Method and test device for simulating piston shoe pair friction under high-speed and high-pressure working conditions of plunger pump

A sliding shoe pair and plunger pump technology, which is applied in the field of hydraulic systems, can solve the problems of sliding shoe pair motion mechanism, sliding shoe pair friction working condition simulation and performance testing, which are difficult, and achieve excellent measurability, stable test results, Reliable and accurate results in the testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

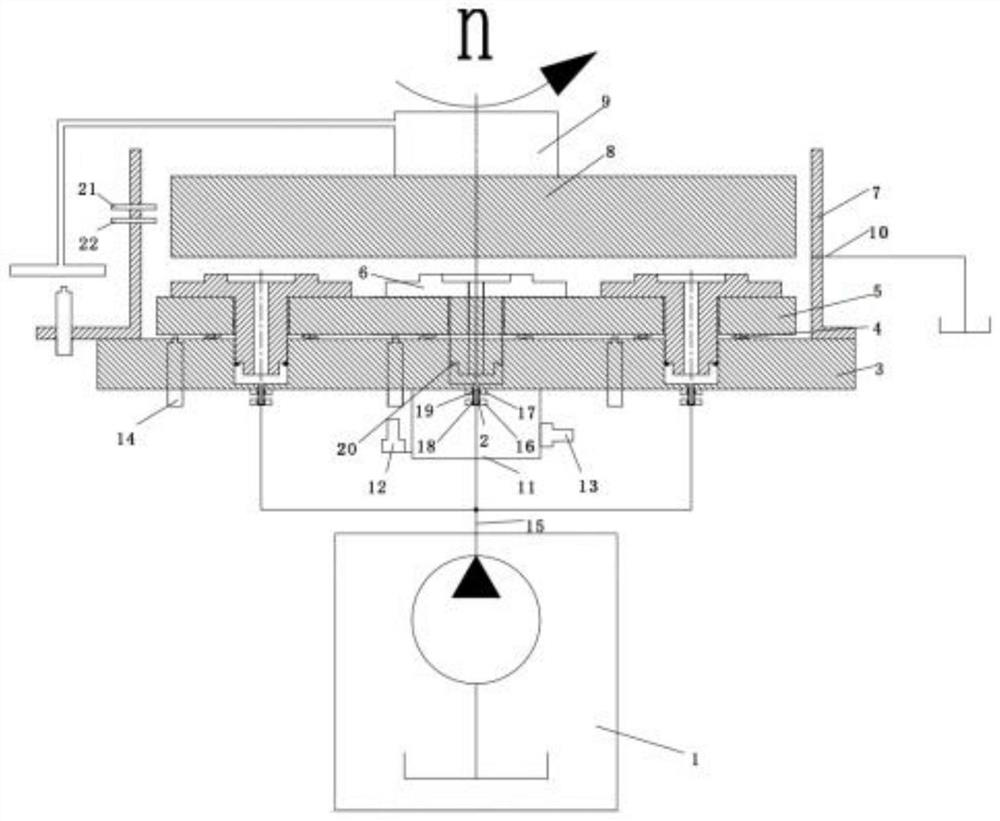

[0062] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

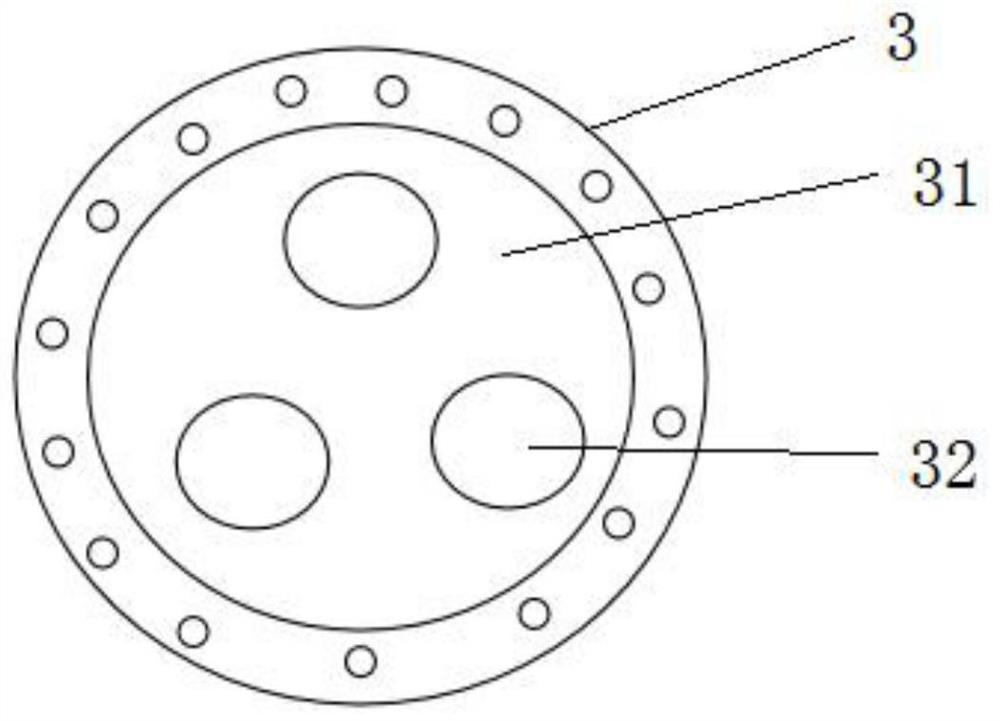

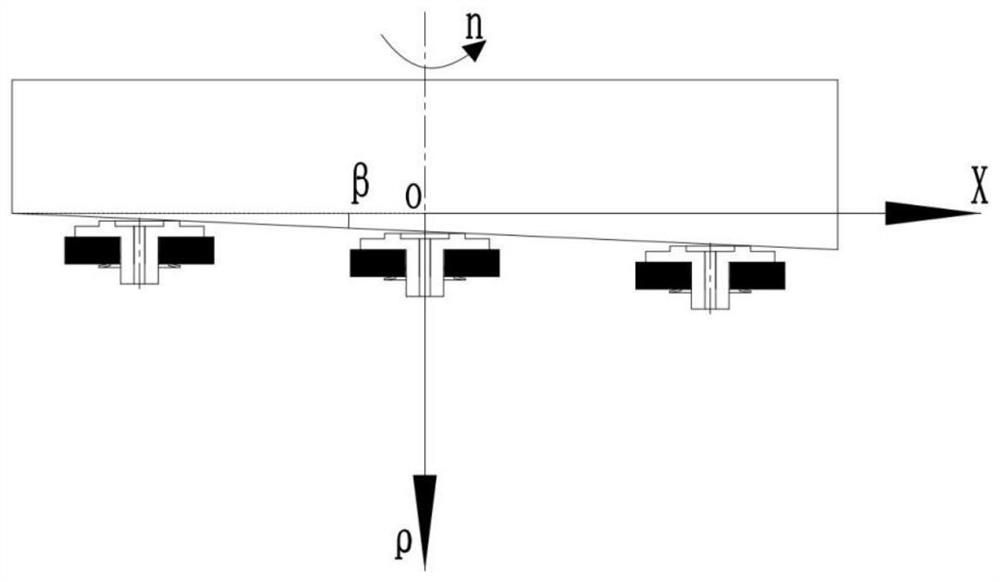

[0063] Such as figure 1 , figure 2 and Figure 7 As shown, the test device of the present invention includes an oil supply pump station 1, a capillary tube 2, a lower clamp 3, a disc spring 4, a floating disc 5, a sliding shoe 6, an oil box 7, an upper test piece 8, and an upper cylinder 9 of a friction and wear testing machine. , the second hydraulic pipeline 10, the lower cylinder 11 of the friction and wear testing machine, the vibration sensor 12, the torque sensor 13, the eddy current displacement sensor 14, the first hydraulic pipeline 15, the first oil circuit block 16, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com