A catalyst capable of reducing the curing temperature of saturated polyester resins with carboxyl groups

A technology of polyester resin and curing temperature, which is applied in the catalyst of saturated polyester resin curing temperature and its preparation field, can solve the problems of poor decoration of powder coatings, easy occurrence of true pore bubbles, and disappearance of decorative functions, and achieve convenient operation, The effect of promoting leveling and reducing melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

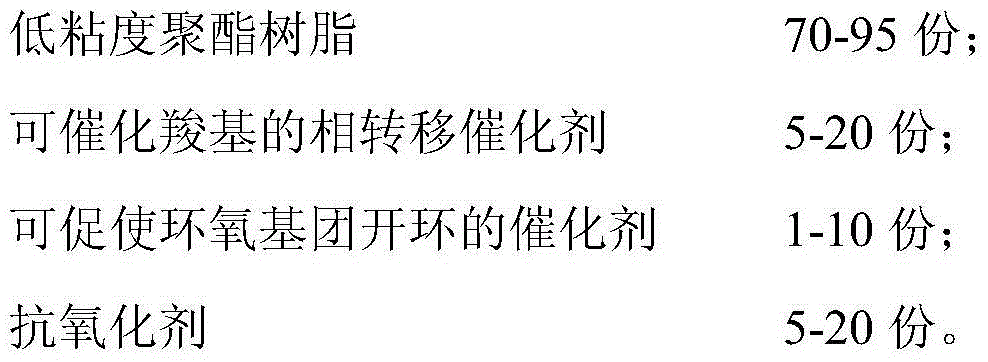

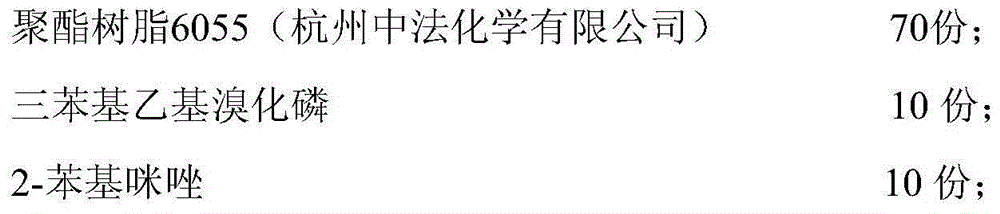

[0032] A catalyst capable of reducing the curing temperature of saturated polyester resins with carboxyl end groups. The raw material constituents and their weights are as follows:

[0033]

[0034]

[0035] The steps of the above catalyst preparation method are as follows:

[0036] Put the polyester resin 6055 into the reactor, let it melt and stir at the temperature of 170-180℃, and then separate the triphenylethylphosphonium bromide, 2-phenylimidazole and antioxidant 1010 (in any order) Add it to the melted polyester resin, stir uniformly for 20 minutes, cool and press, and finally form a milky white transparent solid, that is, catalyst A that can reduce the curing temperature of the saturated polyester resin with carboxyl end groups.

[0037] Method of use: The obtained catalyst A can be added to the powder coating formulation at a mass fraction of 0.1%-5% according to the curing temperature of the powder coating.

Embodiment 2

[0039] A catalyst capable of reducing the curing temperature of saturated polyester resins with carboxyl end groups. Its raw material constituents and their weights are as follows:

[0040]

[0041] The steps of the above catalyst preparation method are as follows:

[0042] Add various materials to the high-speed mixer, dry-mix and extrude through the extruder. The temperature in the first zone is 80-90℃, and the temperature in the second zone is 100-120℃. Melt, mix, extrude and cool , Tablets, become flake-like milky white solid, that is, catalyst B can reduce the curing temperature of saturated polyester resin with carboxyl end groups.

[0043] Method of use: The obtained catalyst B can be added to the powder coating formulation at a mass fraction of 0.1%-5% according to the curing temperature of the powder coating.

Embodiment 3

[0045] A catalyst capable of reducing the curing temperature of saturated polyester resins with carboxyl end groups. Its raw material constituents and their weights are as follows:

[0046]

[0047] The preparation method of the above-mentioned catalyst is the same as that of Example 1, and the catalyst C which can reduce the curing temperature of the saturated polyester resin with carboxyl end groups is obtained.

[0048] Method of use: The obtained catalyst C can be added to the powder coating formulation at a mass fraction of 0.1%-5% according to the curing temperature of the powder coating.

[0049] Actual application effect and test situation of the powder coating of the present invention:

[0050] In order to test the actual application effect of the catalyst of the present invention, the specific operation is as follows: Add the catalysts A, B and C prepared in the examples into the powder coating formula in a certain amount, as shown in Table 1, the curing temperature and level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com