A thermal processing automatic cylinder clamping mechanism

A clamping mechanism and thermal processing technology, used in workpiece clamping devices, manufacturing tools, etc., can solve problems such as inability to achieve automatic cooling, short cylinder life, and side-to-side clamping of the clamp, achieving long life and reducing material loss costs. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

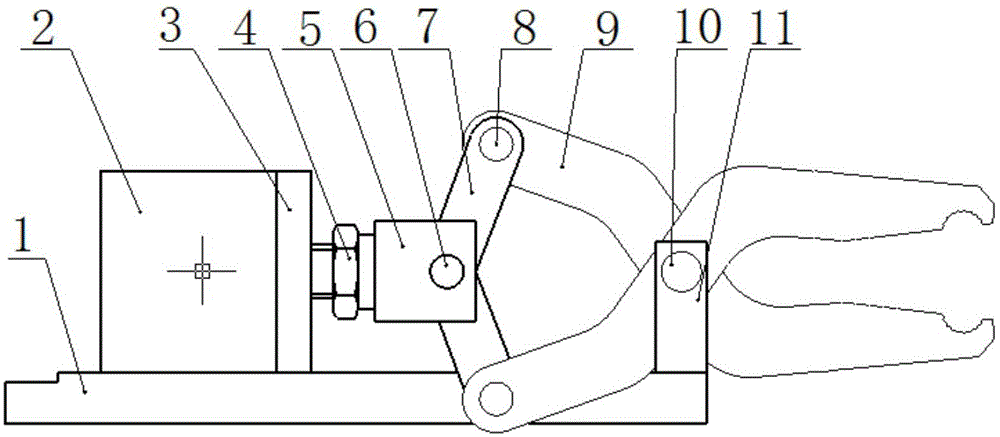

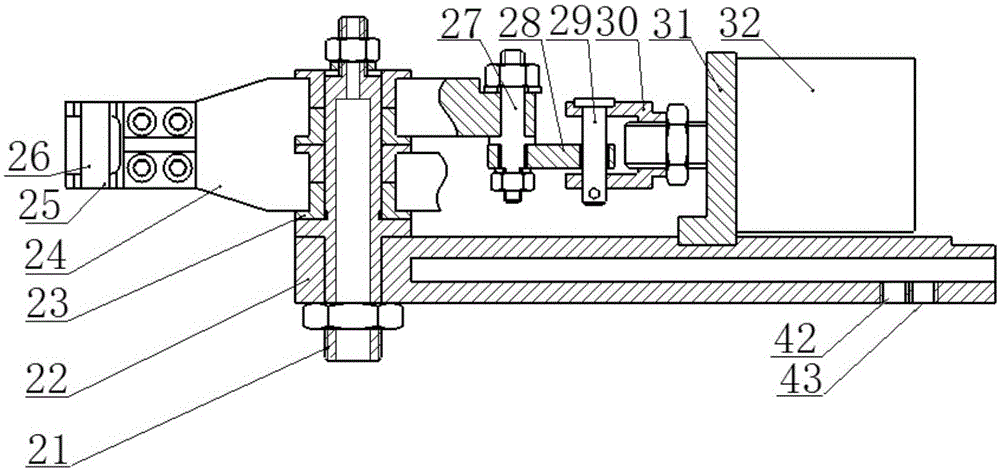

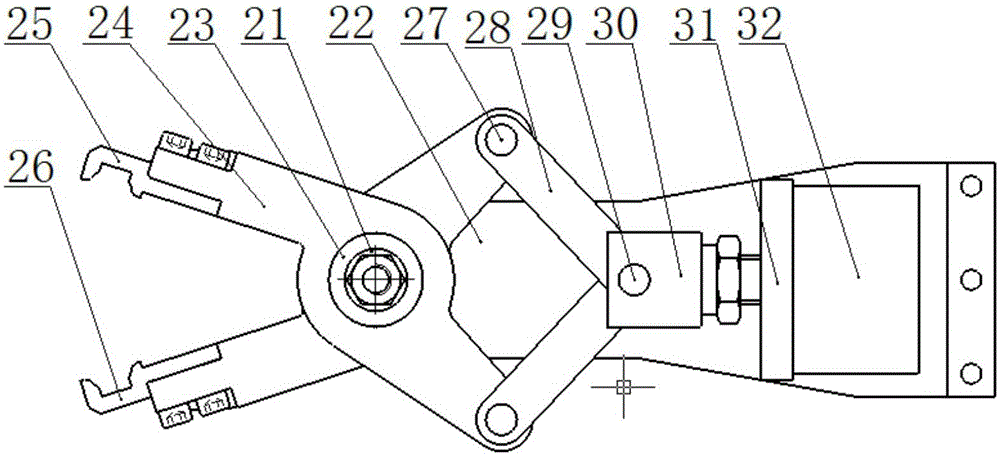

[0022] A thermal processing automatic cylinder clamping mechanism, such as figure 2 and image 3 As shown, it includes: main shaft 21, main support 22, bearing 23, rotating support 24, upper material clamp 25, lower material clamp 26, connection pins 27 and 29, connection block 28, connection seat 30, cylinder support 31, cylinder 32 etc., where:

[0023] The main shaft 21 and the cylinder support 31 are installed on the two ends of the main bracket 22 respectively, and the rotating bracket 24 is assembled on the main shaft 21 through the bearing 23; (In order to facilitate the replacement of the clip after wear, screw assembly can be used); the connection end of the rotating bracket 24 is connected to the connection block 28 through the connection pin 27; the connection block 28 is connected to the connection seat 30 through the connection pin 29; the connection seat 30 It is connected with the cylinder support 31, and the cylinder 32 is installed on the cylinder support 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com