Flush piping system, oxygen generator and their respective control methods

A technology for flushing pipeline systems and pipelines, which is applied in the fields of flushing pipeline systems, oxygen generators and their respective control fields, which can solve the problems of excessive flushing of exhausted tanks, oxygen waste, etc., and avoid shutdown work, increase oxygen production, and avoid the effect of normally open through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

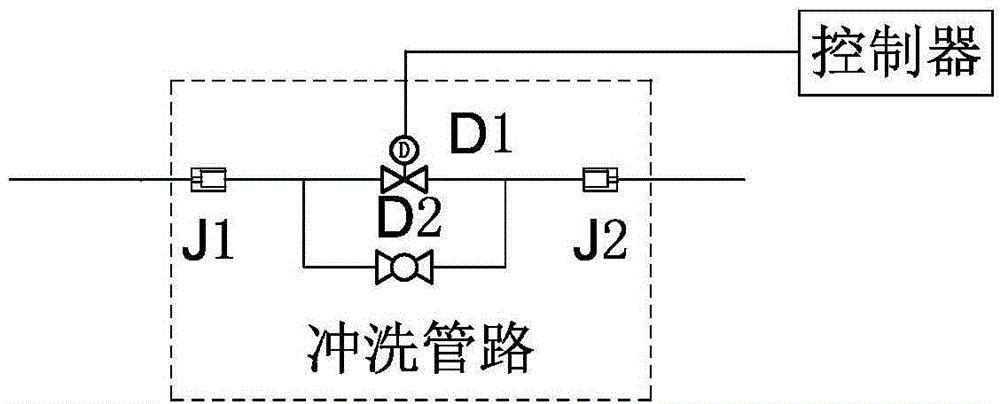

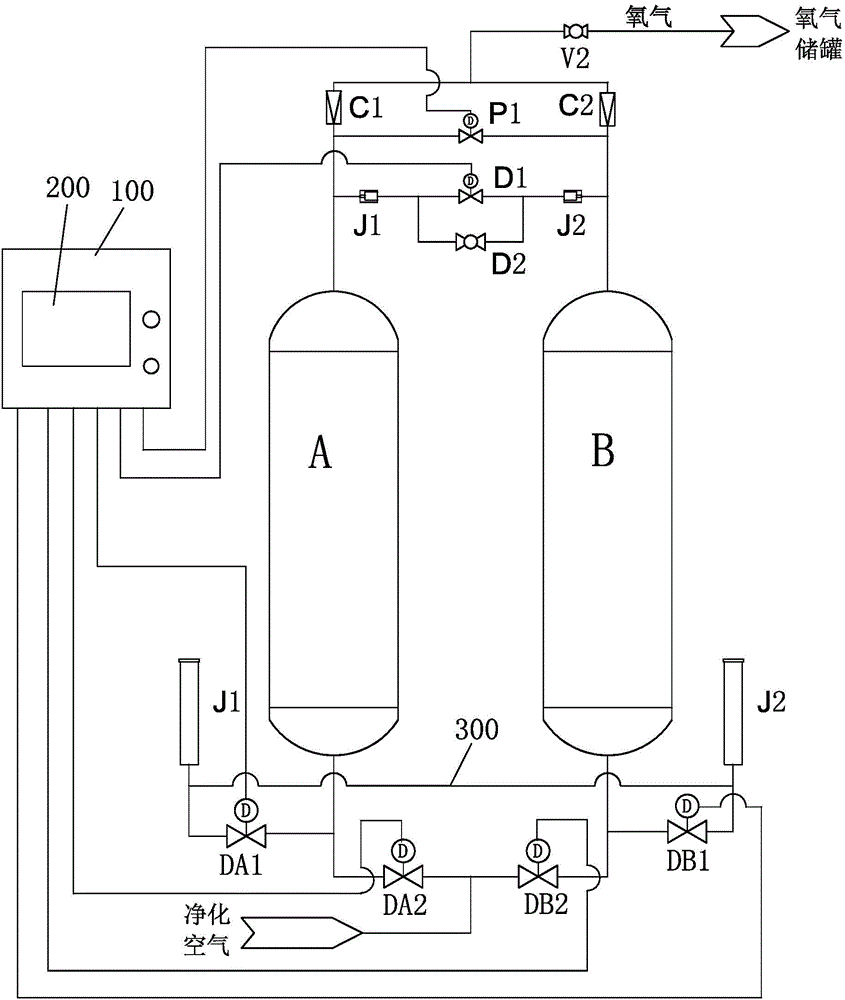

[0042] Such as figure 2 As shown, the flushing pipeline system includes the controller and the flushing pipeline. The flushing pipeline includes the first throttle J1, the electronically controlled adjustable valve D1, and the second throttle J2 connected in sequence from left to right. A manual adjustable valve D2 is connected between the two ends of the adjustable valve D1; the controller is connected to the electrically controlled adjustable valve D1. The manual adjustable valve D2 is convenient for manual adjustment when the electronically controlled adjustable valve D1 is not working normally; when the electronically controlled adjustable valve D1 is working normally, the manually adjustable valve D2 is in the closed state.

[0043] The electrically controlled adjustable valve D1 can be an angle seat solenoid valve or a pilot solenoid valve or a digital regulating valve or a proportional valve or other two-way solenoid valves.

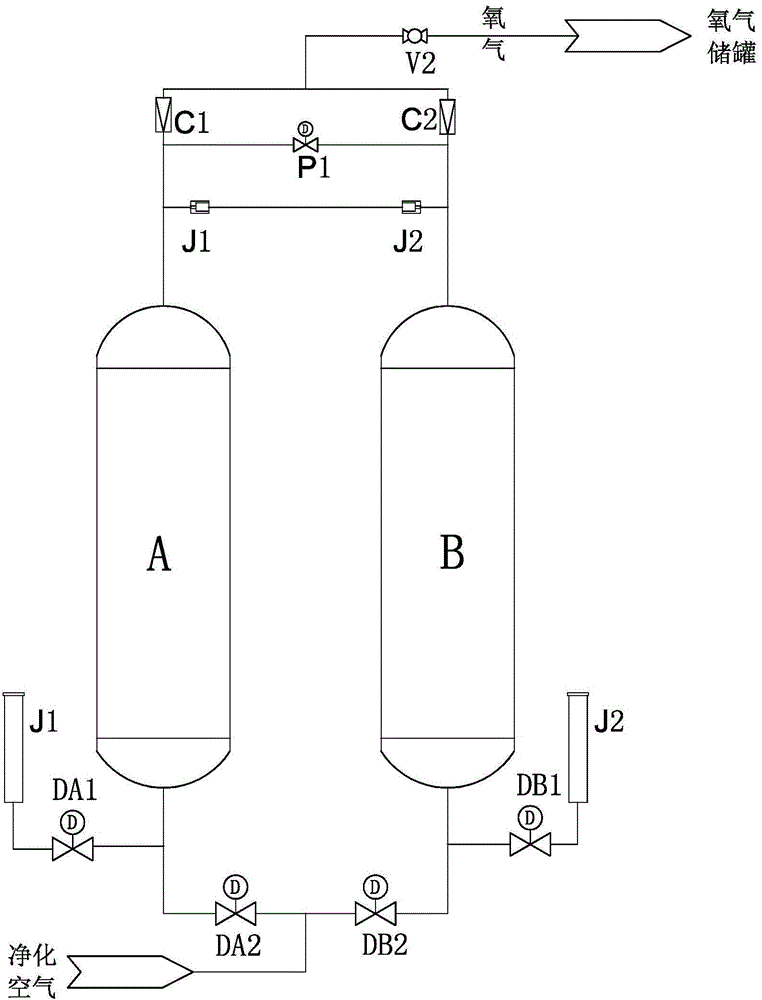

[0044] The flushing pipeline system is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com