A bonding method for a hyperboloid reflective mirror of a sunlight collector for solar thermal power generation

A solar thermal power generation and collector technology, which is applied in the field of solar thermal power generation, can solve the problems that the surface accuracy of the hyperboloid reflector cannot meet the surface profile accuracy, the processing efficiency is low, and the investment cost of the molding die is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

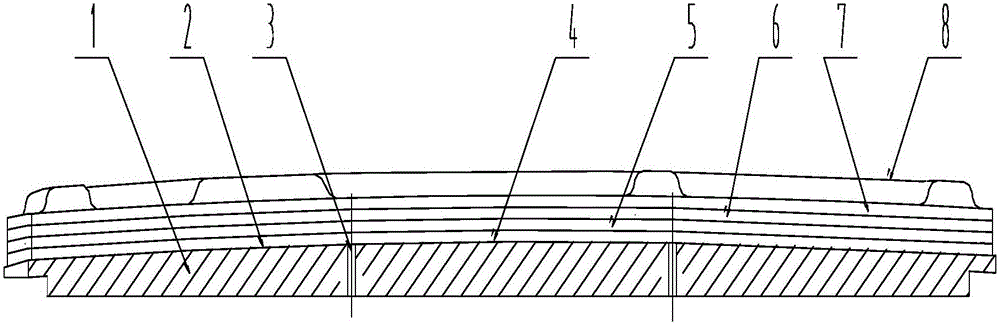

Embodiment 1

[0015] Example 1, the reflective lens with the smallest area, the outer dimension is 1480mmx815mm, the outer dimension of the bonding mold 1 is 3mm wider than the outer outline of the reflective lens by 3mm, vacuumize to -0.1MPa, heat to 120°C, keep warm for 1h and then follow the furnace Cool to room temperature. Bond the metal back plate 8 and let it stand at room temperature for at least 6 hours. After bonding and molding on the bonding mold 1, the hyperboloid profile of the mirror paraboloid is within 0.9 mm, and the diameter of the focused spot is less than 140 mm, and one piece is bonded every 10 hours. At the same time, 4 sets of bonding molds are used for processing, and 8 pieces can be bonded every 24 hours.

Embodiment 2

[0016] Example 2, a reflective lens with a small area, the outer dimension is 1464mmx922mm, the outer dimension of the bonding mold 1 is 4mm wider than the outer outline of the reflective lens by 4mm, vacuumize to -0.1MPa, heat to 130°C, keep warm for 1h and then The furnace was cooled to room temperature. Bond the metal back plate 8 and let it stand at room temperature for at least 6 hours. After bonding and forming on the bonding mold 1, the hyperboloid profile of the mirror paraboloid is within 1 mm, and the diameter of the focused spot is less than 150 mm, and one piece is bonded every 10 hours. At the same time, 8 sets of bonding molds are used for processing, and 16 pieces can be bonded every 24 hours.

Embodiment 3

[0017] Example 3, the reflective lens with the largest area, the outer dimension is 1440mmx1344mm, the outer dimension of the bonding mold 1 is 8mm wider than the outer outline of the reflective lens by 8mm, vacuumize to -0.08MPa, heat to 140°C, keep warm for 1.5h and then The furnace was cooled to room temperature. Bond the metal back plate 8 and let it stand at room temperature for at least 8 hours. After bonding and forming on the bonding mold 1, the hyperboloid profile of the mirror parabola is within 1.3 mm, and the diameter of the focused spot is less than 180 mm, and one piece is bonded every 16 hours. At the same time, 4 sets of bonding molds are used for processing, and 4 pieces can be bonded every 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com