A simulated high-speed rotating engine

A high-speed rotation, engine technology, applied in the test of the engine, the test of the internal combustion engine, the test of the machine/structural components, etc., can solve the problems of process danger and low safety factor, and achieve the effect of avoiding explosion and improving the safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description in conjunction with the accompanying drawings, the present invention will be further described.

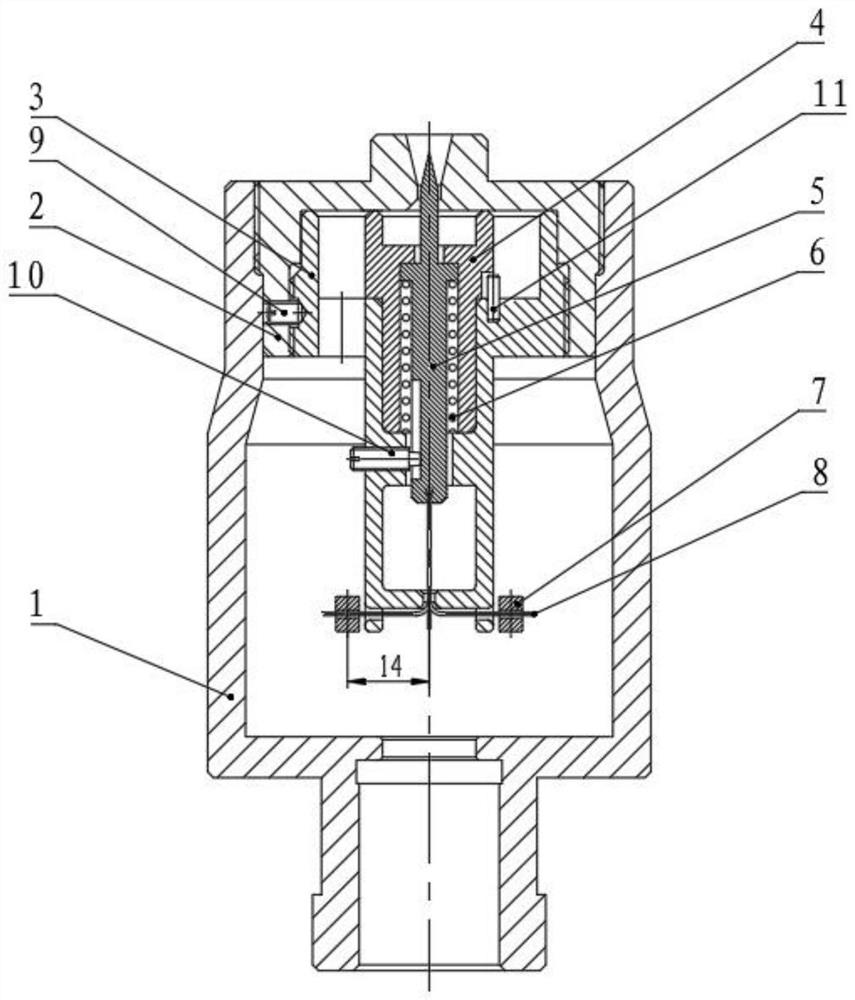

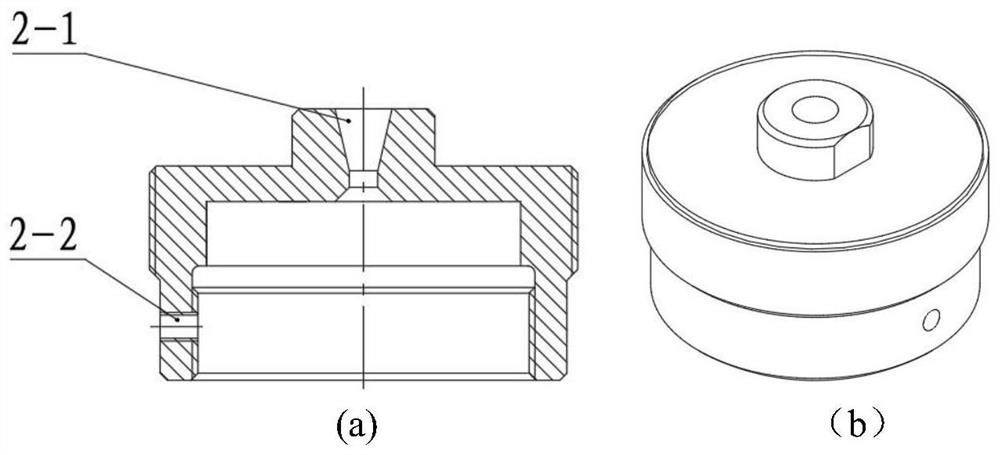

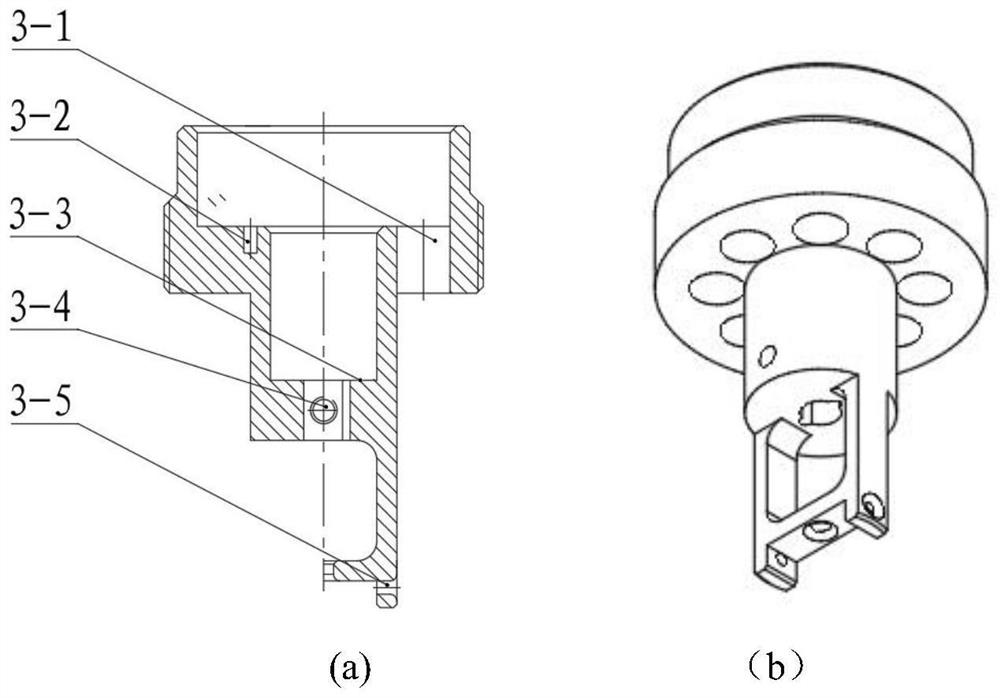

[0022] An analog high speed rotation of the engine, comprising a combustion chamber 1, the cover 2 blocking the rotary hub 3, the fixing sleeve 4, the firing pin 5, the spring 6, two identical cylindrical copper wire 7 the same fish, two 8, the plug cover 2 is fixed to the inner side of the upper end of the combustion chamber 1, 2 is provided at the top center of the plug lid nozzle structure 2-1, the rotating sleeve 3 is disposed inside the cover 2 blocking the rotation of the central hub 3 provided with a spring support seat 3-3, a lower side of the rotating hub 3 through holes symmetrically disposed two earrings 3-5, the stationary sleeve 4 is provided in the rotating hub 3, the firing pin 5 and the fixed 4 coaxially disposed sleeve, the needle 5 penetrate blow to the head fixing sleeve 4 and extends into the nozzle construction 21 against contact w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com