Positioning tool for blowing air-outlet elbow of dust collector

A technology of air outlet elbow and positioning tooling, applied in auxiliary devices, manufacturing tools, metal processing, etc., can solve the problems of rework cutting, affecting the appearance and quality, and the size of the injection outlet elbow cannot be positioned, so as to achieve convenient assembly , less consumables, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

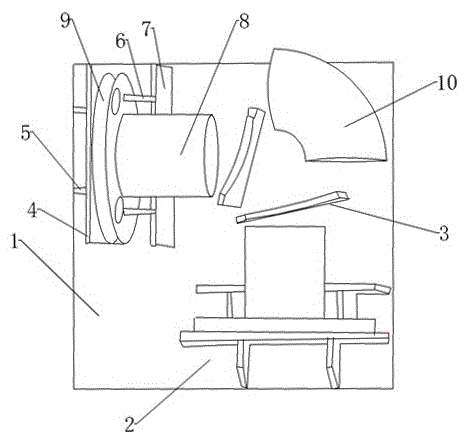

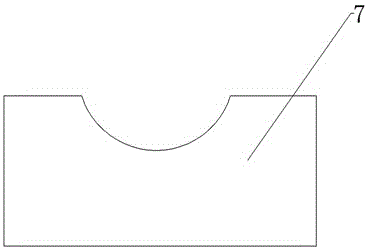

[0013] Such as figure 1 with figure 2 As shown, the dust collector blows out the air elbow positioning tool, including the bottom steel plate 1, the clamp 2 and the support groove 3, and the two clamps 2 are located on the upper surface of the bottom steel plate 1, and the bottom steel plate 1 can be a square steel plate, two The clamps 2 are perpendicular to each other in the axial direction, and the clamps 2 are composed of a fixed plate 4, a support block 5, a fixed block 6 and a fixed groove 7, and the fixed plate 4 and the fixed groove 7 are arranged oppositely, and the fixed plate 4 and the fixed groove 7 are arranged oppositely. The bottom edge of the fixing groove 7 is welded on the upper surface of the bottom steel plate 1 , and the two supporting grooves 3 are located between the two clamps 2 and are evenly welded on the bottom st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com