Novel double-screw compressor rotor profile

A compressor rotor and twin-screw technology, applied in the field of compressors, can solve the problems of weak tooth strength and poor processing, and achieve the effects of reducing noise and vibration, eliminating sharp points and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the present invention will be clearly and completely described below with reference to the accompanying drawings in the present invention.

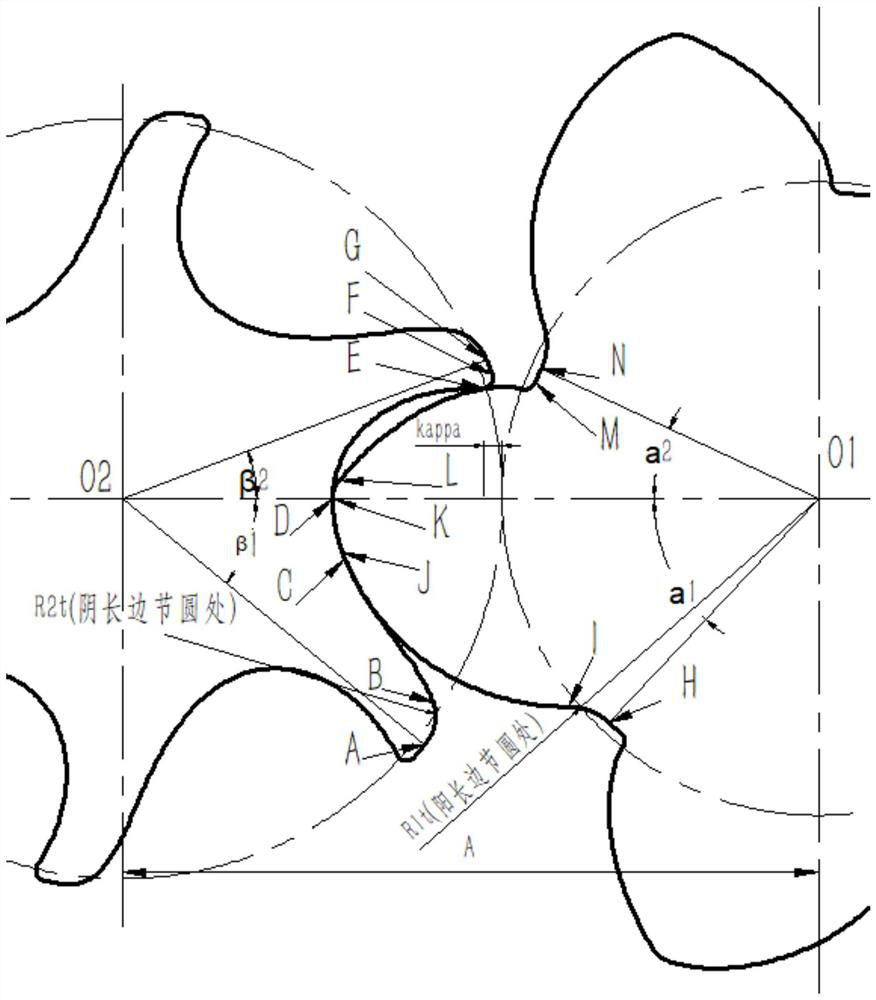

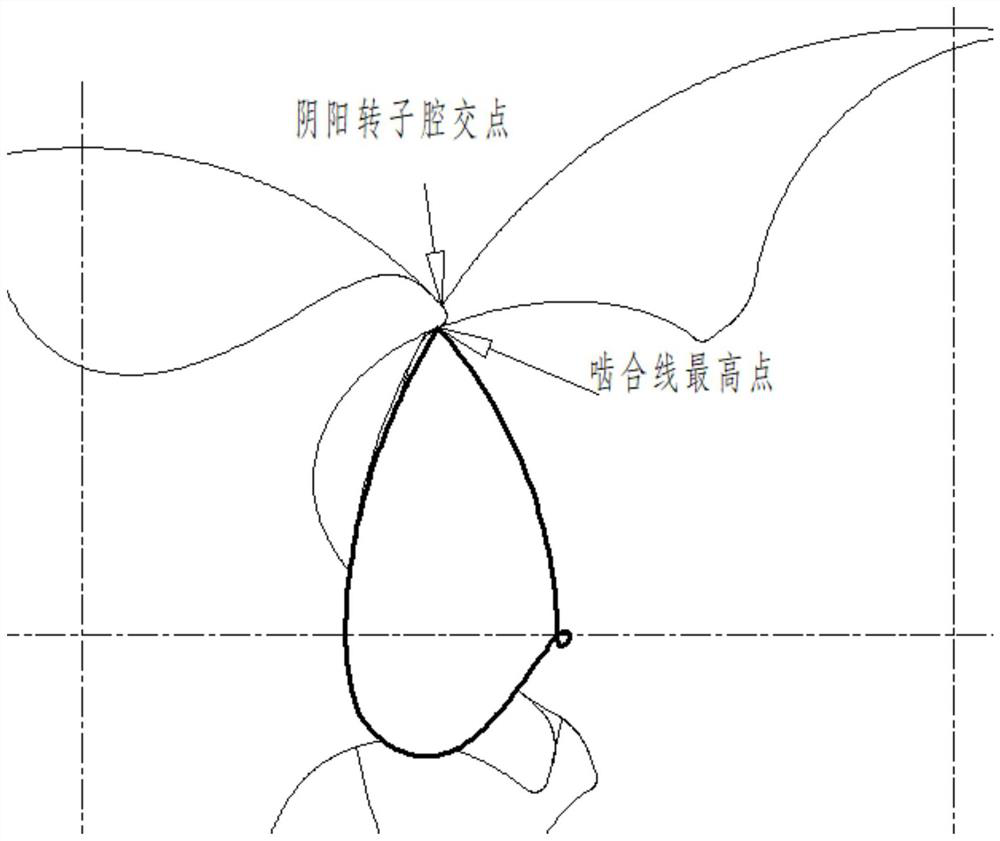

[0027] like Figure 1 to Figure 3 As shown, a new twin-screw compressor rotor profile, including male rotor profile 1 and female rotor profile 2, has a male rotor and a female rotor gear ratio of 4 to 6: 5 to 8; For high exhaust pressure conditions, choose 4:5, 4:6, 5:6, 5:7, 6:7, 6:8 and other different combinations.

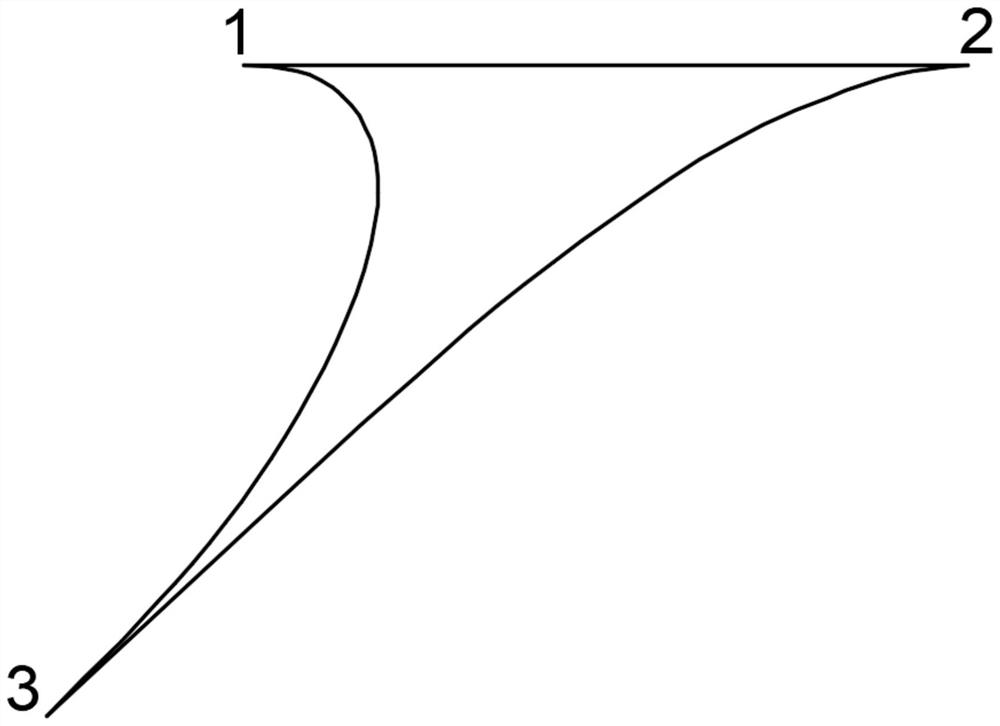

[0028] The tooth shapes of the male rotor and the female rotor are all bilateral asymmetric tooth shapes with circular arc and circular arc envelope as the basic unit.

[0029] The male rotor consists of the first arc HI of the male rotor, the second arc IJ of the male rotor, the third arc JK of the male rotor, the fourth arc KL of the male rotor, the arc envelope LM of the male rotor, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com