Silent wear-resistant track of wire and cable repeated bending testing machine

A technology for repeated bending, wire and cable, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying repetitive force/pulsation force, and measuring devices, which can solve the problems of high noise, shortened service life, and operator discomfort and other issues to achieve the effect of reducing noise, increasing service life and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

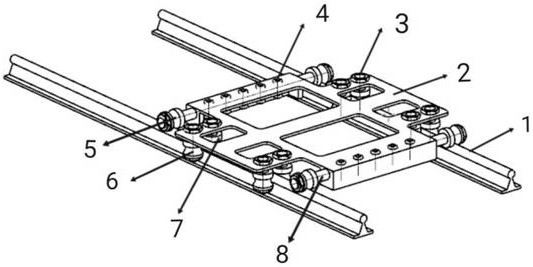

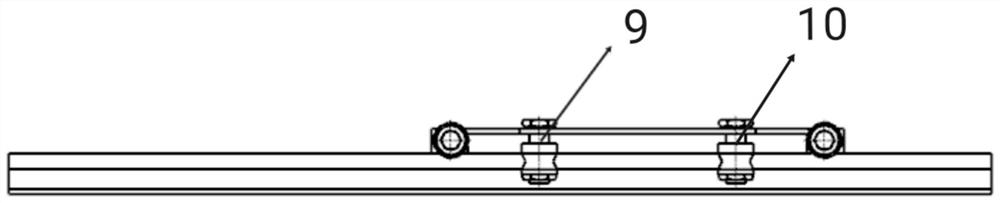

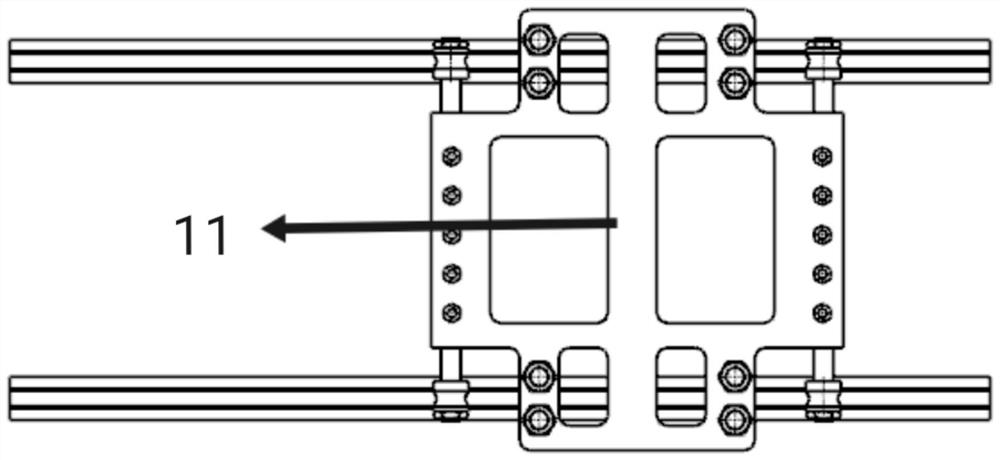

[0028] The silent and wear-resistant track of the wire and cable repeated bending test machine is characterized in that it includes a combined slider and two SBR cylindrical guide rails 1 arranged in parallel, and the combined slider slides on the SBR cylindrical guide rail 1.

[0029] The integral combination slider 11 includes an upper track wheel 5, an outer track wheel 6, an inner track wheel 7, a weight-reducing steel plate 2, a fastening shaft A8, and a fastening shaft B9;

[0030] The integral combination slider 11 is symmetrical to the center, and the outer track wheel 6 and the inner track wheel 7 of the SBR cylindrical guide rail 1 are vertically fastened to the lower surface of the weight-reducing steel plate 2 through the fastening screw A3 and the fastening shaft B9. The track wheel 6 and the inner track wheel 7 play the main sliding role; the upper track wheel 5 of the SBR cylindrical guide rail 1 is fastened to the lower surface of the weight-reducing steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com