Sorting and grouping method for power lead-acid storage battery set

A lead-acid battery and power technology, applied in lead-acid battery, lead-acid battery construction, secondary battery and other directions, can solve the problems of early capacity attenuation of the pole plate, backward single battery, different amount of active substances, etc. The effect of only lag, improved cycle life, and improved matching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

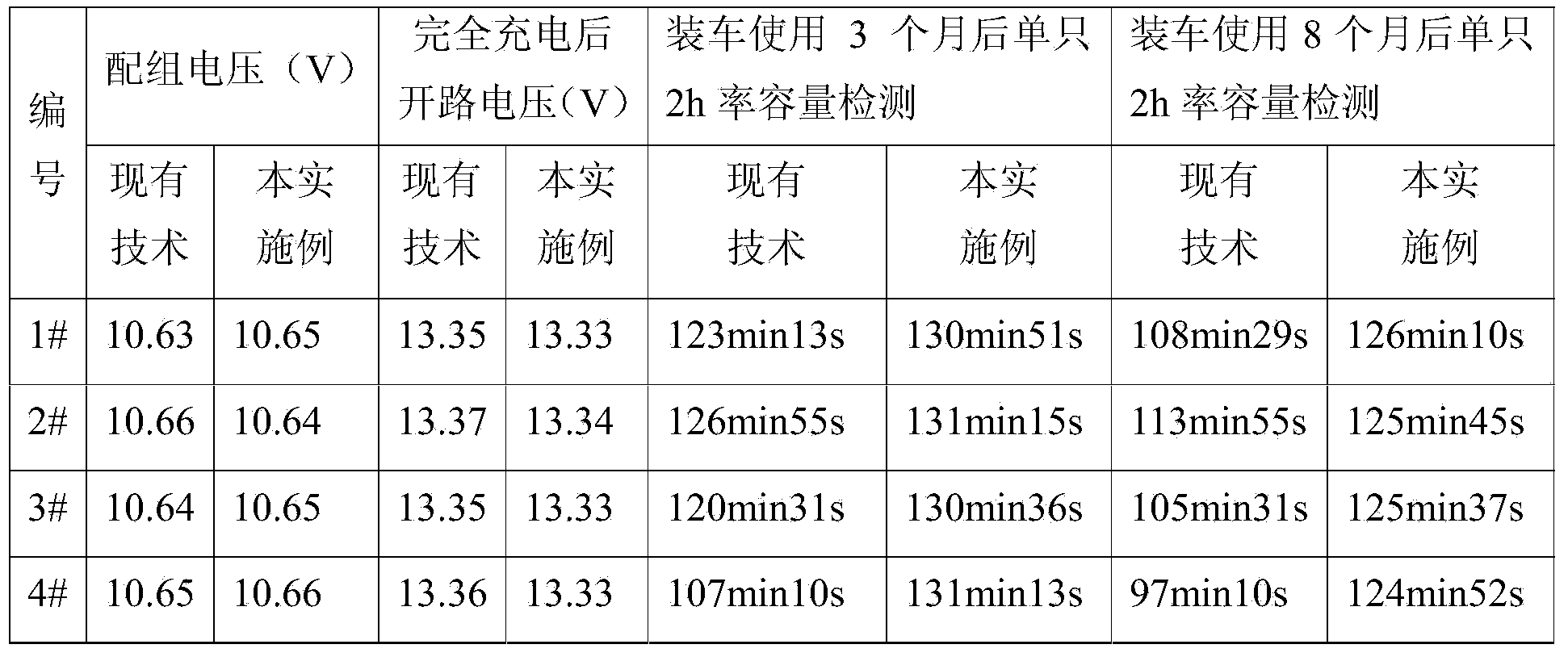

Embodiment 1

[0044] The power lead-acid battery pack of this embodiment is composed of 4 single batteries of the model 6-DZM-12. When matching the group, firstly weigh the polar plates after the externalization treatment, and make the mass difference less than the set value The polar plates are divided into a group and assembled into a single battery, and then assembled into a single battery such as 6V, 12V or 16V according to the needs, and then charge and discharge each single battery, according to the voltage characteristics during the charging and discharging process. Assembling, further assembling the obtained power lead-acid battery pack, specifically includes the following steps:

[0045] S1: Weigh all positive and negative plates, and make the following judgments:

[0046] Positive plate mass in m 1 Indicates that the mass of the negative plate is expressed in m 2 express,

[0047] If 41g≤m 1 ≤43g, it is judged that the positive plate is qualified, otherwise, it is judged that ...

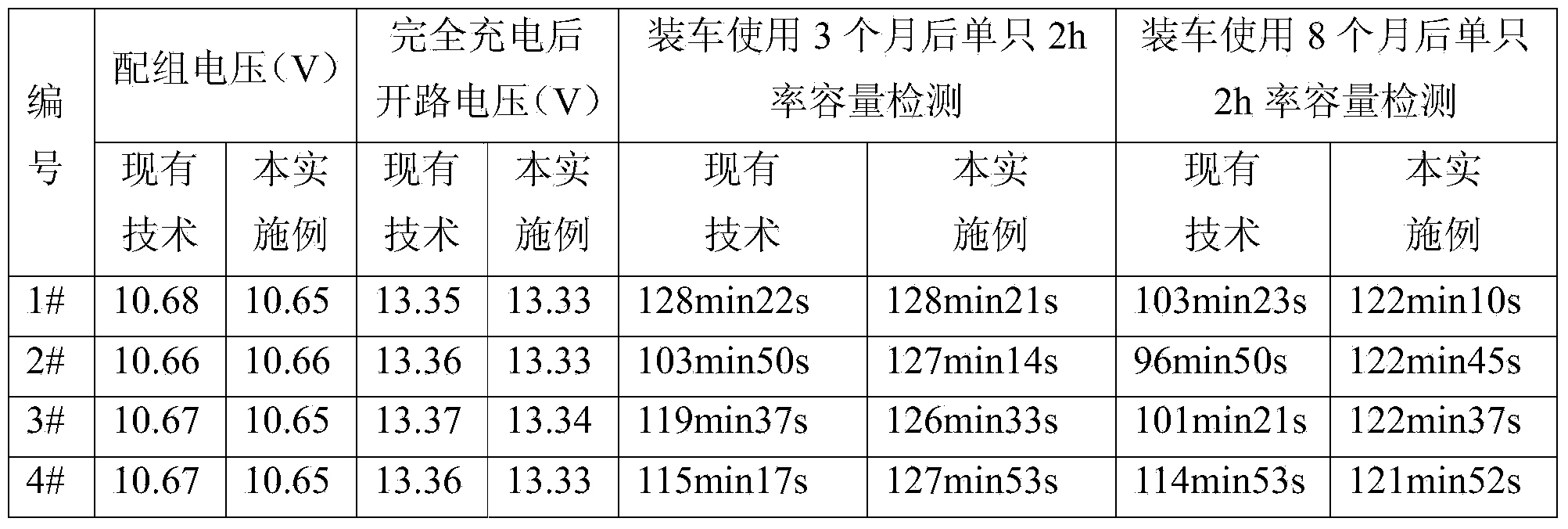

Embodiment 2

[0067] The power lead-acid battery pack of this embodiment is composed of 4 single batteries of the model 6-DZM-20. When matching the group, firstly weigh the polar plates after the externalization treatment, and make the mass difference less than the set value The plates are divided into a group and assembled into a single battery, and then assembled into a single battery such as 6V, 12V or 16V according to the needs, and then charge and discharge each single battery according to the voltage characteristics during the charging and discharging process. Assembling, further assembling the obtained power lead-acid battery pack, the specific steps included are the same as in Example 1, the difference is that the charging and discharging process in step S3 includes:

[0068] (1) Stand still for the first time, and the standing time is 2 hours;

[0069] (2) For the first charge, the charging time is 3 hours, the charging current is 2.5A, and the charging capacity is 7.5Ah;

[0070]...

Embodiment 3

[0081] The power lead-acid battery pack of this embodiment is composed of 4 single batteries of the model 6-EVF-24. When matching the group, firstly weigh the polar plates after the externalization treatment, and make the mass difference less than the set value The polar plates are divided into a group and assembled into a single battery, and then according to the needs, select 6 single batteries and assemble them into a single battery such as 12V, and then charge and discharge each single battery, according to the voltage during the charging and discharging process The characteristics are matched and grouped, and the power lead-acid battery pack obtained is further assembled. The specific steps included are the same as those in Example 1, except that the charging and discharging process in step S3 includes:

[0082] (1) Stand still for the first time, and the standing time is 2 hours;

[0083] (2) For the first charge, the charging time is 3 hours, the charging current is 3A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com