Selective oxidation-reduction method for recycling arsenic and antimony from arsenic-antimony smoke

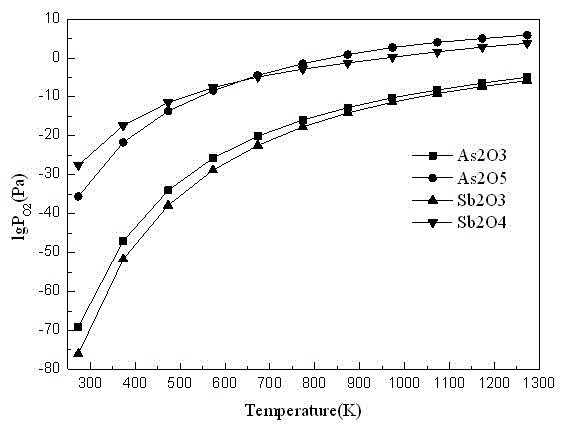

A selective and arsenic recovery technology, applied in the direction of improving process efficiency, can solve the problems of high economic cost, strict requirements for environmental protection and safety measures, and high technical requirements, and achieves the effect of simple process and good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

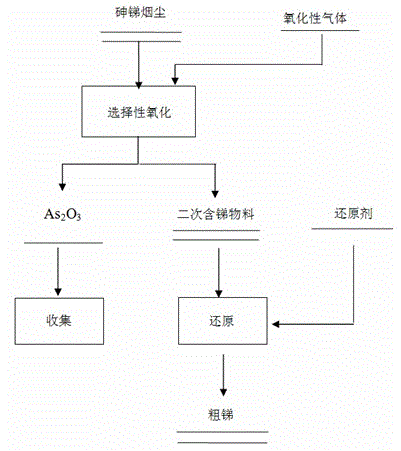

[0027] like figure 2 Shown, this selective oxidation-reduction method reclaims the method for arsenic and antimony in the arsenic and antimony smoke dust, and its concrete steps are as follows:

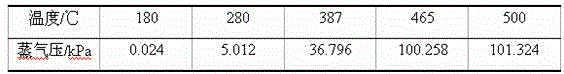

[0028] (1) Selective oxidation recovery of arsenic: Introduce an oxidizing gas with a flow rate of 0.01L / min into the arsenic-antimony fume (the arsenic-antimony fume includes the following components by mass percentage: the arsenic content is 5%, and the antimony content is 30%) , at a temperature of 400°C for 20 minutes, during which the As 2 o 3 Volatile flue gas is collected, and the secondary antimony-containing material is obtained after the reaction is completed, wherein the oxidizing gas is air, As 2 o 3 The collection of volatile flue gas adopts bag dust collection;

[0029] (2) Recover antimony: Add reducing agent to the secondary antimony-containing material obtained in step (1) according to the mass ratio of secondary antimony-containing material to reducing agent is ...

Embodiment 2

[0032] like figure 2 Shown, this selective oxidation-reduction method reclaims the method for arsenic and antimony in the arsenic and antimony smoke dust, and its concrete steps are as follows:

[0033] (1) Selective oxidation recovery of arsenic: Introduce an oxidizing gas with a flow rate of 0.5L / min into the arsenic-antimony fume (the arsenic-antimony fume includes the following mass percentage components: the arsenic content is 20%, and the antimony content is 60%) , reacted at a temperature of 800°C for 90min, during which the As 2 o 3 Volatile flue gas is collected, and the secondary antimony-containing material is obtained after the reaction is completed, wherein the oxidizing gas is oxygen-enriched air, and the As 2 o 3 The collection of volatile flue gas adopts bag dust collection;

[0034] (2) Recovering antimony: add a reducing agent to the secondary antimony-containing material obtained in step (1) according to the mass ratio of the secondary antimony-containi...

Embodiment 3

[0037] like figure 2 Shown, this selective oxidation-reduction method reclaims the method for arsenic and antimony in the arsenic and antimony smoke dust, and its concrete steps are as follows:

[0038] (1) Selective oxidation recovery of arsenic: Introduce an oxidizing gas with a flow rate of 0.4L / min into the arsenic-antimony fume (the arsenic-antimony fume includes the following components by mass percentage: the arsenic content is 15%, and the antimony content is 40%) , react at a temperature of 600°C for 70min, during which the As 2 o 3 Volatile flue gas is collected, and the secondary antimony-containing material is obtained after the reaction is completed, wherein the oxidizing gas is oxygen, and As 2 o 3 The collection of volatile flue gas adopts bag dust collection;

[0039] (2) Recovering antimony: add a reducing agent to the secondary antimony-containing material obtained in step (1) according to the mass ratio of the secondary antimony-containing material to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com