Rotor profile of double-screw compressor

A compressor rotor and twin-screw technology, which is applied in the field of compressors, can solve problems affecting compressor performance and lack, and achieve the effects of eliminating sharp points, small area, and reducing noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

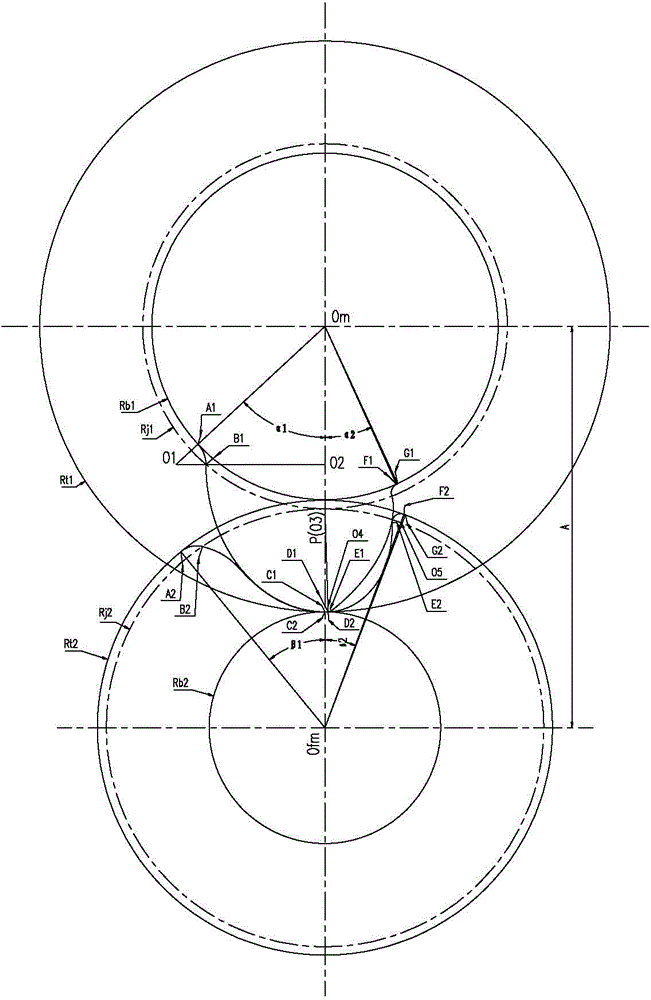

[0015] Such as figure 1 shown.

[0016]A new twin-screw compressor rotor profile, including the male rotor profile 1 and the female rotor profile 2, the gear ratio of the male rotor and the female rotor is 4-6:5-8, which can be adjusted according to low, medium and high exhaust Choose different combinations of pressure conditions such as 4:5, 4:6, 5:6, 5:7, 6:7, 6:8, etc. The tooth shape of the male rotor and the female rotor is a bilateral asymmetrical tooth shape with pin-tooth arcs, arcs and arc envelopes, ellipses and ellipse envelopes, and quadratic curves such as rolling arcs as basic units. The male rotor is composed of five to six quadratic curve units A1B1, B1C1, C1D1, D1E1, E1F1, and F1G1 (F1G1 can be omitted for five-segment curves), and the female rotor is composed of A2B2, B2C2, C2D2, D2E2, E2F2, and F2G2. Five-six quadratic curve un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com