Double-tooth hydrogen circulating pump rotor set and double-tooth hydrogen circulating pump

A technology of hydrogen circulation and rotor group, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems affecting the overall operation performance of the double-tooth hydrogen circulation pump, rotor wear, shortening the service life of the rotor, etc., so as to improve the service life. , Guarantee the ice breaking ability and the effect of protecting the molding line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

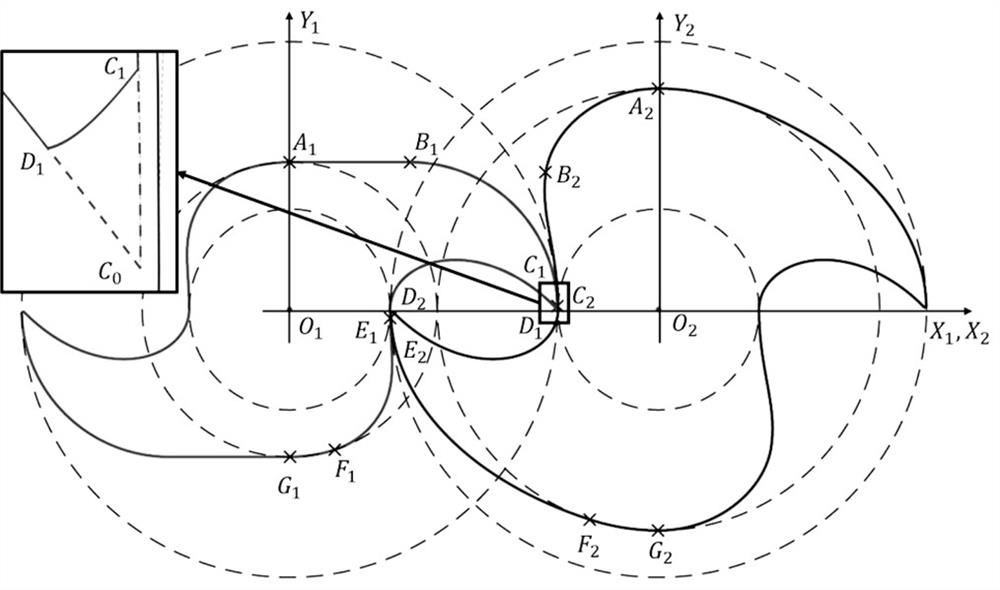

[0038] Such as figure 1 As shown, the double-toothed hydrogen circulation pump rotor set of the present invention includes a first double-toothed screw rotor and a second double-toothed screw rotor. The profile of the first double-toothed screw rotor is a centrally symmetrical figure, including a straight line A connected end to end. 1 B 1 , the first transition arc B 1 C 1 , optimization curve C 1 D. 1 , point meshing cycloid D 1 E. 1 , curve E 1 f 1 , the second transition arc F 1 G 1 and A 1 B 1 , B 1 C 1 、C 1 D. 1 、D 1 E. 1 ,E 1 f 1 , F 1 G 1 Figures that are each symmetrical about the center;

[0039] The profile line of the second twin-tooth screw rotor is a centrally symmetrical figure, including a straight line A connected head to tail 1 B 1 The conjugate envelope A of 2 B 2 , the first transition arc B 1 C 1 The conjugate envelope B of 2 C 2 , with the optimized curve C 1 D. 1 meshing point meshing cycloid C 2 D. 2 , meshing with the ...

Embodiment 2

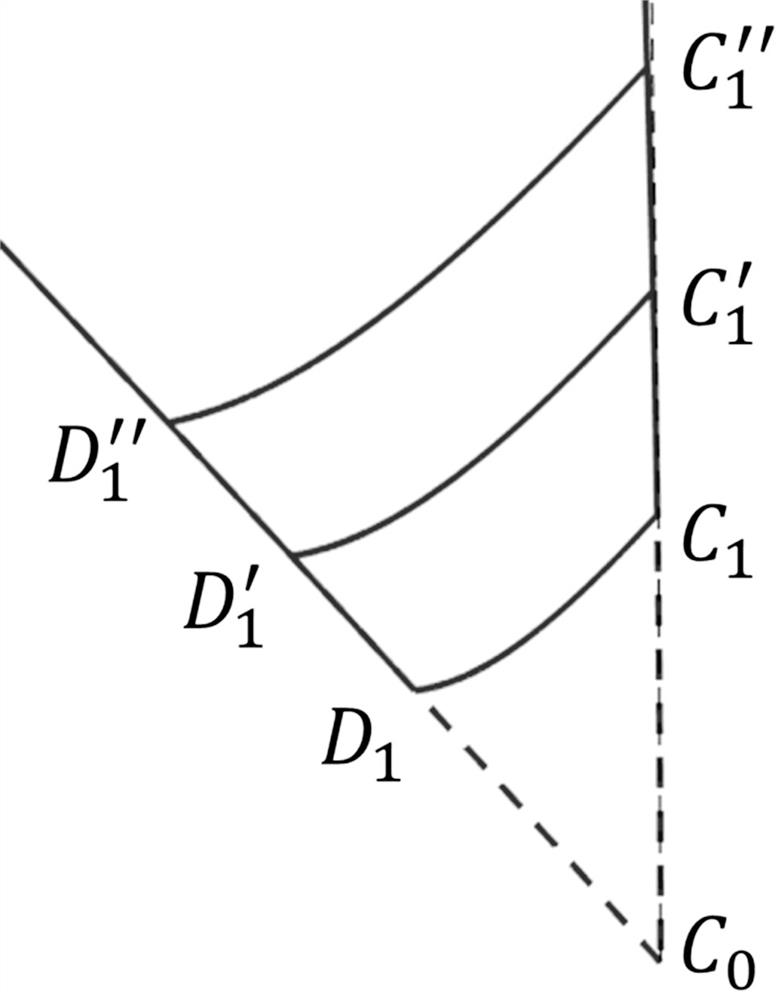

[0056] The difference between the double-tooth hydrogen circulating pump rotor set of this embodiment and that of Embodiment 1 is that the optimization curve C 1 D. 1 Using straight line segments to optimize point meshing cycloids D 1 E. 1 Sharp point C formed with addendum circle 0 , the equation of optimizing the straight line segment is as follows, y013=a*(x013)+b, the first transition arc B 1 C 1 C on 1 Coordinates of points, point meshing cycloid D 1 E. 1 D on 1 Substituting the coordinates of the point into the equation of the above-mentioned optimized straight line segment can obtain the values of parameters a and b, and the specific values are obtained by modeling and calculating with matlab software. In this embodiment, a=0.733, b=-27.9, that is, the equation for optimizing the straight line segment is y013=0.733*(x013)+-27.9. Optimal Curve D 2 E. 2 with the optimized curve C 1 D. 1 Symmetrically, y024 = 0.733*(x024) + -27.9.

Embodiment 3

[0058] The difference between the double-tooth hydrogen circulating pump rotor set of this embodiment and that of Embodiment 1 is that the optimization curve C 1 D. 1 is an arc, and the equation for optimizing the arc is as follows, (x013-a) 2 +(y013-b) 2 = r 2 , radius r according to C 1 with D 1 The length of the connecting line is determined, and the first transition arc B 1 C 1 C on 1 Coordinates of points, point meshing cycloid D 1 E. 1 D on 1 The values of parameters a and b can be obtained by substituting the coordinates of the points into the equation of the above-mentioned optimized arc, and the specific values are obtained by modeling and calculating with matlab software. In the present embodiment, a=32.55, b=0.34, r=0.16, promptly the equation of optimizing circular arc is (x013-32.55) 2 +(y013-0.34) 2 =0.16 2 . Optimal Curve D 2 E. 2 with the optimized curve C 1 D. 1 Symmetrical, (x024-32.55) 2 +(y024-0.34) 2 =0.16 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com