Electric energy gauge seal testing machine

A technology of electric energy meters and testing machines, which is applied in the direction of measuring electric variables, measuring devices, instruments, etc., can solve the problems of no common equipment, etc., and achieve the effects of stable operation, safe testing process, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

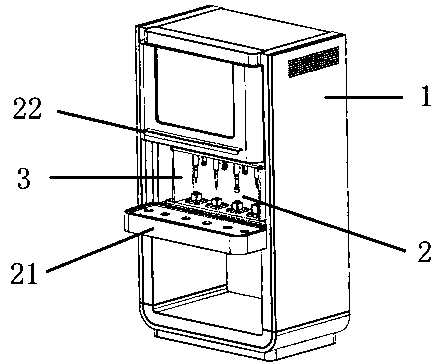

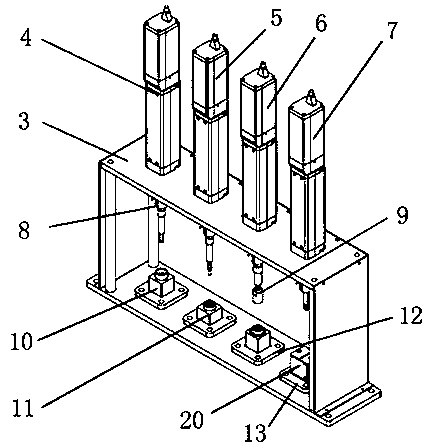

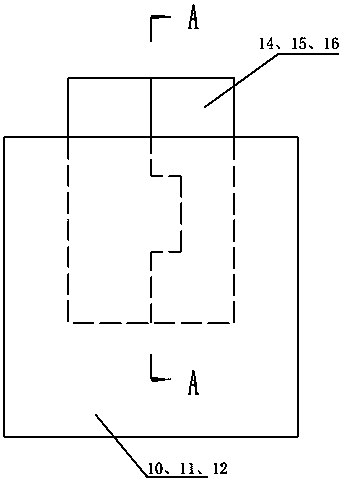

[0015]The electric energy meter seal testing machine includes an upper PC and a lower testing cabinet. The lower testing cabinet includes a cabinet 1. The upper part of the cabinet 1 is an industrial computer connected to the upper PC. The industrial computer includes an integrated The electric control panel, PLC, air switch and relay of the electric control module are installed; the front of the middle part of the cabinet body 1 has a work area 2, and the work area 2 is vertically provided with a test installation frame 3, and the upper part of the test installation frame 3 The first servo electric cylinder 4, the second servo electric cylinder 5, the third servo electric cylinder 6, and the fourth servo electric cylinder 7 that are connected to the industrial computer are vertically pierced. The first servo electric cylinder 4, The ends of the second servo electric cylinder 5, the third servo electric cylinder 6, and the fourth servo electric cylinder 7 are respectively provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com