A large-scale bolt torque testing equipment

A technology of torsion testing and testing equipment, which is applied in the direction of applying stable torque to test the strength of materials, etc., can solve the problems of inaccurate test data, hidden engineering problems, small energy levels, and low torque that cannot be tested, and achieve stable testing process. , The effect of convenient operation and rapid development of science and technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

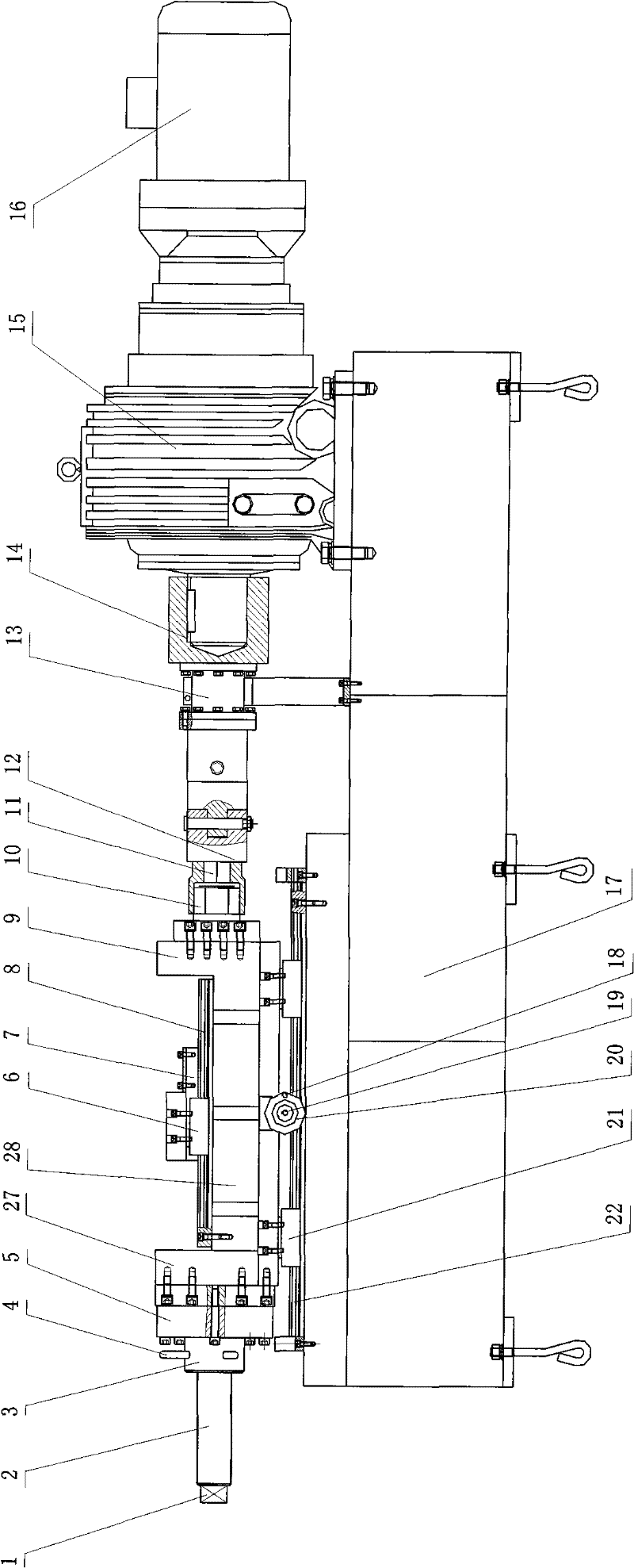

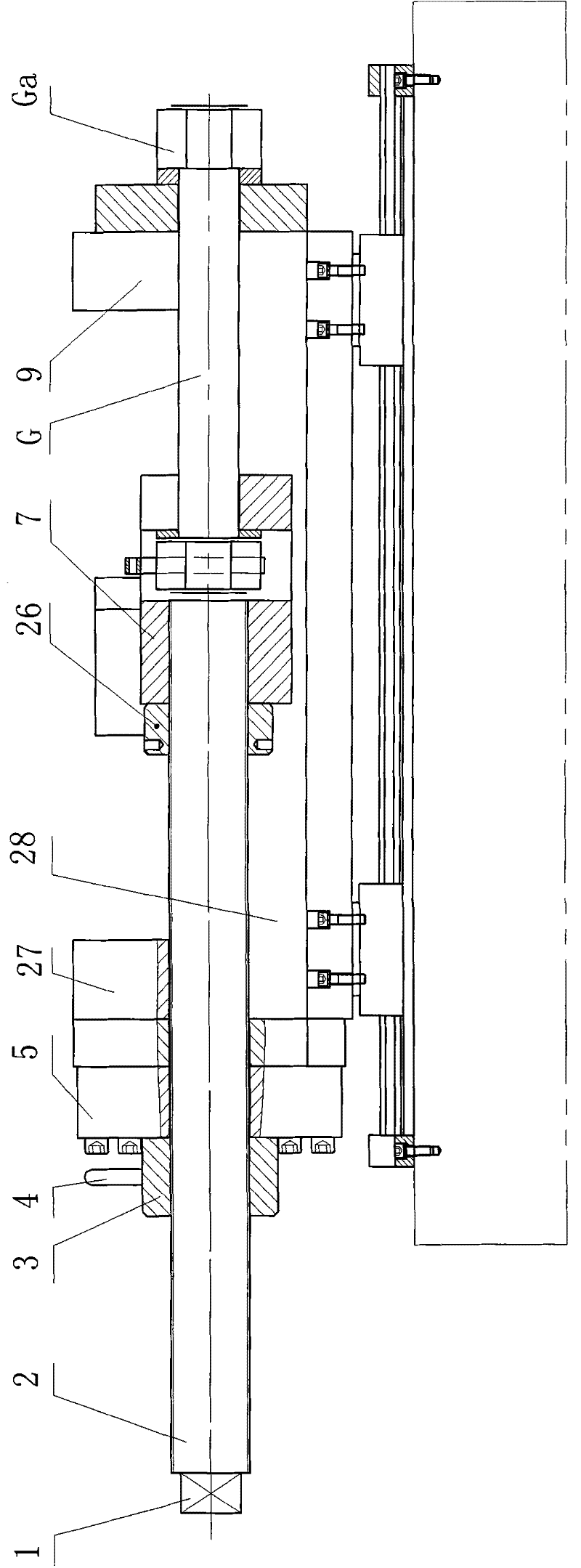

[0031] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] A large-scale bolt torque testing device, characterized in that: the testing device includes clamping and fixing parts and torsion parts arranged on the left and right sides;

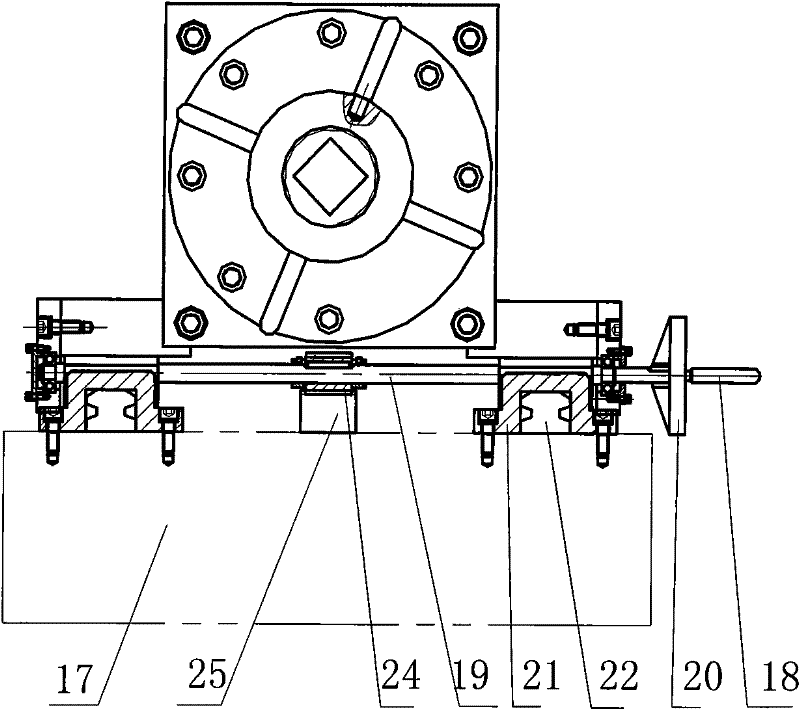

[0033] The clamping and fixing part: on the base 17, two guide rails 22 are arranged in parallel and left and right directions, two left and right guide sleeves 21 are arranged on each guide rail 22, and sliding pull seats 28 are fixedly arranged on four guide sleeves 21, The sliding pull seat 28 is a rectangular cavity with an upward opening, and the two ends are respectively a front baffle 9 and a back baffle 27, and the front baffle 9 offers a bolt circular hole.

[0034] In the opening cavity of the sliding pull seat 28, the bolt pull sleeve 7 is placed, and the both sides of the bolt pull sleeve 7 are slidably set in the slide rails 8 arranged on both sides of the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com