One-well two-bin type quick conveying method for deep tunnel guniting and concreting materials

A technology for pouring concrete and materials, which is applied in earthwork drilling, tunnels, shaft linings, etc. It can solve the problems of restricting the demand for concrete materials, increasing the pressure of auxiliary lifting, and unreasonable return work, and achieves obvious economic and social benefits. and promote the effect of app value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

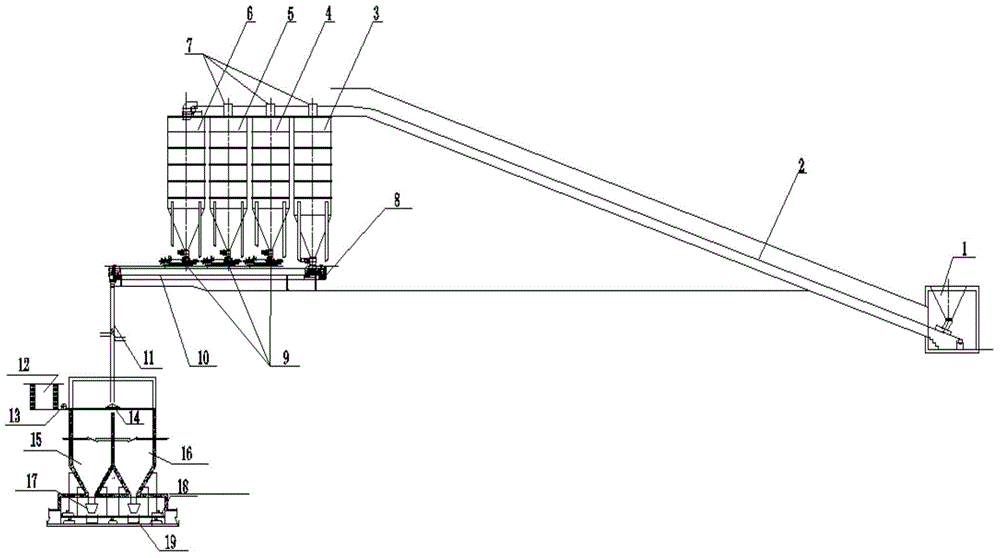

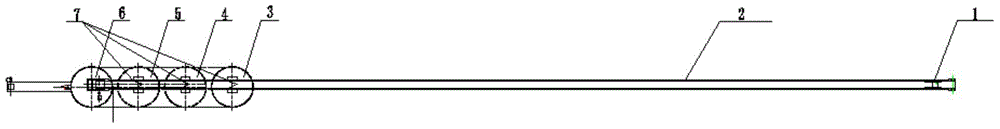

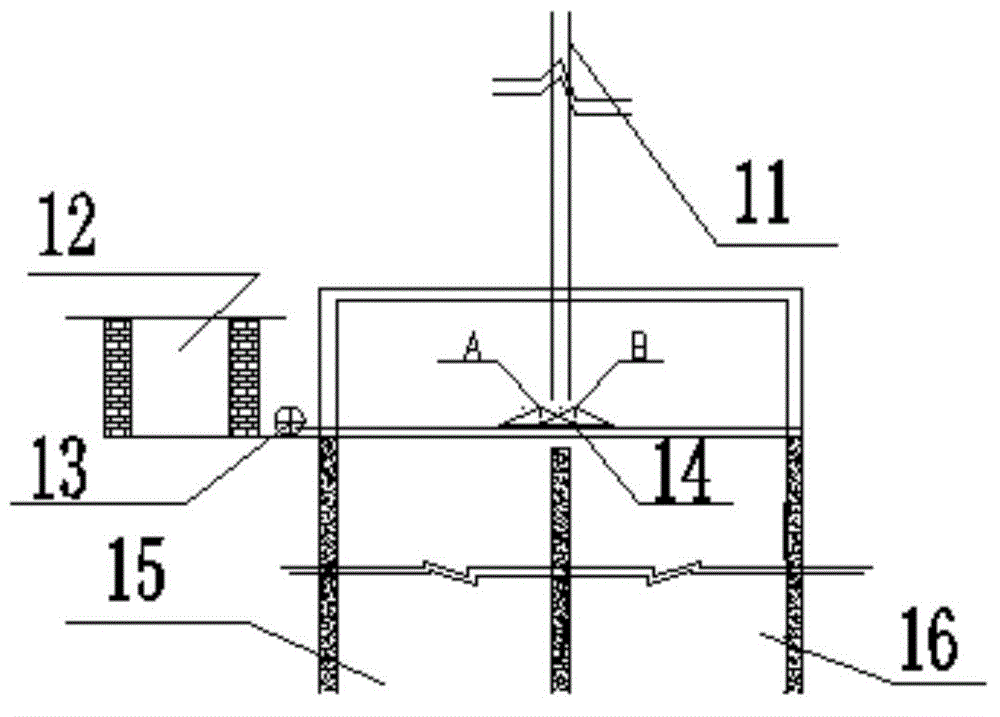

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Such as Figure 1-Figure 5 As shown, the rapid delivery equipment system used in the one well and two warehouse type rapid delivery method for deep roadway grouting and pouring concrete materials includes: receiving funnel 1, and an iron grate is set on the receiving funnel 1, and the filtering area of the iron grate is 40mm ×40mm, to prevent unqualified large-size materials from entering the silo, and reduce the risk of blockage of the feeding pipe during the later feeding process. Stone silo 3, sand silo 4, stone powder silo 5, and cement silo 6 arranged in a line; they are arranged on the top between the feeding funnel 1 and the stone silo 3, sand silo 4, and stone powder silo 5. Material belt conveyor 2; belt conveyor 10 located below the gravel silo 3, sand silo 4, stone powder silo 5 and cement silo 6 to the mouth of the feeding well; st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com