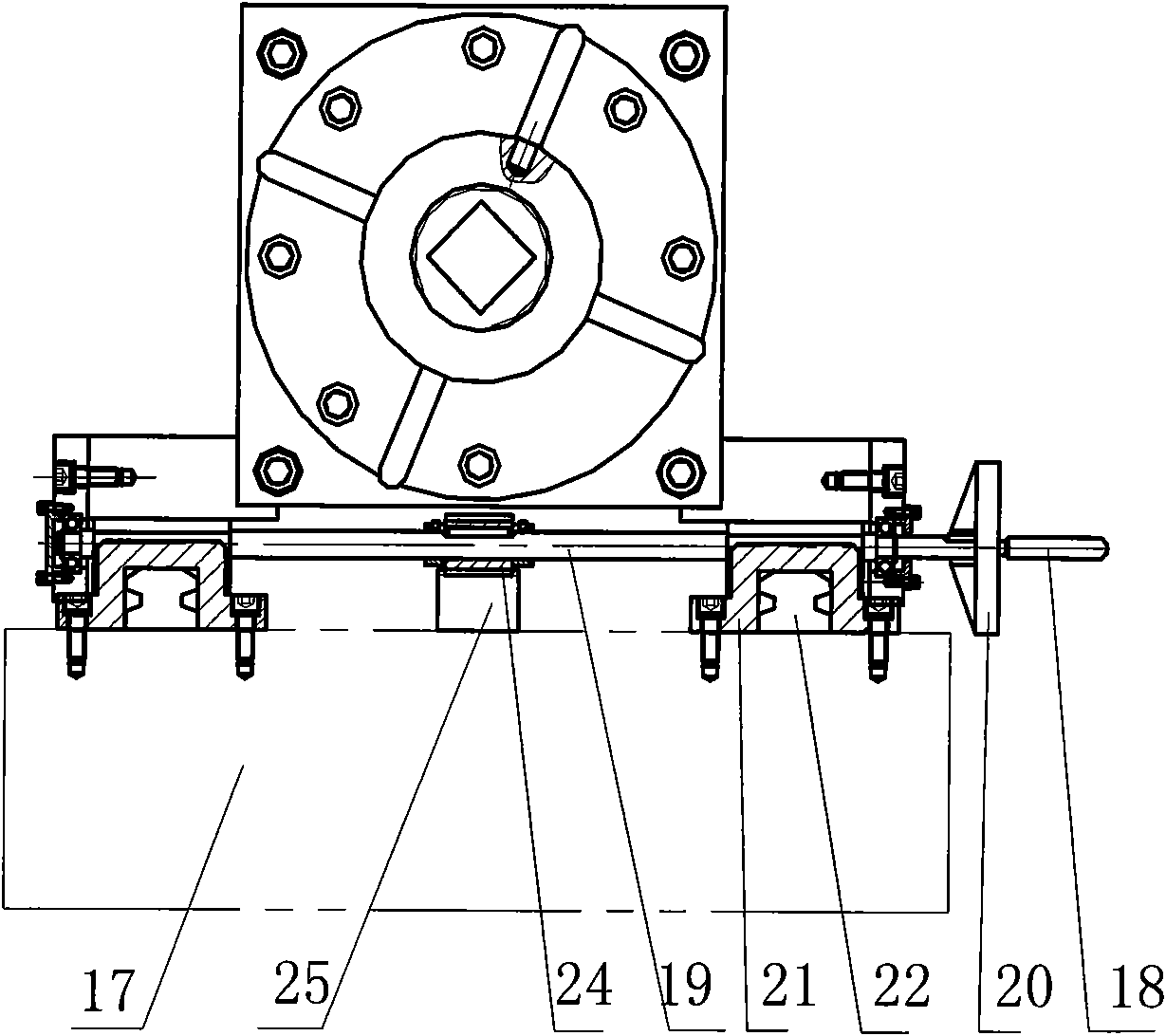

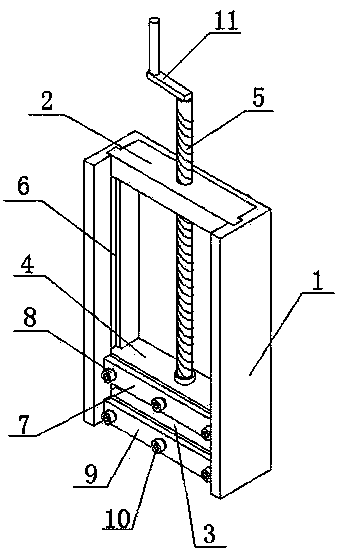

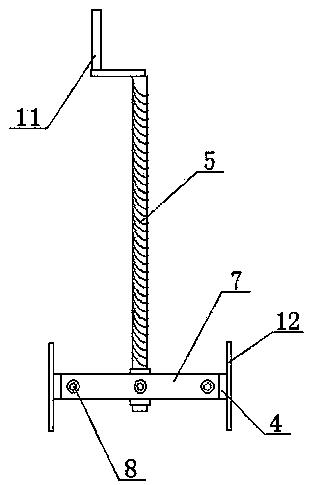

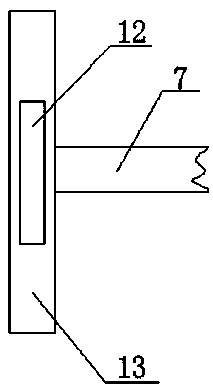

Torque force testing device for large-sized bolt

ActiveCN102262021BRealize fully automatic collectionRealize the display effectMaterial strength using steady torsional forcesCouplingEngineering

The invention belongs to experimental and testing devices for mechanical parts, and specifically relates to a torque force testing device for a large-sized bolt. The device comprises a clamping and fixing part and a twisting part; the clamping and fixing part is formed by the way that two guide rails (22) are arranged on a pedestal (17), left and right guide sleeves (21) are arranged on each guide rail (22), a sliding pull base (28) is formed on the four guide sleeves (21), a bolt pull sleeve (7) is placed in an opening cavity of the sliding pull base (28), and two sides of the bolt pull sleeve (7) are sleeved in sliding rails (8) at two sides of the opening cavity of the sliding pull base (28) via sliding sleeves (6); a front end of a tensioning screw (2) is connected with the bolt pull sleeve (7); a locking screw disc (3) is sleeved on the tensioning screw (2); a rack (25) is arranged on the pedestal (17); and a shaft (19) of a wheel gear (24) engaged with the rack penetrates into the sliding pull base (28). The twisting part is orderly composed of a nut sleeve head (10), a rotary special-shaped head (11), a universal coupling (12), a torque sensor (13), a coupling (14), a reducer (15) and a motor (16). The torque force testing device is steady, reliable, accurate, safe and convenient in the test procedure, and can implement automatic test and improve the speed, the efficiency and the accuracy of the test.

Owner:上海宝冶工程技术有限公司 +1

Automatic sorting machine for lithium batteries

ActiveCN103594733BImprove work efficiencyImprove test efficiencyFinal product manufactureElectrical testingTest efficiencyEngineering

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

A carbon fiber gas cylinder detection line and detection method

InactiveCN105424489BSimple structureCompact structureDetection of fluid at leakage pointDrying using combination processesFiberCarbon fibers

The invention discloses a carbon fiber gas cylinder detection line and a carbon fiber gas cylinder detection method. The detection line includes, in a front-to-back arrangement manner, a water pressure test apparatus, a water pressure auxiliary test apparatus and an air tightness test apparatus. The water pressure test apparatus includes a test rack, a test operation bench, a pressurizing apparatus, a test case installed on the test rack, and test trolleys for stably placing a plurality of to-be-tested gas cylinders. The water pressure auxiliary test apparatus includes a gas cylinder fixture, a transporting trolley, and a gas cylinder water-pouring-away and drying device. The air tightness test apparatus includes an air tightness detection apparatus and a second air supply apparatus for supplying air to the to-be-tested gas cylinders. The air tightness test apparatus is in a cabinet structure or a ground trough structure. The detection method includes the steps of 1) water pressure test; 2) water pouring-away and drying treatment; and 3) air tightness test. The detection line is reasonable in design and simple in operations, is good in use effects, and can easily and quickly complete water pressure test and air tightness test for a plurality of carbon fiber gas cylinders.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

A kind of stretching device and test method for rubber swelling characteristic test

ActiveCN106226508BEnsure movement stabilityGuaranteed motion reliabilityMaterial testing goodsComputer engineeringTest data

The invention discloses a stretching device for rubber swelling property testing and a testing method. The stretching device comprises a frame, a movable plate arranged in the frame, and a rotating mechanism for driving the movable plate to move back and forth. A first clamping mechanism and a second clamping mechanism for clamping the two ends of rubber respectively are correspondingly arranged on the frame and the movable plate. By means of the structure, the position of the movable plate is regulated through the rotating mechanism, and then the distance between the first clamping mechanism and the second clamping mechanism is adjusted to obtain the stretching amount and deformation amount needed by the rubber. Due to the fact that the frame is adopted for restraining the movement locus of the movable plate, the movement stability and reliability of the movable plate are guaranteed, and the reliability of rubber swelling testing data is ensured.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +2

Hydraulic drive type clamping heterotype valve explosion pressure test system and test method

The invention discloses a hydraulic drive type clamping heterotype valve explosion pressure test system and test method. The hydraulic drive type clamping heterotype valve explosion pressure test system includes a hydraulic drive type clamping device, a quick connector plug, an explosion pressure testing device and a monitoring device, wherein the explosion pressure testing device includes a watersupply box, a liquid supply pipe, a pressurization mechanism and a pressure release mechanism. The hydraulic drive type clamping heterotype valve explosion pressure test method includes the followingsteps: 1) preparing before testing; 2) defining a heterotype valve and determining a clamped area of the heterotype valve; 3) determining the number of clamping rods contacting the clamped area; 4) clamping the heterotype valve and connecting a quick connector plug; 5) determining whether clamping of the tested heterotype valve is stable; 6) testing the explosion pressure of the heterotype valve;and dismounting the heterotype valve. The hydraulic drive type clamping heterotype valve explosion pressure test system and test method have the advantages of being reasonable in design, being simplein operation, being stable in clamping of the heterotype valve so as to prevent the heterotype valve from deformation, guaranteeing accuracy of the explosion pressure test of the heterotype valve, and being high in practicality.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com