High-efficiency three-claw claw type vacuum pump

A high-efficiency, vacuum pump technology, used in rotary piston pumps, components of pumping devices for elastic fluids, pumps, etc. The effect of volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

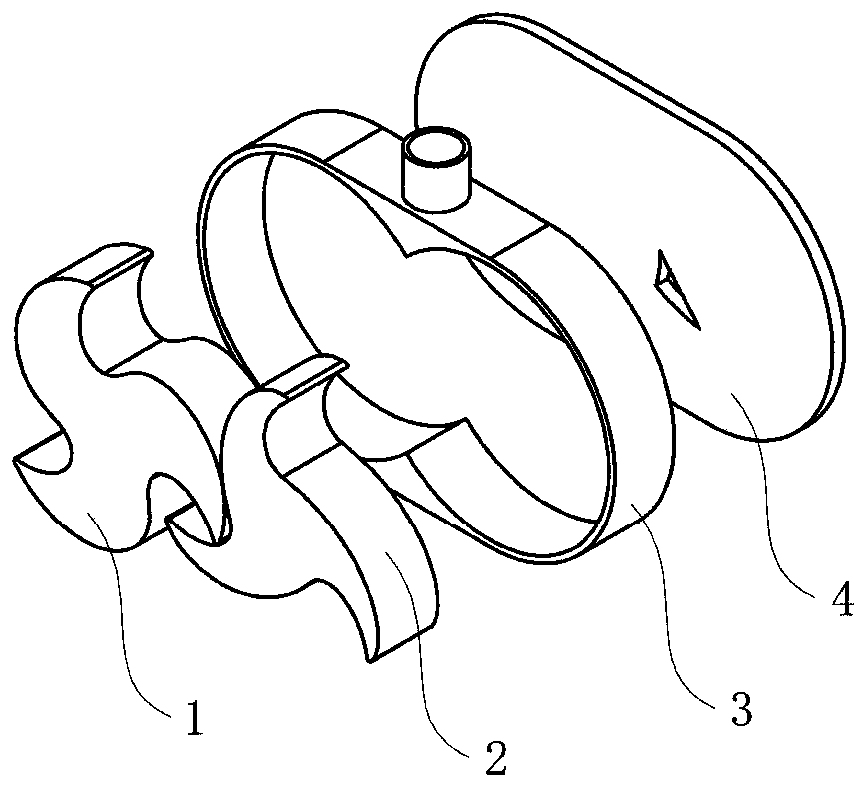

[0049] Such as figure 1 As shown, it is a structural diagram of a three-claw vacuum pump, including a left claw rotor 1, a right claw rotor 2, a cavity 3 and an exhaust end cover 4, and the gas enters the cavity through the radial suction port 301 opened on the cavity 3 3. With the synchronous and opposite double-rotational motion of the left claw rotor 1 and the right claw rotor 2, the gas inhaled in the cavity 3 is transported and compressed in equal volume, and when the gas rotates to the position of the exhaust port, it passes through the exhaust port. The exhaust port 401 on the gas end cover 4 discharges axially.

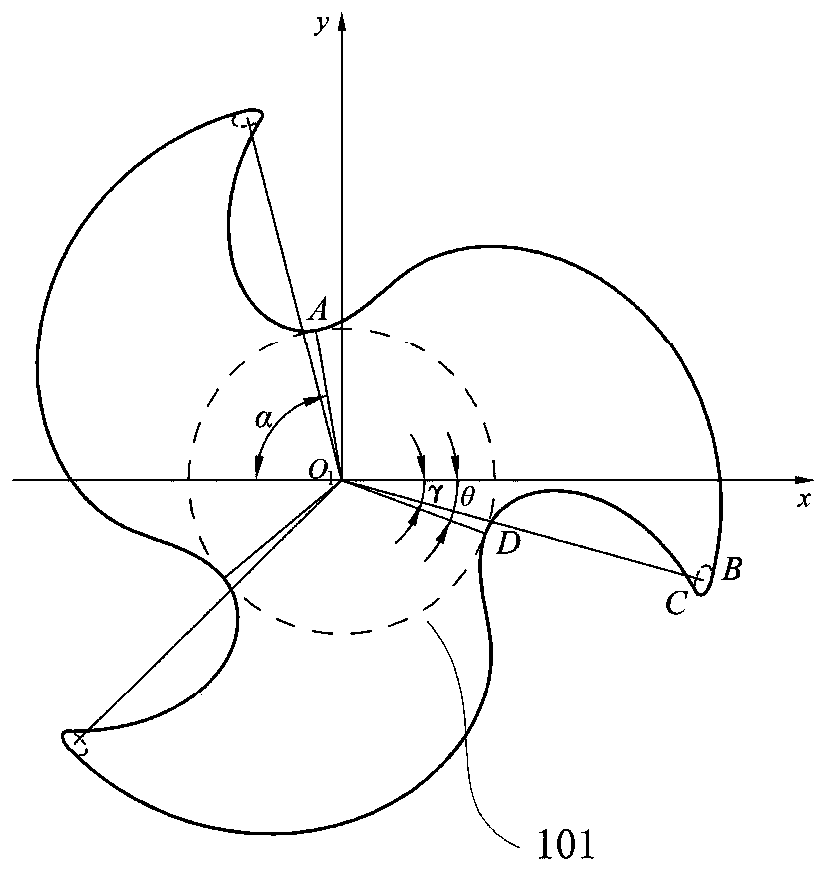

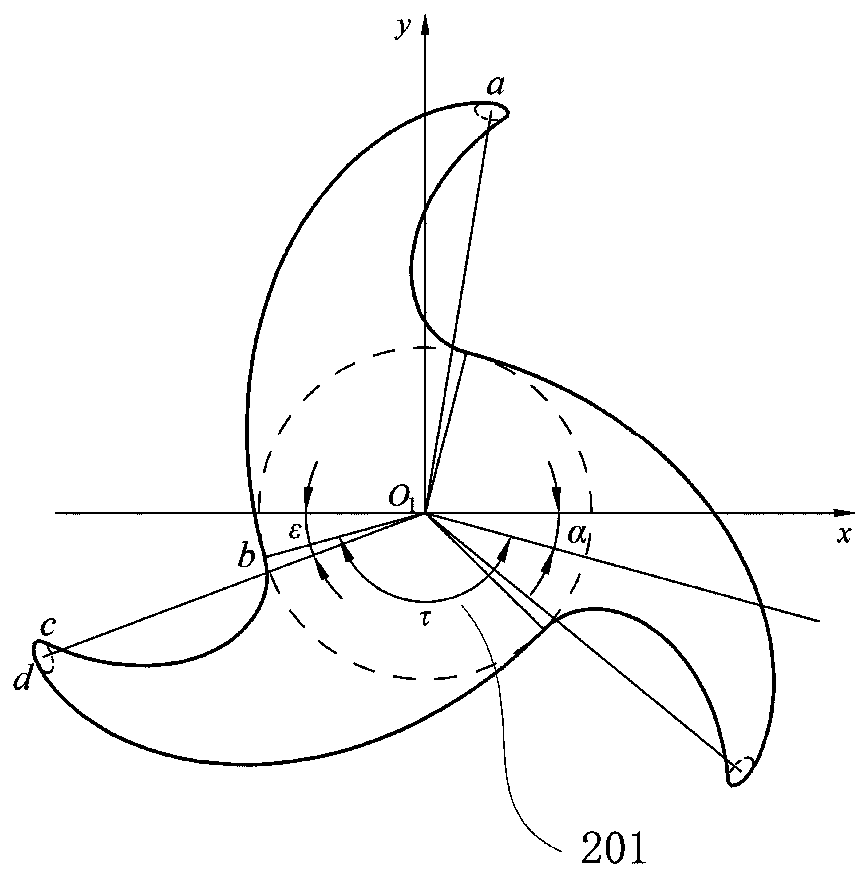

[0050] Such as figure 2 As shown, it is the left profile line diagram of the left claw rotor, the left profile line 101 of the left claw rotor 1 is about its rotation center O 1 Symmetrical to the center of 120°, that is, the left c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com